The Pavilion, Penn Medicine’s $1.5 billion hospital, hopes to make waves in the medical world once it is completed. With a cornucopia of state-of-the-art features, the Foster + Partners-designed hospital is expected to provide a new level of patient care.

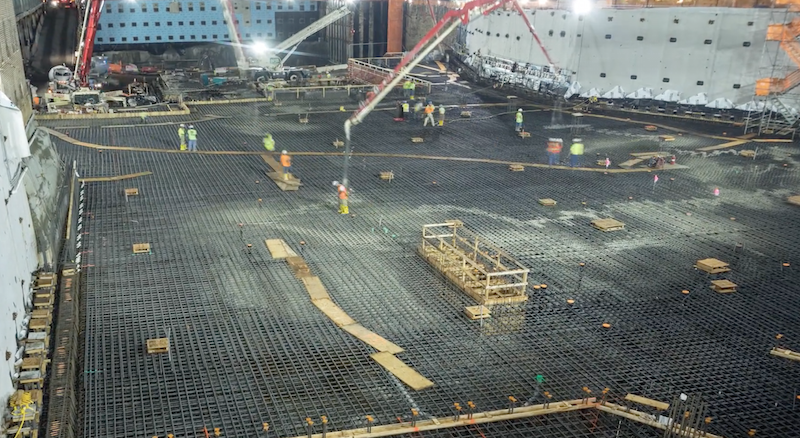

Before any of that happens, though, the hospital has already accomplished something no Philadelphia hospital, or any other structure for that matter, has accomplished before. On July 8, the Pavilion set the record for the largest concrete pour in Philadelphia’s history, Philly Voice reports.

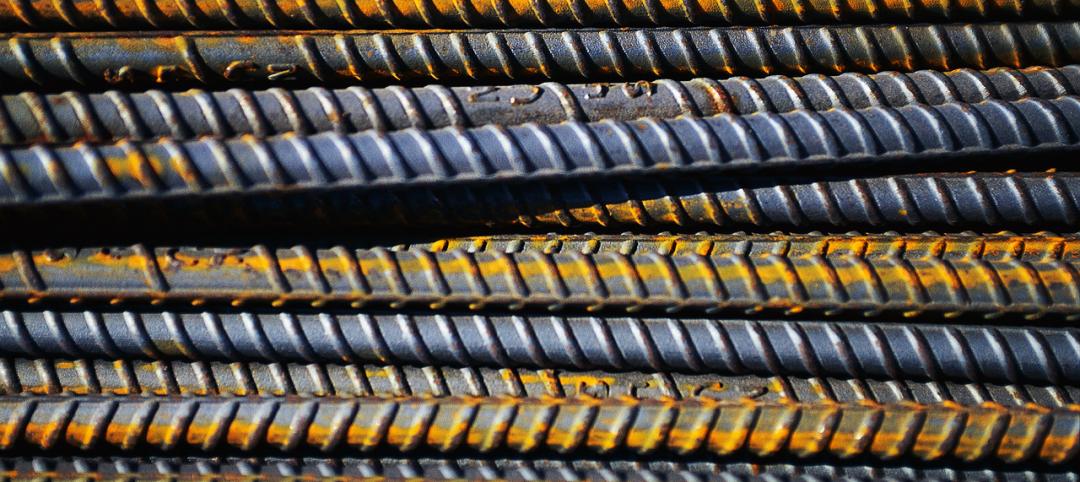

Over 120 workers from LF Driscoll and Balfour Beatty poured 6,540 cubic yards of concrete from 654 concrete trucks over a period of 14 straight hours. The concrete, which is being used to create the foundation of the new building, was poured onto 965 tons of reinforcement steel.

The previous record, according to Curbed Philadelphia, was set in 2016 at the site of the W and Element Hotels. That pour took 24 hours, involved 600 cement trucks, and used 5,850 cubic yards of concrete

The Pavilion is not scheduled to open until 2021.

Related Stories

| Dec 14, 2011

Belfer Research Building tops out in New York

Hundreds of construction trades people celebrate reaching the top of concrete structure for facility that will accelerate treatments and cures at world-renowned institution.

| Dec 12, 2011

CRSI design awards deadline extended to December 31

The final deadline is extended until December 31st, with judging shortly thereafter at the World of Concrete.

| Dec 10, 2011

10 Great Solutions

The editors of Building Design+Construction present 10 “Great Solutions” that highlight innovative technology and products that can be used to address some of the many problems Building Teams face in their day-to-day work. Readers are encouraged to submit entries for Great Solutions; if we use yours, you’ll receive a $25 gift certificate. Look for more Great Solutions in 2012 at: www.bdcnetwork.com/greatsolutions/2012.

| Dec 10, 2011

Energy performance starts at the building envelope

Rainscreen system installed at the west building expansion of the University of Arizona’s Meinel Optical Sciences Center in Tucson, with its folded glass wall and copper-paneled, breathable cladding over precast concrete.

| Dec 6, 2011

Mortenson Construction completes Elk Wind Project in Iowa

By the end of 2011, Mortenson will have built 17 wind projects in the state generating a total of 1894 megawatts of renewable power.

| Dec 2, 2011

What are you waiting for? BD+C's 2012 40 Under 40 nominations are due Friday, Jan. 20

Nominate a colleague, peer, or even yourself. Applications available here.

| Nov 22, 2011

New Green Matters Conference examines emerging issues in concrete and sustainability

High-interest topics will be covered in technical seminars, including infrared reflective coatings for heat island mitigation, innovative uses of concrete to provide cooling and stormwater management, environmental benefits of polished concrete, and advancements in functional resilience of architectural concrete.

| Nov 16, 2011

CRSI recommends return to inch-pound markings

The intention of this resolution is for all new rollings of reinforcing steel products to be marked with inch-pound bar markings no later than January 1st, 2014.

| Nov 8, 2011

Transforming a landmark coastal resort

Originally built in 1973, the building had received several alterations over the years but the progressive deterioration caused by the harsh salt water environment had never been addressed.

| Nov 8, 2011

WEB EXCLUSIVE: Moisture-related failures in agglomerated floor tiles

Agglomerated tiles offer an appealing appearance similar to natural stone at a lower cost. To achieve successful installations, manufacturers should provide design data for moisture-related dimensional changes, specifiers should require in-situ moisture testing similar to those used for other flooring materials, and the industry should develop standards for fabrication and installation of agglomerated tiles.