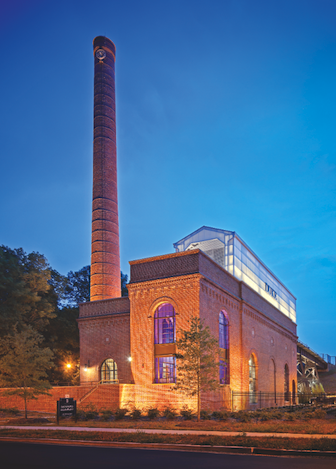

As recently as 2008, Duke University’s East Campus steam plant was an overgrown ruin. The former coal-burning plant had been shuttered for more than 30 years, it was covered in vines, and its roof had turned into a forest. Plant roots tore away at the 80-year-old brick façade, in some cases boring right through the 30-inch-thick walls, cracking them and shifting them out of plane and causing massive damage.

Despite these problems, the university saw value in repurposing the historic facility, and in June 2008, an $18.9 million sustainable renovation began that transformed the 6,341-sf building into a modern, efficient natural gas-burning steam facility. Duke engaged the Building Team of SmithGroup (architect), RMF Engineering (MEP), and Balfour Beatty (GC) to tackle the project, which is seeking LEED Gold.

The plant’s defunct coal-burning equipment was replaced by 15 energy-efficient Miura boilers, specifically chosen because their modular nature allowed them to be squeezed into the existing space better than traditional fire-tube and water-tube boilers. Even so, the Building Team had to construct a mezzanine to allow the new boilers to be stacked vertically. The Miura boilers produce steam much faster than traditional boilers, with a cold-to-steaming rate of less than five minutes, which reduces energy loss associated with startup, purge, and warm-up cycles. The boilers also have a factory-installed feedwater economizer that minimizes waste heat through the flue gas, increasing boiler efficiency by about 5%.

To further increase efficiency, the Building Team incorporated a blowdown heat recovery system that aids water savings by eliminating use of cooling water to temper the blowdown before it enters the sewer system. The coal-to-gas conversion helped Duke reduce its coal consumption by 70%. The facility itself operates 33% more efficiently than a baseline building.

As for the crumbling plant itself, the Building Team took on the restoration of the 1928 facility, which was designed by Horace Trumbauer, the architect behind numerous buildings on the Duke University campus.

Damage caused by years of neglect was remedied by rebuilding areas where masonry couldn’t be repaired, then cleaning and repointing brick that could be saved. A new cast-in-place roof deck was installed, along with a high-albedo, single-ply roof membrane. The building’s existing steel windows could not be salvaged, so they were replaced with new steel units that matched the profile of the originals. Low-e glazing was used on windows in the plant’s conditioned spaces; these same spaces were also insulated for greater efficiency. An old railroad trestle, which at one time brought coal cars up to the roof of the steam plant, was restored and the existing rooftop steel coal shed was rebuilt with corrugated fiberglass panels; now the coal shed glows at night.

In total, the Building Team was able to reuse 90% of the existing facility and diverted 85% of construction waste from landfills, a strong indication of the Building Team’s concerted effort to reuse or repurpose as much existing material as possible. For example, the original coal chutes were reused as part of the plant’s ventilation system; an old deaerator tank was put to use as a rainwater storage tank (rainwater is used within the plant to flush toilets); and old valves and wood floor decking were used to build benches for the terrace. Items that weren’t reused were donated to campus and community arts groups.

The project’s imaginative reuse of old elements and the careful addition of new ones caught the attention of our Reconstruction Awards judges. “It’s so carefully thought out,” said Walker Johnson, principal of Chicago-based Johnson Lasky Architects and honorary chair of the awards panel. “It’s absolutely one of the most unique projects,” said Darlene Ebel, Director of Facility Information Management at the University of Illinois at Chicago.

Summing up the judges’ reaction, George Tuhowski, Director of Sustainability for Leopardo Construction, Hoffman Estates, Ill., said: “They maintained a university icon. It’s functional, but it’s also a showpiece.” BD+C

PROJECT SUMMARY

Building Team

Submitting firm: SmithGroup (architect)

Owner: Duke University

CM: Balfour Beatty

MEP: RMF Engineering

General Information

Size: 6,341 gsf

Construction cost: $18.91 million

Construction time: June 2008 to July 2010

Delivery method: CM at risk

Related Stories

| Aug 11, 2010

A glimmer of hope amid grim news as construction employment falls in most states, metro areas

The construction employment picture brightened slightly with 18 states adding construction jobs from April to May according to a new analysis of data released today by the Bureau of Labor Statistics (BLS). However, construction employment overall continued to decline, noted Ken Simonson, the chief economist for the Associated General Contractors of America.

| Aug 11, 2010

Thom Mayne unveils 'floating cube' design for the Perot Museum of Nature and Science in Dallas

Calling it a “living educational tool featuring architecture inspired by nature and science,” Pritzker Prize Laureate Thom Mayne and leaders from the Museum of Nature & Science unveiled the schematic designs and building model for the Perot Museum of Nature & Science at Victory Park. Groundbreaking on the approximately $185 million project will be held later this fall, and the Museum is expected to open by early 2013.

| Aug 11, 2010

SOM's William F. Baker awarded Fritz Leonhardt Prize for achievement in structural engineering

In recognition of his engineering accomplishments, which include many of the tallest skyscrapers of our time, William F. Baker received the coveted Fritz Leonhardt Prize in Stuttgart, Germany. He is the first American to receive the prize.

| Aug 11, 2010

American Concrete Institute forms technical committee on BIM for concrete structures

The American Concrete Institute (ACI) announces the formation of a new technical committee on Building Information Modeling (BIM) of Concrete Structures.

| Aug 11, 2010

10 tips for mitigating influenza in buildings

Adopting simple, common-sense measures and proper maintenance protocols can help mitigate the spread of influenza in buildings. In addition, there are system upgrades that can be performed to further mitigate risks. Trane Commercial Systems offers 10 tips to consider during the cold and flu season.

| Aug 11, 2010

Reed Construction Data files corporate espionage lawsuit against McGraw-Hill Construction Dodge

Reed Construction Data (RCD), a leading construction information provider and a wholly-owned subsidiary of Reed Elsevier (NYSE:RUK, NYSE:ENL), today filed suit in federal court against McGraw-Hill Construction Dodge, a unit of The McGraw-Hill Companies, Inc. (NYSE:MHP). The suit charges that Dodge has unlawfully accessed confidential and trade secret information from RCD since 2002 by using a series of fake companies to pose as RCD customers.

| Aug 11, 2010

Jacobs, HOK top BD+C's ranking of the 75 largest state/local government design firms

A ranking of the Top 75 State/Local Government Design Firms based on Building Design+Construction's 2009 Giants 300 survey. For more Giants 300 rankings, visit http://www.BDCnetwork.com/Giants

| Aug 11, 2010

Brad Pitt’s foundation unveils 14 duplex designs for New Orleans’ Lower 9th Ward

Gehry Partners, William McDonough + Partners, and BNIM are among 14 architecture firms commissioned by Brad Pitt's Make It Right foundation to develop duplex housing concepts specifically for rebuilding the Lower 9th Ward in New Orleans. All 14 concepts were released yesterday.

| Aug 11, 2010

NAVFAC releases guidelines for sustainable reconstruction of Navy facilities

The guidelines provide specific guidance for installation commanders, assessment teams, estimators, programmers and building designers for identifying the sustainable opportunities, synergies, strategies, features and benefits for improving installations following a disaster instead of simply repairing or replacing them as they were prior to the disaster.

| Aug 11, 2010

City of Anaheim selects HOK Los Angeles and Parsons Brinckerhoff to design the Anaheim Regional Transportation Intermodal Center

The Los Angeles office of HOK, a global architecture design firm, and Parsons Brinckerhoff, a global infrastructure strategic consulting, engineering and program/construction management organization, announced its combined team was selected by the Anaheim City Council and Orange County Transportation Authority (OCTA) to design phase one of the Anaheim Regional Transportation Intermodal Center.