Months ago we heard news of the “nation’s first carbon-positive hotel”—a 13-floor, 130-000-sf cement tower with a triangular layout and eye-shaped windows. Populus, designed by Studio Gang and developed by Urban Villages, broke ground in Denver, Colo., last year with plans to be operational by summer 2024. What makes Populus a carbon-positive project is a collection of variables, from minimizing waste to using fewer finish materials. But there’s one huge driver behind the green initiative: sustainable concrete.

ECOPact is an optimized, low-carbon concrete made from large amounts of supplementary cementitious materials (SCM). With lower embodied carbon content compared to conventional concrete, ECOPact aims to be an attractive alternative for sustainability-driven engineers.

Sustainable concrete: ECOPact

Designed by Holcim, a sustainable building materials supplier, ECOPact offers a low-carbon alternative that not only meets, but exceeds the properties of standard (CEM I) concrete. This allows the material to be used in all traditional applications: structural components like foundations, columns and beams; to walls, driveways, bridges, and more.

ECOPact Tiers

Rather than having a one-size-fits-all product, Holcim delivers ECOPact in a three-tiered system:

- ECOPact (30–50% reduction in carbon emissions)

- ECOPact Prime (50–70% reduction)

- ECOPACT Max (70–90% reduction)

Each tier can be enhanced with the addition of recycled concrete aggregates ECOPact+ range, according to the company. Kevin Peart, Senior Vice President and General Manager of the Mountain Region, Holcim, believes that Holcim has become “one of the first movers in the concrete industry.”

For the Populus hotel, this sustainable concrete was integral to the design process. The project’s utilization of ECOPact accounts for 65% of the total cubic yards of concrete poured, with an anticipated reduction of 765 tons in the concrete's embodied carbon compared to traditional concrete.

A similar story is told at 55 H Street, a Georgetown University residence hall (above). The project team had a specific challenge: they needed a concrete blend capable of attaining a 28-day design strength of 5,000 psi, while also achieving a high-early strength of 3,000 psi within a span of two to three days. ECOPact delivered, and 55 H Street became “one of the most sustainable buildings in D.C.,” says Zachary Lovett, Project Pursuit Manager, Holcim.

As the built environment continues to find ways to reduce its impact on the planet, innovative materials like ECOPact may help drive the change that architects, engineers, and contractors desire.

Related Stories

| May 14, 2013

Paints and coatings: The latest trends in sustainability

When it comes to durability, a 50-year building design ideally should include 50-year coatings. Many building products consume substantial amounts of energy, water, and petrochemicals during manufacture, but they can make up for it in the operations phase. The same should be expected from architectural coatings.

| Apr 23, 2013

Building material innovation: Concrete cloth simplifies difficult pours

Milliken recently debuted a flexible fabric that allows for concrete installations on slopes, in water, and in other hard to reach places—without the need for molds or mixing.

| Apr 19, 2013

Must see: Shell of gutted church on stilts, 40 feet off the ground

Construction crews are going to extremes to save the ornate brick façade of the Provo (Utah) Tabernacle temple, which was ravaged by a fire in December 2010.

| Mar 29, 2013

Shenzhen projects halted as Chinese officials find substandard concrete

Construction on multiple projects in Guangdong Province—including the 660-m Ping'an Finance Center—has been halted after inspectors in Shenzhen, China, have found at least 15 local plants producing concrete with unprocessed sea sand, which undermines building stabity.

| Mar 4, 2013

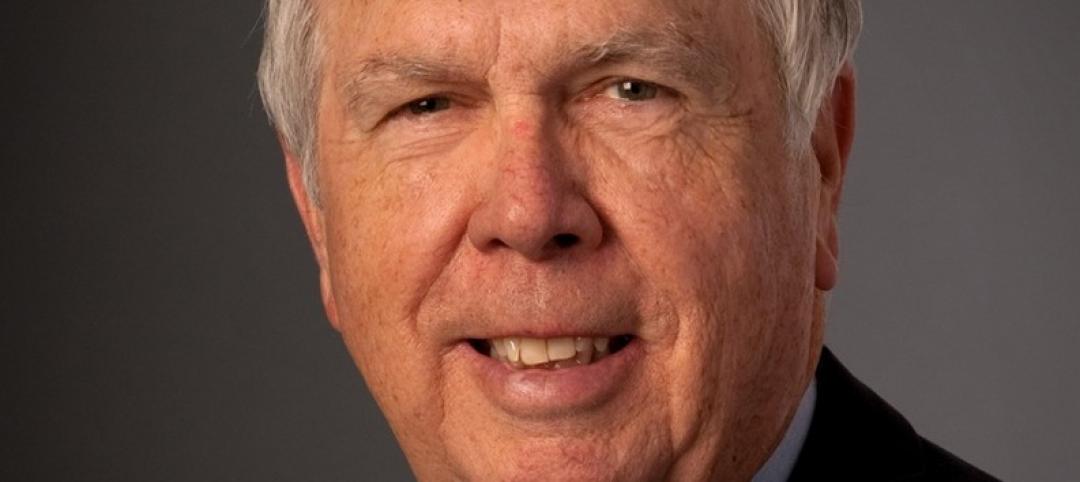

Legendary structural engineer Gene Corley passes away at 77

CTLGroup, an expert engineering and materials science firm located in Skokie, Illinois, is saddened by the news that W. Gene Corley, Ph.D., S.E., P.E., Senior Vice President, died on March 1, 2013 after a brief battle with cancer.

| Feb 25, 2013

Turner employs rare 'collapsible' steel truss system at Seattle light rail station

To speed construction of the $110 million Capitol Hill Station light-rail station in Seattle, general contractor Turner Construction will use an unusual temporary framing method for the project's underground spaces.

| Feb 22, 2013

Dutch team's 'bioconcrete' can heal itself

Two researchers from Delft Technical University in Holland have developed a self-healing cement that can stop microcracks from forming in concrete.

| Jan 3, 2013

5 things you should know about decorative concrete

Designing and installing decorative concrete is a lot more difficult that you might think. A veteran of many such installations offers a handful of tips to help you plan your next decorative concrete project.

| Sep 24, 2012

Reed Construction completes Lafarge headquarters in Chicago

Reed Construction was contracted to complete the full third floor build-out which included the construction of new open area work space, private offices, four conference rooms with videoconferencing capabilities and an executive conference boardroom.

| Aug 30, 2012

Holcim (US) announces new Deputy Chief Executive Officer

Ruiz began his career with the Holcim Group in 1986 as electrical supervisor with Holcim Apasco, Mexico, later becoming plant manager.