It seems like a bit of modern day magic. Tap a few keys on your keyboard, perhaps with an accompanying mouse click or two, and then, voila!, one to two days later that new bestseller, necktie, or roll of novelty toilet paper you ordered is at your front door. And here you were thinking Santa Claus wasn’t real.

Okay, so maybe Santa has nothing to do with it, but it can be easy to forget those items you ordered didn’t just materialize out of thin air as if they were transported from the bridge of the Starship Enterprise. Sure, you clicked "Order" on Amazon, Target, or Walmart’s website, but what happens next? More likely than not, after your order information was received, the product had to be retrieved from a big box warehouse.

A big box warehouse is a facility that is over 300,000-sf with 28-foot ceilings or higher. These warehouses are commonly used among retailers to store products awaiting purchase by online consumers. As more and more sales start to take place online, retailers are beginning to adjust their distribution networks accordingly, The Wall Street Journal reports.

In 2015, 61 million sf of these big box warehouses were constructed in North America. That marks an increase of almost 6 times in a four-year span, according to Colliers International Group. There isn’t expected to be any slowdown in 2016, either, as an additional 74 million sf are projected to be completed by the end of the year.

Home Depot, Target Corp., and Wal-Mart Stores Inc. all felt the need, due to the uptick in online shopping, to build huge fulfillment centers meant to store, pack, and ship items to online customers.

These large warehouses aren’t necessarily out in the middle of nowhere, either. As one- and two-day deliveries become the standard for much of the country, building close to large population centers, ports, and rail lines is becoming imperative. There is 16.2 million sf of big box construction occurring in the Los Angeles area alone, and Eastern Pennsylvania and New Jersey aren’t far behind, with 13.3 million sf under construction.

Additionally, there is a trend toward building slightly smaller warehouses, in the 200,000-sf range, in high population urban zones to increase the speed at which online customers can receive their purchases even further. Some Amazon customers are able to get their deliveries a mere one to two hours after making the purchase.

These big box warehouses and their smaller-sized counterparts aren’t acting as a snake eating its own tail, either. Instead, they are working in tandem as a “two-pronged approach,” according to Dwight Hotchkiss, National Director of U.S. Industrial Services for Colliers. The smaller warehouses are able to satisfy one-hour delivery to urban markets while the big box warehouses handle one-day and same-day e-commerce.

While they might not be as rare (and becoming less so every day) or whimsical as Santa’s workshop, these big box warehouses are basically the real world equivalent. And as more of them are created close to urban centers, you won’t have to wait until the holidays to receive your packages. At the pace these big box warehouses are being created, you might not even have to wait until tomorrow.

Related Stories

| Jan 11, 2014

Getting to net-zero energy with brick masonry construction [AIA course]

When targeting net-zero energy performance, AEC professionals are advised to tackle energy demand first. This AIA course covers brick masonry's role in reducing energy consumption in buildings.

| Jan 7, 2014

Concrete solutions: 9 innovations for a construction essential

BD+C editors offer a roundup of new products and case studies that represent the latest breakthroughs in concrete technology.

| Jan 6, 2014

What is value engineering?

If you had to define value engineering in a single word, you might boil it down to "efficiency." That would be one word, but it wouldn’t be accurate.

| Dec 20, 2013

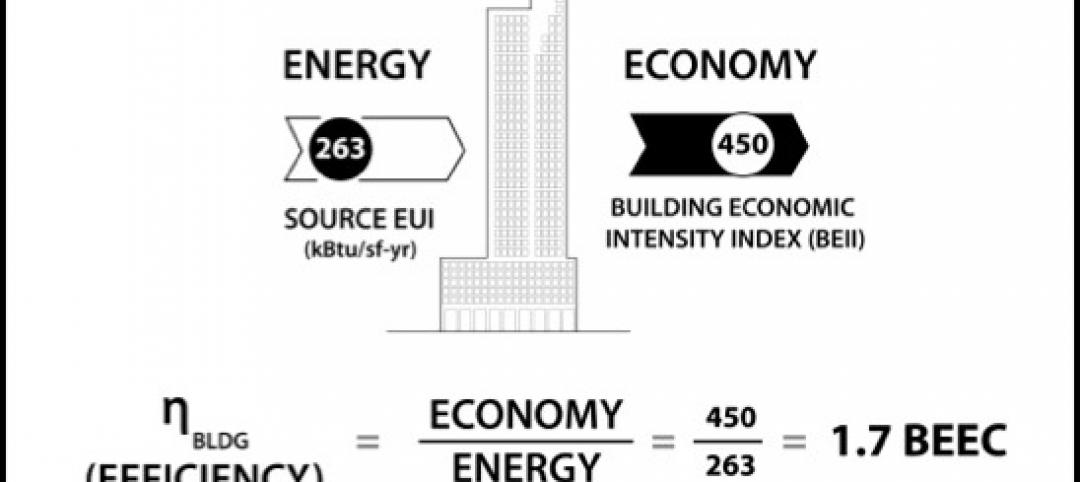

Can energy hogs still be considered efficient buildings? Yes, say engineers at Buro Happold

A new tool from the engineering firm Buro Happold takes into account both energy and economic performance of buildings for a true measure of efficiency.

| Dec 17, 2013

Kahn appoints Alan Cobb President and CEO

Cobb is the tenth president in the firm’s 118-year history. As President, Cobb is responsible for ensuring that all of the firm’s client issues are effectively address and that overall project team performance meets or exceeds client expectations for each and job the firm undertakes.

| Dec 13, 2013

Safe and sound: 10 solutions for fire and life safety

From a dual fire-CO detector to an aspiration-sensing fire alarm, BD+C editors present a roundup of new fire and life safety products and technologies.

| Dec 10, 2013

16 great solutions for architects, engineers, and contractors

From a crowd-funded smart shovel to a why-didn’t-someone-do-this-sooner scheme for managing traffic in public restrooms, these ideas are noteworthy for creative problem-solving. Here are some of the most intriguing innovations the BD+C community has brought to our attention this year.

| Dec 9, 2013

Bethlehem, Pa., receives preservation award for Bethlehem Steel building renovation

Bethlehem, Pa., is a recipient of a 2013 award by Preservation Pennsylvania for a renovation of the oldest building on the former Bethlehem Steel Corp. site.

| Nov 27, 2013

Exclusive survey: Revenues increased at nearly half of AEC firms in 2013

Forty-six percent of the respondents to an exclusive BD+C survey of AEC professionals reported that revenues had increased this year compared to 2012, with another 24.2% saying cash flow had stayed the same.

| Nov 27, 2013

Wonder walls: 13 choices for the building envelope

BD+C editors present a roundup of the latest technologies and applications in exterior wall systems, from a tapered metal wall installation in Oklahoma to a textured precast concrete solution in North Carolina.