Cobalt Stables was the kind of project that contractors dream of, where the client wants to build the best facility of its kind, has the budget to do it, and has faith in the contractor to let him express his craft and creativity. The facility in question is an unusual combination of horse stables and training facilities with a comfy human residence, all together under one roof. It presented the best kind of challenges to Star builder Weigel Construction, testing their construction skills at marrying different building usages and different construction materials into a unified whole, and their contractor’s expertise at satisfying the codes for two different types of occupancies under a single roof. The dream came to life by joining together four Star metal buildings and adding a whole lot of TLC. The project was such an elegant success that it was selected by Star builders across the country to receive the 2016 Builder’s Choice Master Builder Award.

Cobalt Stables was built to train Morgan horses in the best possible environment. “This wasn’t the kind of hard-bid job where they’re only looking at bottom line cost,” explains Weigel Construction owner Joe Weigel. “That wasn’t what this project was about. It was about trying to create a facility that was second to none in this local area. We all looked at this and said, it’s a non-typical project that you can put on your belt and show people. So everybody, all our people and the subcontractors, they all treated it as though it was their own. We thought it out before we built it and paid attention to every detail.”

The facility is made of one large, clear-span metal building, with three smaller buildings attached in the form of a cross. Front-and-center is the living quarters, 36’ x 71’ metal building frame with two-story wood framing construction inside it, a full 5,000 sf of living space. Extending seamlessly to the left and right of the living quarters are two 2,160 sf structures that appear to be wings of the house, but are in fact stables and associated horse-space. Behind all of it is a 16,000 sf indoor equestrian arena, an 80-foot wide clear span building with high ceilings.

The exterior walls of the three front elements all feature wood rough carpentry infill for the first ten feet up from the slab. Above that level, it’s more typical metal construction. These three buildings feature an exterior skin of Star PBR metal panels, attached to both wood framing lower down and steel purlins higher up. The interior of the stables is finished solid red oak tongue-and-groove panels. It’s topped off by a composition shingle roof.

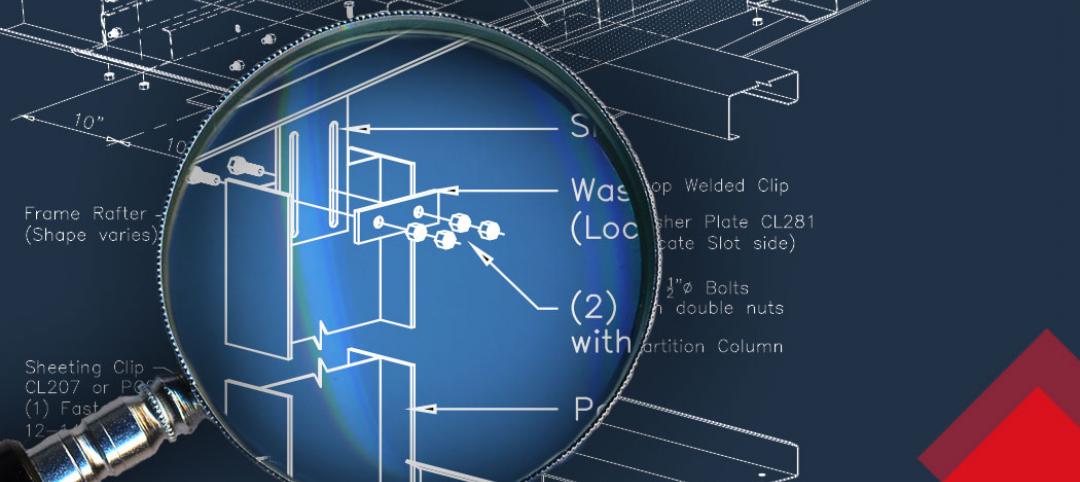

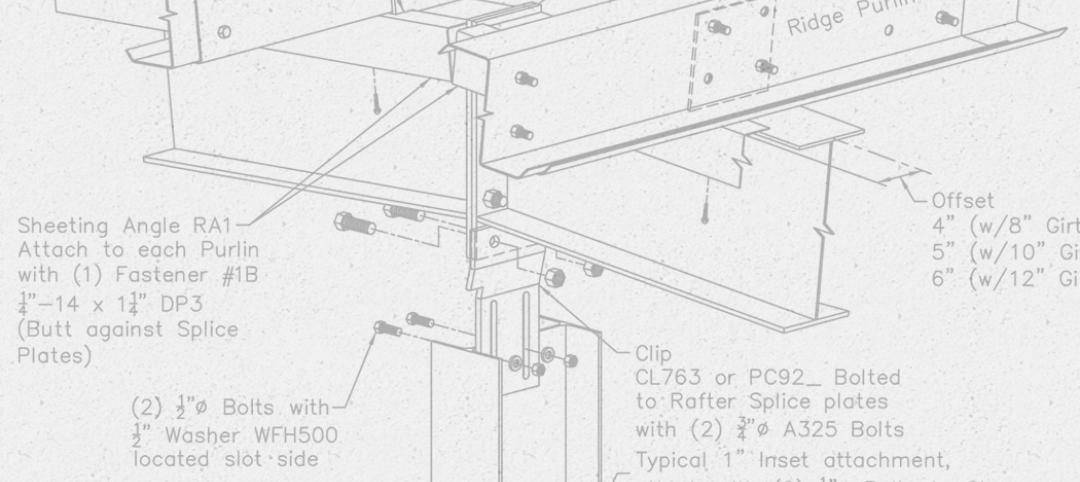

“Integrating wood and steel structures,” Joe Wiegl points out, “requires coordinating things you normally don’t deal with. It goes all the way down to having the right type of fastener going from wood into steel. You can’t just use a generic fastener that’s usually used wood-to-wood or steel-to-steel. Using two types of materials was definitely a challenge.”

The arena section is more typical metal building construction, with steel purlins throughout supporting PBR walls and roof panels.

Perhaps the most unusual aspect of the project was the different types of occupancies being joined together. “As far as the living quarters vs. the stables, you’re dealing with completely different environments. The living quarters is a conditioned area that you want to be quiet, and right outside of that are potentially 20 live horses. The horses are creating their own heat load in a non-conditioned area in the stables. You’re dealing with a much different scenario from one wall to the next. There’s also an occupancy separation in terms of building codes, with a fire wall separating the two areas.”

A great deal of attention was paid to the questions of insulation and maintaining comfortable occupancy temperatures. In the living quarters and stables, spray foam insulation fills the wall cavities, a Star liner panel insulates the roof, and all the floor slabs were built with radiant heating. The arena building, by contrast, is un-insulated, but has a series of two-inch gas pipe radiant heaters that run down the long sides of the arena a few feet below the ceiling.

Ground was broken in Feb. 2016, with considerable sitework being necessary. The project was completed at the beginning of December 2016. After six months of operation, there have been no issues with any of the installations. The owner is happy.

“We’ve been doing this a long time,” observes Weigel. “We know what looks good and what doesn’t. When an owner lets you do what you know, from a contractor’s standpoint, you’re blessed with a project you can be proud of.”

Related Stories

| Apr 17, 2014

6 details that can throw off your schedule

In 1997, Apple told us to “Think Different.” So we did. We thought about what could happen if the world went mobile, if information was boundless, if we could carry our office in our back pocket. We’ve grown to love different and to expect change. And when it comes to Apple products, that’s not such a bad thing. When it comes to your building order, however, it’s not nearly as appealing.

| Apr 9, 2014

Steel decks: 11 tips for their proper use | BD+C

Building Teams have been using steel decks with proven success for 75 years. Building Design+Construction consulted with technical experts from the Steel Deck Institute and the deck manufacturing industry for their advice on how best to use steel decking.

| Apr 8, 2014

Reflecting on job number 61-001

Job number 61-001 changed everything. It was sold in 1961, a year of change for the nation and for Star. By January, John F. Kennedy would be president. By the end of the year, Star would launch a historic shift in our product and our distribution, a shift still active today.

| Mar 31, 2014

Tips for creating a competitive bid using codes and loads

Landing a project feels like winning a prize, sort of like finding that forgotten $20 bill in the pocket of a pair of jeans you haven’t worn in a while. But living on the “chance” of winning a job isn’t a great way to pay your electric bill. So, how do you swing the chances in your favor?

| Mar 26, 2014

A sales and service showcase

High Plains Equipment, a Case IH dealership in Devils Lake, N.D., constructs a larger facility to better serve its customers.

| Mar 19, 2014

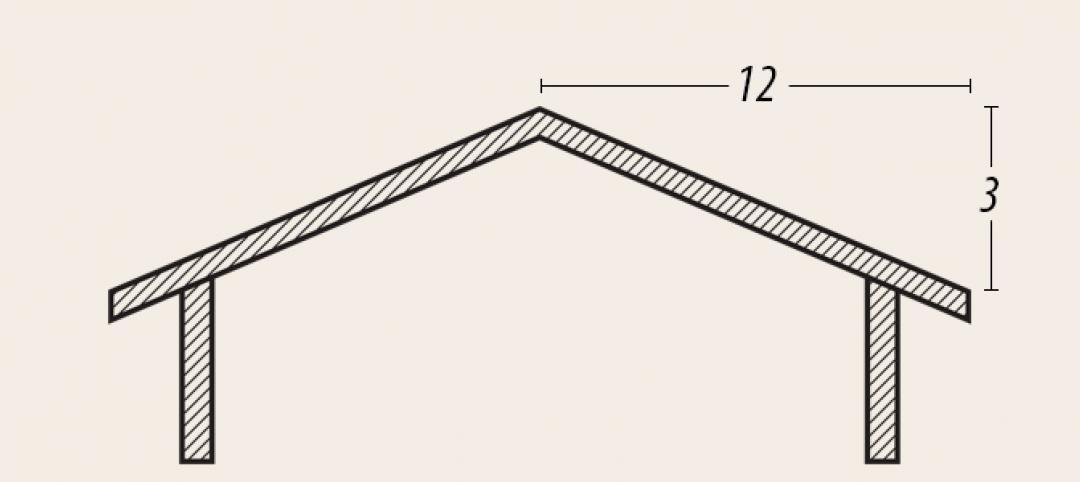

Frames: the biggest value engineering tip

In every aspect of a metal building, you can tweak the cost by adjusting the finish, panel thickness, and panel profile. These changes might make a few percentage points difference in the cost. Change the framing and you have the opportunity to affect 10-20 percent savings to the metal building portion of the project.

| Mar 11, 2014

Why you should start with a builder, part three

We had worked together for 30 years. As a long-standing client of mine, he and I had gone through many projects together. And we were approaching another project, one that would forever change how he viewed our working relationship. As my customer and I sat down to talk about the project details, he told me something that would stay with me for weeks. “Kim, I’m going to have to get other bids on this just so I have peace of mind.”

Sponsored | | Mar 10, 2014

A high-performance barn

Bastoni Vineyards replaces a wooden barn with an efficient metal building used for maintenance, storage, and hosting events.

| Mar 4, 2014

CENTRIA Demonstrates Commitment to Contractors

New Brochure Highlights Architectural Metal Panel Manufacturer’s Products, Expertise and Experience

| Feb 27, 2014

Colorado Coalition Plans Welcoming Events for METALCON International Visitors

Visitors to the 24th METALCON International, slated for October 1-3 at the Colorado Convention Center in Denver, will get a royal welcome from local companies involved in the show. Denver-based New Tech Machinery and Colorado Springs-based S-5! Solutions have formed the Colorado Coalition as a way of encouraging visitors to learn about Colorado before they arrive and for Coloradans to experience METALCON.