Is there a secret to competitive bidding?

Not a secret, but there are certainly ways to find a better price–and some work better than others. If there was a magic bullet, that one tool in your tool belt you just couldn’t live without, then value engineering would be it. Call it the duct tape of competitive bidding.

In every aspect of a metal building, you can tweak the cost–adjust the finish, the panel thickness, panel profile. These are all possible adjustments that will create pricing decreases.

Typically these kind of panel adjustments might make just a few percentage points difference, if that. Primary framing, however, is more like the value engineering homerun. Frames usually represent 30 to 40 percent of the total metal building cost. Change the framing and you have the opportunity to affect 10 to 20 percent savings to the metal building portion of the project.

One of the most effective framing solutions is increasing the roof slope in clear span buildings that are more than 80 feet wide. As the roof slope goes up, the pricing comes down. Here’s how it works:

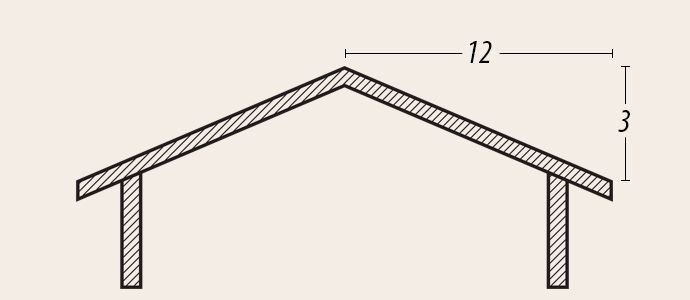

Let’s say you are building a 200-foot soccer complex. With a 1 to 12 roof slope, any roof weight, such as snow, pushes down on the complex and creates a lot of kick out on the columns. There is a lot of outward force because the roof structure is almost flat. To counter this, you have larger rafters and columns.

Now, let’s change the roof slope to a 3 on 12.

By transforming our soccer complex into a more arched structure with the roof slope increase you’ve created a structure that will use smaller rafters and columns.

A larger roof span increases your roof slope but saves you money.

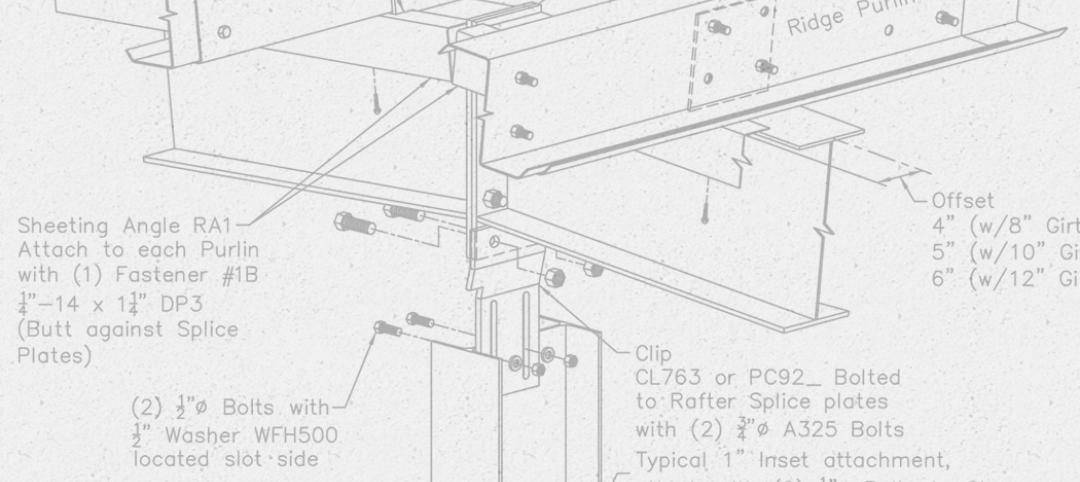

Whenever I offer this solution, one of the first questions I get asked is: But won’t that mean more roof panels, more end wall panels and more end wall girts? Yes. It will. However, even with that extra material, you will be saving so much on the frames that you will still net savings.

If you only have the opportunity to do one value engineering change, this is it. In clear span buildings over 80 feet, this is you hitting one out of the park.

Read more on the Starbuildings blog.

Editor's Note: This is sponsored content. All text and graphics were provided by the sponsor company.

More from Author

Bryan Arlington | Dec 1, 2016

The evolution of codes

Today’s codes define more efficient, effective structures, but the engineering of them has become vastly more complex.

Bryan Arlington | Nov 21, 2016

Ready for earthquakes?

There is a mistaken belief among some people that steel buildings do not do well in earthquakes. The truth is quite the opposite.

Bryan Arlington | Aug 24, 2016

Rolling Sheet Door Considerations

The pros and cons of a rolling sheet door

Bryan Arlington | Aug 19, 2016

Standards. Do You Have Them?

Metal building standard for contractors and erectors.

Bryan Arlington | Apr 24, 2015

Are metal roofs lightning magnets?

According to The Metal Construction Assocition, a metal roof will not make lightning more likely to strike, but it may make a lightning strike less dangerous if it occurs. That’s right, less dangerous, not more.

Bryan Arlington | Mar 31, 2014

Tips for creating a competitive bid using codes and loads

Landing a project feels like winning a prize, sort of like finding that forgotten $20 bill in the pocket of a pair of jeans you haven’t worn in a while. But living on the “chance” of winning a job isn’t a great way to pay your electric bill. So, how do you swing the chances in your favor?

Bryan Arlington | Jan 6, 2014

What is value engineering?

If you had to define value engineering in a single word, you might boil it down to "efficiency." That would be one word, but it wouldn’t be accurate.