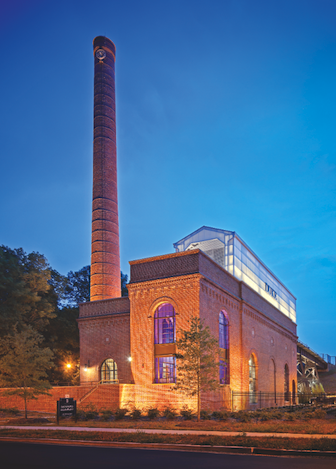

As recently as 2008, Duke University’s East Campus steam plant was an overgrown ruin. The former coal-burning plant had been shuttered for more than 30 years, it was covered in vines, and its roof had turned into a forest. Plant roots tore away at the 80-year-old brick façade, in some cases boring right through the 30-inch-thick walls, cracking them and shifting them out of plane and causing massive damage.

Despite these problems, the university saw value in repurposing the historic facility, and in June 2008, an $18.9 million sustainable renovation began that transformed the 6,341-sf building into a modern, efficient natural gas-burning steam facility. Duke engaged the Building Team of SmithGroup (architect), RMF Engineering (MEP), and Balfour Beatty (GC) to tackle the project, which is seeking LEED Gold.

The plant’s defunct coal-burning equipment was replaced by 15 energy-efficient Miura boilers, specifically chosen because their modular nature allowed them to be squeezed into the existing space better than traditional fire-tube and water-tube boilers. Even so, the Building Team had to construct a mezzanine to allow the new boilers to be stacked vertically. The Miura boilers produce steam much faster than traditional boilers, with a cold-to-steaming rate of less than five minutes, which reduces energy loss associated with startup, purge, and warm-up cycles. The boilers also have a factory-installed feedwater economizer that minimizes waste heat through the flue gas, increasing boiler efficiency by about 5%.

To further increase efficiency, the Building Team incorporated a blowdown heat recovery system that aids water savings by eliminating use of cooling water to temper the blowdown before it enters the sewer system. The coal-to-gas conversion helped Duke reduce its coal consumption by 70%. The facility itself operates 33% more efficiently than a baseline building.

As for the crumbling plant itself, the Building Team took on the restoration of the 1928 facility, which was designed by Horace Trumbauer, the architect behind numerous buildings on the Duke University campus.

Damage caused by years of neglect was remedied by rebuilding areas where masonry couldn’t be repaired, then cleaning and repointing brick that could be saved. A new cast-in-place roof deck was installed, along with a high-albedo, single-ply roof membrane. The building’s existing steel windows could not be salvaged, so they were replaced with new steel units that matched the profile of the originals. Low-e glazing was used on windows in the plant’s conditioned spaces; these same spaces were also insulated for greater efficiency. An old railroad trestle, which at one time brought coal cars up to the roof of the steam plant, was restored and the existing rooftop steel coal shed was rebuilt with corrugated fiberglass panels; now the coal shed glows at night.

In total, the Building Team was able to reuse 90% of the existing facility and diverted 85% of construction waste from landfills, a strong indication of the Building Team’s concerted effort to reuse or repurpose as much existing material as possible. For example, the original coal chutes were reused as part of the plant’s ventilation system; an old deaerator tank was put to use as a rainwater storage tank (rainwater is used within the plant to flush toilets); and old valves and wood floor decking were used to build benches for the terrace. Items that weren’t reused were donated to campus and community arts groups.

The project’s imaginative reuse of old elements and the careful addition of new ones caught the attention of our Reconstruction Awards judges. “It’s so carefully thought out,” said Walker Johnson, principal of Chicago-based Johnson Lasky Architects and honorary chair of the awards panel. “It’s absolutely one of the most unique projects,” said Darlene Ebel, Director of Facility Information Management at the University of Illinois at Chicago.

Summing up the judges’ reaction, George Tuhowski, Director of Sustainability for Leopardo Construction, Hoffman Estates, Ill., said: “They maintained a university icon. It’s functional, but it’s also a showpiece.” BD+C

PROJECT SUMMARY

Building Team

Submitting firm: SmithGroup (architect)

Owner: Duke University

CM: Balfour Beatty

MEP: RMF Engineering

General Information

Size: 6,341 gsf

Construction cost: $18.91 million

Construction time: June 2008 to July 2010

Delivery method: CM at risk

Related Stories

| Aug 11, 2010

AIA approves Sika Sarnafil’s continuing education courses offering sustainable design credits

Two continuing education courses offered by Sika Sarnafil have been approved by the American Institute of Architects (AIA) and are now certified to fulfill the AIA’s new Sustainable Design continuing education requirements.

| Aug 11, 2010

HNTB, Arup, Walter P Moore among SMPS National Marketing Communications Awards winners

The Society for Marketing Professional Services (SMPS) is pleased to announce the 2009 recipients of the 32nd Annual National Marketing Communications Awards (MCA). This annual competition is the longest-standing, most prestigious awards program recognizing excellence in marketing and communications by professional services firms in the design and building industry.

| Aug 11, 2010

'Flexible' building designed to physically respond to the environment

The ecoFLEX project, designed by a team from Shepley Bulfinch, has won a prestigious 2009 Unbuilt Architecture Design Award from the Boston Society of Architects. EcoFLEX features heat-sensitive assemblies composed of a series of bi-material strips. The assemblies’ form modulate with the temperature to create varying levels of shading and wind shielding, flexing when heated to block sunlight and contracting when cooled to allow breezes to pass through the screen.

| Aug 11, 2010

New book provides energy efficiency guidance for hotels

Recommendations on achieving 30% energy savings over minimum code requirements are contained in the newly published Advanced Energy Design Guide for Highway Lodging. The energy savings guidance for design of new hotels provides a first step toward achieving a net-zero-energy building.

| Aug 11, 2010

Perkins+Will master plans Vedanta University teaching hospital in India

Working together with the Anil Agarwal Foundation, Perkins+Will developed the master plan for the Medical Precinct of a new teaching hospital in a remote section of Puri, Orissa, India. The hospital is part of an ambitious plan to develop this rural area into a global center of education and healthcare that would be on par with Harvard, Stanford, and Oxford.

| Aug 11, 2010

Burt Hill, HOK top BD+C's ranking of the nation's 100 largest university design firms

A ranking of the Top 100 University Design Firms based on Building Design+Construction's 2009 Giants 300 survey. For more Giants 300 rankings, visit http://www.BDCnetwork.com/Giants

| Aug 11, 2010

PBK, DLR Group among nation's largest K-12 school design firms, according to BD+C's Giants 300 report

A ranking of the Top 75 K-12 School Design Firms based on Building Design+Construction's 2009 Giants 300 survey. For more Giants 300 rankings, visit http://www.BDCnetwork.com/Giants