Recent global fire events have shed light on the significance of local code compliance in high-rise construction. Although the current focus on metal composite materials (MCM) doesn’t adequately address the entire building envelope ─ which includes many additional components ─ it does provide an opportunity for architects and general contractors to brush up on their role in helping ensure safety.

MCM has been around since the early 70s and has proven to be one of the most versatile architectural cladding products available. Its adaptability, lightweight nature, ease of fabrication and selection of hundreds of colors and finishes help architects and designers achieve nearly any exterior (or interior) aesthetic. But, as with all building products, specifying MCM comes with compliance responsibilities.

There are guidelines to help specifiers understand the codes surrounding when to use traditional polyethylene core (PE) and when a fire-retardant core is required. “A good place to start when researching MCM codes is the 2015 International Building Code,” said James Moses, Technical Service Manager for ALPOLIC®, a leading MCM manufacturer. “The section’s first 10 subsections relate to specifying compliant cladding material for any type of building and height. The last four subsections review compliance for special situations.”

Moses says as a general rule, a fire retardant core must be used when MCM is placed above 40 feet. A PE core is code-compliant for most structures 40 feet high and under (roughly four stories). But once a building goes above 40 feet, in most cases, a fire-retardant core which meets the NFPA 285 standard, a well-established fire-test standard that demonstrates upward resistance to flame spread, must be used.

“The NFPA285 is a test not just for the MCM material, but the entire wall assembly,” said Moses. “This ensures that the entire cladding system has been tested and passed.”

According to Moses, another way to ensure product safety is to look for manufacturers that hold independent, third-party evaluation. The International Code Council Evaluation Service (ICC-ES) offers architects unbiased verification of MCM code compliance. MCM products that are supported with impartial, mainstream code compliance reports are recommended.

Moses also suggests using only MCM products that carry the Warnock Hersey (WH-ETL) Mark. These are products that have been certified-compliant by the building and construction industry’s most rigorous product testing organization. Maintaining the WH-ETL Mark is a continuous process, requiring quarterly inspection audits from Warnock Hersey to ensure ongoing compliance. This is especially important as the industry is starting to see more and more off-shore MCM manufacturers compromising the code by using MCM that does not meet code requirements.

“MCM, like any other building product, is safe when used in compliance with code,” said Moses. “Understanding the code and which products to use will help ensure we continue to build buildings that are as safe as they are beautiful.”

For more information about MCM and fire safety, click here.

Related Stories

Sponsored | Cladding and Facade Systems | Mar 15, 2023

Metal cladding trends and innovations

Metal cladding is on a growth trajectory globally. This is reflected in rising demand for rainscreen cladding and architectural metal coatings. This course covers the latest trends and innovations in the metal cladding market.

Codes | Mar 2, 2023

Biden Administration’s proposed building materials rules increase domestic requirements

The Biden Administration’s proposal on building materials rules used on federal construction and federally funded state and local buildings would significantly boost the made-in-America mandate. In the past, products could qualify as domestically made if at least 55% of the value of their components were from the U.S.

AEC Innovators | Feb 28, 2023

Meet the 'urban miner' who is rethinking how we deconstruct and reuse buildings

New Horizon Urban Mining, a demolition firm in the Netherlands, has hitched its business model to construction materials recycling. It's plan: deconstruct buildings and infrastructure and sell the building products for reuse in new construction. New Horizon and its Founder Michel Baars have been named 2023 AEC Innovators by Building Design+Construction editors.

Sponsored | Metals | Jan 16, 2023

Breaking The Mold: ALPOLIC MCM Accomplishes A+ Design for Ohio School

From the start, the vision for Dayton’s Northridge Local Schools included a standout architectural element. Taking inspiration from the polar bear mascot, Levin Porter Architects created an unforgettable iceberg feature with the help of ALPOLIC. Custom white MCM panels shimmer and provide a local landmark for the community.

75 Top Building Products | Nov 30, 2022

75 top building products for 2022

Each year, the Building Design+Construction editorial team evaluates the vast universe of new and updated products, materials, and systems for the U.S. building design and construction market. The best-of-the-best products make up our annual 75 Top Products report.

Sponsored | Metals | Nov 10, 2022

Largest Tulip Bulb Forcing Farm Rebuilds from Ground Up

Metl-Span insulated metal panels delivered the optimal solution for the new Pioneer Flower Farms facility to rebuild after a fire. The warehouse included the installation of movable freezers and cold storage areas.

Sponsored | Metals | Nov 9, 2022

Making a Difference: Lakeshore Lofts Brings Sustainability and Support with Inspiring Designs

Lakeshore Lofts sets a new standard for affordable housing providing expansive services and support and inspiring sustainable design made possible with ALPOLIC.

Building Materials | Nov 2, 2022

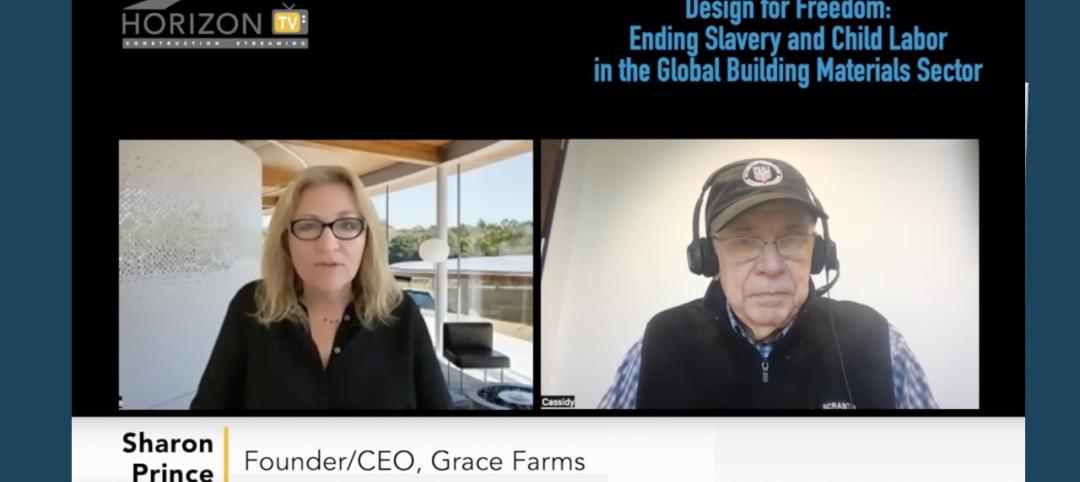

Design for Freedom: Ending slavery and child labor in the global building materials sector

Sharon Prince, Founder and CEO of Grace Farms and Design for Freedom, discusses DFF's report on slavery and enforced child labor in building products and materials.

Sponsored | Metals | Oct 13, 2022

The Benefits of Insulated Metal Panels Over Tilt-Up Walls

When it comes time to choose a building envelope material, project teams can select from a wide array of options. Tilt-up walls can offer some savings, but one system leads the industry for installation, energy, and cost efficiencies: Insulated metal panels.