It seems like a bit of modern day magic. Tap a few keys on your keyboard, perhaps with an accompanying mouse click or two, and then, voila!, one to two days later that new bestseller, necktie, or roll of novelty toilet paper you ordered is at your front door. And here you were thinking Santa Claus wasn’t real.

Okay, so maybe Santa has nothing to do with it, but it can be easy to forget those items you ordered didn’t just materialize out of thin air as if they were transported from the bridge of the Starship Enterprise. Sure, you clicked "Order" on Amazon, Target, or Walmart’s website, but what happens next? More likely than not, after your order information was received, the product had to be retrieved from a big box warehouse.

A big box warehouse is a facility that is over 300,000-sf with 28-foot ceilings or higher. These warehouses are commonly used among retailers to store products awaiting purchase by online consumers. As more and more sales start to take place online, retailers are beginning to adjust their distribution networks accordingly, The Wall Street Journal reports.

In 2015, 61 million sf of these big box warehouses were constructed in North America. That marks an increase of almost 6 times in a four-year span, according to Colliers International Group. There isn’t expected to be any slowdown in 2016, either, as an additional 74 million sf are projected to be completed by the end of the year.

Home Depot, Target Corp., and Wal-Mart Stores Inc. all felt the need, due to the uptick in online shopping, to build huge fulfillment centers meant to store, pack, and ship items to online customers.

These large warehouses aren’t necessarily out in the middle of nowhere, either. As one- and two-day deliveries become the standard for much of the country, building close to large population centers, ports, and rail lines is becoming imperative. There is 16.2 million sf of big box construction occurring in the Los Angeles area alone, and Eastern Pennsylvania and New Jersey aren’t far behind, with 13.3 million sf under construction.

Additionally, there is a trend toward building slightly smaller warehouses, in the 200,000-sf range, in high population urban zones to increase the speed at which online customers can receive their purchases even further. Some Amazon customers are able to get their deliveries a mere one to two hours after making the purchase.

These big box warehouses and their smaller-sized counterparts aren’t acting as a snake eating its own tail, either. Instead, they are working in tandem as a “two-pronged approach,” according to Dwight Hotchkiss, National Director of U.S. Industrial Services for Colliers. The smaller warehouses are able to satisfy one-hour delivery to urban markets while the big box warehouses handle one-day and same-day e-commerce.

While they might not be as rare (and becoming less so every day) or whimsical as Santa’s workshop, these big box warehouses are basically the real world equivalent. And as more of them are created close to urban centers, you won’t have to wait until the holidays to receive your packages. At the pace these big box warehouses are being created, you might not even have to wait until tomorrow.

Related Stories

| Jun 18, 2014

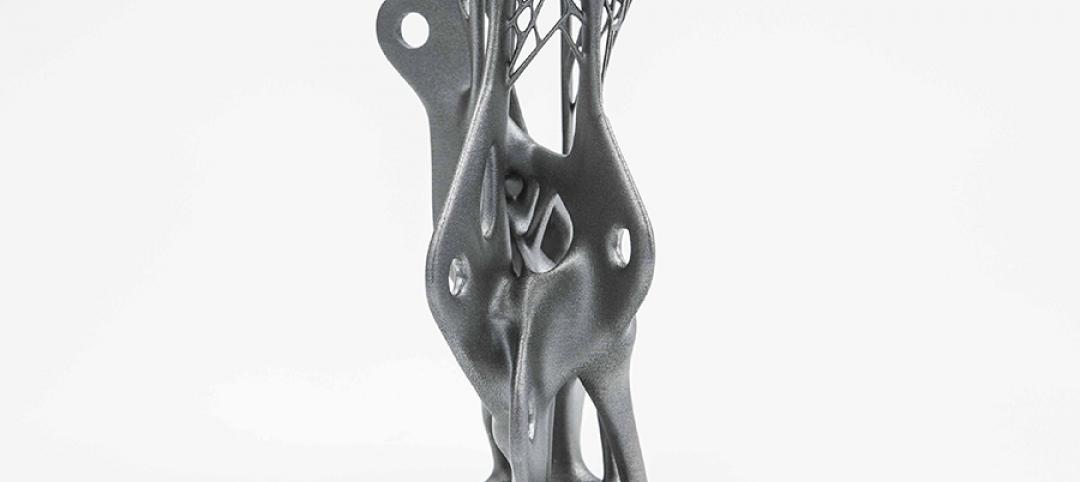

Arup uses 3D printing to fabricate one-of-a-kind structural steel components

The firm's research shows that 3D printing has the potential to reduce costs, cut waste, and slash the carbon footprint of the construction sector.

| Jun 12, 2014

Austrian university develops 'inflatable' concrete dome method

Constructing a concrete dome is a costly process, but this may change soon. A team from the Vienna University of Technology has developed a method that allows concrete domes to form with the use of air and steel cables instead of expensive, timber supporting structures.

| May 29, 2014

7 cost-effective ways to make U.S. infrastructure more resilient

Moving critical elements to higher ground and designing for longer lifespans are just some of the ways cities and governments can make infrastructure more resilient to natural disasters and climate change, writes Richard Cavallaro, President of Skanska USA Civil.

| May 22, 2014

Facebook, Telus push the limits of energy efficiency with new data centers

Building Teams are employing a range of creative solutions—from evaporative cooling to novel hot/cold-aisle configurations to heat recovery schemes—in an effort to slash energy and water demand.

| May 22, 2014

Big Data meets data centers – What the coming DCIM boom means to owners and Building Teams

The demand for sophisticated facility monitoring solutions has spurred a new market segment—data center infrastructure management (DCIM)—that is likely to impact the way data center projects are planned, designed, built, and operated.

| May 20, 2014

Kinetic Architecture: New book explores innovations in active façades

The book, co-authored by Arup's Russell Fortmeyer, illustrates the various ways architects, consultants, and engineers approach energy and comfort by manipulating air, water, and light through the layers of passive and active building envelope systems.

| May 19, 2014

What can architects learn from nature’s 3.8 billion years of experience?

In a new report, HOK and Biomimicry 3.8 partnered to study how lessons from the temperate broadleaf forest biome, which houses many of the world’s largest population centers, can inform the design of the built environment.

| May 13, 2014

19 industry groups team to promote resilient planning and building materials

The industry associations, with more than 700,000 members generating almost $1 trillion in GDP, have issued a joint statement on resilience, pushing design and building solutions for disaster mitigation.

| May 11, 2014

Final call for entries: 2014 Giants 300 survey

BD+C's 2014 Giants 300 survey forms are due Wednesday, May 21. Survey results will be published in our July 2014 issue. The annual Giants 300 Report ranks the top AEC firms in commercial construction, by revenue.

| Apr 29, 2014

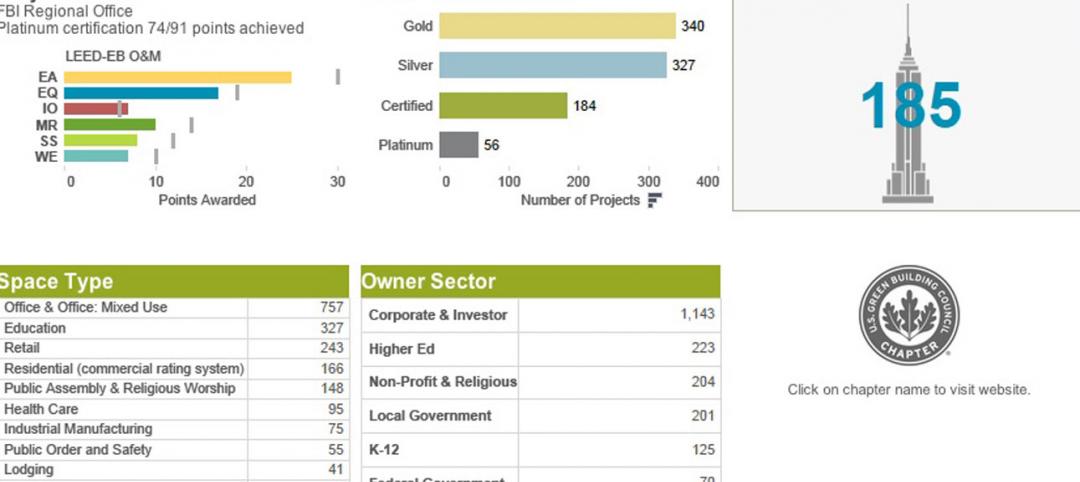

USGBC launches real-time green building data dashboard

The online data visualization resource highlights green building data for each state and Washington, D.C.