In the world of architecture and engineering, laboratory buildings are among the most complex buildings to design, plan, and document. Traditional methods rely on the use of photographs, hand drawings, or notes to document not only the building but also the equipment that makes up a laboratory. This makes the process difficult, tedious, time consuming, and even allows for documentation errors.

Currently, the most advanced state-of-the-art technology is combining Light Detection and Ranging (LIDAR) technology with Building Information Modeling (BIM) technology. LIDAR is a remote sensing method that uses light in the form of a pulsed laser to measure ranges to Earth. BIM is workflow process software used to model and optimize projects.

The latest LIDAR technology is available in the current version of hand-held devices that are used for field documentation. These devices come equipped with a very reliable LIDAR scanner, which allows one to easily document and scan in a point cloud all the existing conditions of the building like its space, function, and mechanical, electrical, and plumbing (MEP) needs.

Following the LIDAR scan, advanced software is deployed to transfer the data into a point cloud. This serves as a reliable reference to take measurements, to know where equipment is, and what its MEP needs are. Once in the point cloud, it is then exported into Autodesk ReCap Pro, and later to Autodesk Revit, which are BIM solutions.

Here it is not only inserted into the point cloud to corroborate measurements, locations and needs. It is also with the use of BIM technology and the use of special equipment families, that the foundations for the use of 7D Management of the laboratory equipment and MEP items can be developed into a 7D BIM Model.

A digital twin, which is a digital representation of a physical object or process in a digital version of its environment, can also be developed from this point. Digital twins can help an organization simulate real situations and their outcomes, ultimately allowing it to make better decisions.

LIDAR and BIM technology for building data collection

LIDAR and BIM technology such as Revit allows the existing conditions captured on site to be preserved in the digital model, allowing for measurements, orientation to aspects of the model, etc. without having to be physically on site, and more importantly, to have an orientation as to where each piece of equipment is and what the MEP needs are.

Even for any highly experienced architect or BIM modeler, just using photographs or hand drawings can be overwhelming and very complicated. Using this process, the Revit model serves as a replica of the existing conditions of each space and equipment. During a building expansion, being able to compare existing equipment in the new space is more accurate and easier to understand.

For example, Hampton Roads Sanitation District (HRSD) in Virginia Beach, Va., used LIDAR and BIM technology to develop precise building and equipment data for a planned expansion of its Central Environmental Laboratory.

The process involved meticulously scanning each space relevant to the project. This comprehensive scan aimed to capture every corner accurately. Following the scanning phase, the data was processed, generating a point cloud in ReCap Pro format. With the point cloud, we harnessed the advantages of LIDAR technology such as digitally acquiring existing conditions of the building and equipment, essentially providing a virtual on-site experience with just a click, eliminating the need for physical site visits.

This technology has enabled us to create detailed digital 3D families for every existing piece of equipment and its needs, as well as to capture more accurate existing conditions for the building. In the past, our approach relied solely on on-site measurements and photographs, leading to continuous errors and laborious, time-consuming tasks.

The previous method also necessitated numerous site visits for data verification. The implementation of this advanced technology and streamlined process has not only saved time and money but has also significantly enhanced our efficiency. For instance, all of that work required in the past to digitally model from notes, photographs, existing building plans, etc. has been condensed to the import and refinement of the point cloud data into the modeling environment.

Related Stories

Architects | Aug 5, 2021

Lord Aeck Sargent's post-Katerra future, with LAS President Joe Greco

After three years under the ownership of Katerra, which closed its North American operations last May, the architecture firm Lord Aeck Sargent is re-establishing itself as an independent company, with an eye toward strengthening its eight practices and regional presence in the U.S.

AEC Tech | Jul 14, 2021

Bjarke Ingels Group and UNStudio invest in SpaceForm, a virtual workspace for architects

Squint/Opera developed the platform in 2018.

AEC Tech | Jun 30, 2021

Orro Launches New Integration with Sonos, Providing Seamless In-Wall Control for Sonos Speakers

With the new integration, customers can use the dynamic display on Orro’s smart light switches to control their favorite audio content on their Sonos speakers.

AEC Tech | Jun 9, 2021

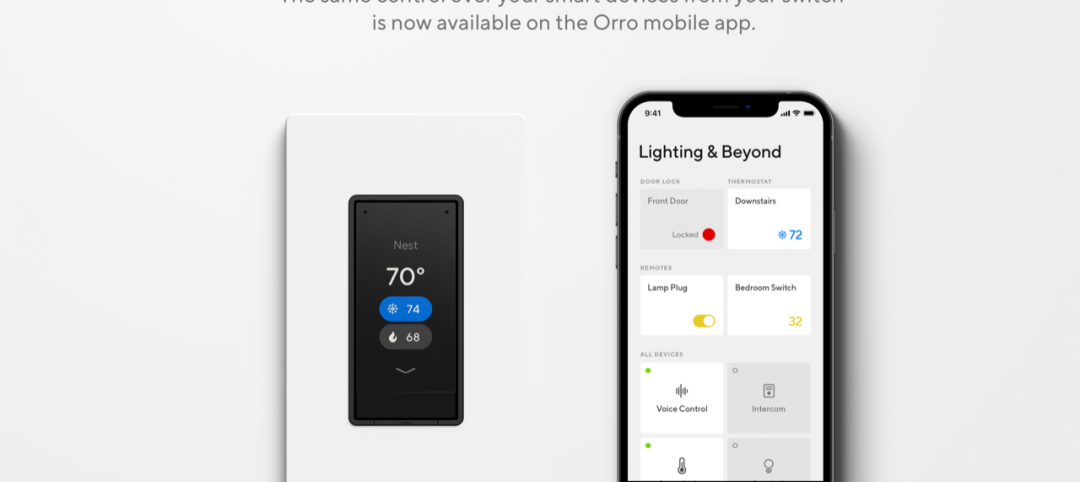

Orro Announces Unified Smart Home App

Orro app now provides control of other smart home devices from leading professional and consumer device manufacturers.

AEC Tech | Jun 8, 2021

FARO Expands Digital Twin Product Suite - Acquires HoloBuilder Inc.

FARO Technologies, a global leader of 3D measurement, imaging, and realization solutions for the 3D Metrology, AEC (Architecture, Engineering & Construction), and Public Safety Analytics markets, today announced the acquisition of HoloBuilder, Inc.

AEC Tech | May 27, 2021

New Work Zone Cam Pro Delivers 33% More Detail for Time-Lapse

Work Zone Cam, a leading provider of professional jobsite construction camera services, premiered its latest camera, which increases image resolution from 18 to 24 megapixels. The additional image detail helps track construction progress more accurately and results in higher resolution time-lapses for construction documentation.

Digital Twin | May 24, 2021

Digital twin’s value propositions for the built environment, explained

Ernst & Young’s white paper makes its cases for the technology’s myriad benefits.

AEC Tech | Apr 15, 2021

3 startups making their mark in 2021

Meet a trio of AEC tech firms that are making advances in the COVID-19 era.

Adaptive Reuse | Apr 15, 2021

The Weekly Show, Apr 15, 2021: The ins and outs of adaptive reuse, and sensors for real-time construction monitoring

This week on The Weekly show, BD+C editors speak with AEC industry leaders from PBDW Architects and Wohlsen Construction about what makes adaptive reuse projects successful, and sensors for real-time monitoring of concrete construction.

AEC Tech | Apr 8, 2021

The Weekly Show, April 8, 2021: SPOT the autonomous robot, and Woods Bagot's in-house 'futurist'

This week on The Weekly show, BD+C editors speak with AEC industry leaders from Procon Consulting, Virginia Tech, and Woods Bagot about SPOT, the autonomous robot for construction progress monitoring applications, and how Woods Bagot's new "futurist" is promoting innovation at the international design firm.