In the world of architecture and engineering, laboratory buildings are among the most complex buildings to design, plan, and document. Traditional methods rely on the use of photographs, hand drawings, or notes to document not only the building but also the equipment that makes up a laboratory. This makes the process difficult, tedious, time consuming, and even allows for documentation errors.

Currently, the most advanced state-of-the-art technology is combining Light Detection and Ranging (LIDAR) technology with Building Information Modeling (BIM) technology. LIDAR is a remote sensing method that uses light in the form of a pulsed laser to measure ranges to Earth. BIM is workflow process software used to model and optimize projects.

The latest LIDAR technology is available in the current version of hand-held devices that are used for field documentation. These devices come equipped with a very reliable LIDAR scanner, which allows one to easily document and scan in a point cloud all the existing conditions of the building like its space, function, and mechanical, electrical, and plumbing (MEP) needs.

Following the LIDAR scan, advanced software is deployed to transfer the data into a point cloud. This serves as a reliable reference to take measurements, to know where equipment is, and what its MEP needs are. Once in the point cloud, it is then exported into Autodesk ReCap Pro, and later to Autodesk Revit, which are BIM solutions.

Here it is not only inserted into the point cloud to corroborate measurements, locations and needs. It is also with the use of BIM technology and the use of special equipment families, that the foundations for the use of 7D Management of the laboratory equipment and MEP items can be developed into a 7D BIM Model.

A digital twin, which is a digital representation of a physical object or process in a digital version of its environment, can also be developed from this point. Digital twins can help an organization simulate real situations and their outcomes, ultimately allowing it to make better decisions.

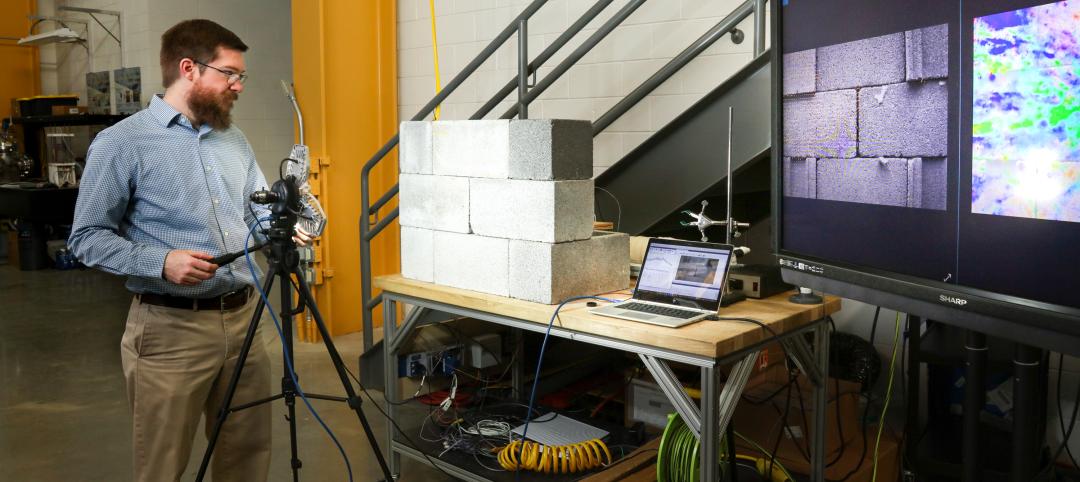

LIDAR and BIM technology for building data collection

LIDAR and BIM technology such as Revit allows the existing conditions captured on site to be preserved in the digital model, allowing for measurements, orientation to aspects of the model, etc. without having to be physically on site, and more importantly, to have an orientation as to where each piece of equipment is and what the MEP needs are.

Even for any highly experienced architect or BIM modeler, just using photographs or hand drawings can be overwhelming and very complicated. Using this process, the Revit model serves as a replica of the existing conditions of each space and equipment. During a building expansion, being able to compare existing equipment in the new space is more accurate and easier to understand.

For example, Hampton Roads Sanitation District (HRSD) in Virginia Beach, Va., used LIDAR and BIM technology to develop precise building and equipment data for a planned expansion of its Central Environmental Laboratory.

The process involved meticulously scanning each space relevant to the project. This comprehensive scan aimed to capture every corner accurately. Following the scanning phase, the data was processed, generating a point cloud in ReCap Pro format. With the point cloud, we harnessed the advantages of LIDAR technology such as digitally acquiring existing conditions of the building and equipment, essentially providing a virtual on-site experience with just a click, eliminating the need for physical site visits.

This technology has enabled us to create detailed digital 3D families for every existing piece of equipment and its needs, as well as to capture more accurate existing conditions for the building. In the past, our approach relied solely on on-site measurements and photographs, leading to continuous errors and laborious, time-consuming tasks.

The previous method also necessitated numerous site visits for data verification. The implementation of this advanced technology and streamlined process has not only saved time and money but has also significantly enhanced our efficiency. For instance, all of that work required in the past to digitally model from notes, photographs, existing building plans, etc. has been condensed to the import and refinement of the point cloud data into the modeling environment.

Related Stories

BIM and Information Technology | Mar 11, 2024

BIM at LOD400: Why Level of Development 400 matters for design and virtual construction

As construction projects grow more complex, producing a building information model at Level of Development 400 (LOD400) can accelerate schedules, increase savings, and reduce risk, writes Stephen E. Blumenbaum, PE, SE, Walter P Moore's Director of Construction Engineering.

AEC Tech | Mar 9, 2024

9 steps for implementing digital transformation in your AEC business

Regardless of a businesses size and type, digital solutions like workflow automation software, AI-based analytics, and integrations can significantly enhance efficiency, productivity, and competitiveness.

AEC Innovators | Feb 28, 2024

How Suffolk Construction identifies ConTech and PropTech startups for investment, adoption

Contractor giant Suffolk Construction has invested in 27 ConTech and PropTech companies since 2019 through its Suffolk Technologies venture capital firm. Parker Mundt, Suffolk Technologies’ Vice President–Platforms, recently spoke with Building Design+Construction about his company’s investment strategy.

AEC Tech | Feb 20, 2024

AI for construction: What kind of tool can artificial intelligence become for AEC teams?

Avoiding the hype and gathering good data are half the battle toward making artificial intelligence tools useful for performing design, operational, and jobsite tasks.

AEC Tech | Feb 20, 2024

ABC releases technology guide for AI in construction

Associated Builders and Contractors has released an artificial intelligence (AI) technology guide for the U.S. construction industry. AI in Construction — What Does It Mean for Our Contractors? outlines definitions, construction use cases, and considerations for the implementation of AI in construction.

AEC Tech | Jan 24, 2024

4 ways AEC firms can benefit from digital transformation

While going digital might seem like a playground solely for industry giants, the truth is that any company can benefit from the power of technology.

Modular Building | Jan 19, 2024

Building with shipping containers not as eco-friendly as it seems

With millions of shipping containers lying empty at ports around the world, it may seem like repurposing them to construct buildings would be a clear environmental winner. The reality of building with shipping containers is complicated, though, and in many cases isn’t a net-positive for the environment, critics charge, according to a report by NPR's Chloe Veltman.

AEC Tech | Jan 8, 2024

What's driving the surge of digital transformation in AEC today?

For centuries, the AEC industry has clung to traditional methods and legacy processes—seated patterns that have bred resistance to change. This has made the adoption of new technologies a slow and hesitant process.

Sustainability | Nov 1, 2023

Researchers create building air leakage detection system using a camera in real time

Researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory have developed a system that uses a camera to detect air leakage from buildings in real time.

Building Owners | Aug 23, 2023

Charles Pankow Foundation releases free project delivery selection tool for building owners, developers, and project teams

Building owners and project teams can use the new Building Owner Assessment Tool (BOAT) to better understand how an owner's decision-making profile impacts outcomes for different project delivery methods.