|

|

Workers inspect a rooftop PV installation. Improper handling, storage, or installation of the PV panels can cause damage to the roof. |

The popularity of rooftop photovoltaic (PV) panels has exploded during the past decade as Building Teams look to maximize building energy efficiency, implement renewable energy measures, and achieve green building certification for their projects.

However, installing rooftop PV systems—rack-mounted, roof-bearing, or fully integrated systems—requires careful consideration to avoid damaging the roof system. Improper handling, storage, or installation of the PV panels can cause damage to the roof, which can lead to moisture intrusion, wind uplift problems, and even structural damage. In addition, rooftop PV systems should be designed with future maintenance, roof repairs, and fire-suppression efforts in mind.

BD+C asked a pair of top-notch roofing experts to identify the most critical design, construction, and installation considerations. They offer the following tips:

|

|

Photovoltaic arrays should be confi gured to allow access for future maintenance, roof repairs, and fire-suppression efforts. |

1. Verify the fire rating of your rooftop photovoltaic system.Most rooftop PV systems qualify for a Class C fire rating, while most of the roof coverings over which these systems are installed are fire rated Class A or B, says Philip D. Dregger, PE, RRC, principal with roof and waterproofing consultant Technical Roof Services Inc., Concord, Calif.

Dregger says the fire rating, especially spread of flame, is critical, especially for roof-bearing and rack-mounted systems. For instance, Building Teams may need to take steps like incorporating half-inch gypsum board into the assembly to obtain the proper fire rating.

For sloped roofs, Dregger says it is especially important to confirm that the required fire classification is available at the slope required. “For instance, standing-seam metal roofs routinely qualify as Class A fire-resistant on unlimited slopes, whereas the same standing-seam metal roofs covered with thin-film, flexible PV panels have significant slope restrictions,” he says.

2. Flashing detail is critical for maintaining the warranty. Flashing detail work must be performed by a contractor approved by the roof membrane manufacturer, says Mike Ennis, technical director of the Single Ply Roofing Industry (SPRI), Waltham, Mass., which recently convened a task force to identify key rooftop PV installation issues. “It's not so much a difference in the details as it is that the details are properly completed,” says Ennis.

Building owners must get such permission in advance from the roofing manufacturer or the warranty may be voided. The main concern, says Ennis, is keeping a record of alterations to the roof system. “For example, if a manufacturer gets a leak call immediately after an alternation is completed, they know where to start looking for the leak,” he says.

3. PV systems must be properly marked. Marking is needed to provide emergency responders with appropriate warning and guidance with respect to working around and isolating the solar electric system. Proper marking helps responders identify energized electrical lines that connect the solar modules to the inverter, according to the California Department of Forestry and Fire Protection's (CDFFP) Solar Photovoltaic Installation Guideline (www.osfm.fire.ca.gov/pdf/reports/solarphotovoltaicguideline.pdf).

Materials used for marking must be weather resistant and should be placed adjacent to the main service disconnect in a location clearly visible from the location where the lever is operated.

4. Make sure to protect the roof system while handling PV panels. Damage to roof systems, especially single-ply membranes, often occurs during the handling of the PV panels. SPRI's Ennis offers four tips for avoiding roof system damage while moving and storing PVs:

-

Store boxed PV units over joists to avoid deflecting the metal deck.

-

If boxed units are palletized, place a cushion layer of plywood between the pallet and the roof surface.

-

Do not point-load the roof surface by placing the corner of a hard panel directly on the surface.

-

Use moving equipment fitted with pneumatic tires to transport equipment and materials over the finished roof surface.

5. In retrofit projects, consider roof life before installing PVs. Due to potentially high costs associated with temporarily disconnecting and moving PV panels to execute roof repairs, Building Teams should assess the remaining life of the existing roof covering as part of a PV project, says Dregger.

He says serious consideration should be given to replacing the existing roof covering as part of a PV project. At the very least, says Dregger, you should investigate and repair roof leaks and perform any preventive maintenance work, even if it is not scheduled to be performed for a couple of years.

6. Pay close attention to the location of direct current (DC) conductors. Conduit, wiring systems, and raceways for photovoltaic circuits should be located as close as possible to the ridge or hip or valley and from the hip or valley as directly as possible to an outside wall to reduce trip hazards and maximize ventilation opportunities, according to the CDFFP's installation guidelines.

DC combiner boxes should be located such that conduit runs are minimized in the pathways between arrays. To limit the hazard of cutting live conduit in venting operations, DC wiring should be run in metallic conduit or raceways when located within enclosed spaces in a building and should be run (to the maximum extent possible) along the bottom of load-bearing members.

7. Provide for fall protection in certain cases. In retrofit projects, if the PV modules direct foot traffic to within six feet of unprotected roof edges or roof openings, fall protection provisions, such as guardrails and roof hatches, are a must, says Dregger.

8. Configure PV arrays to allow access for future maintenance, roof repairs, and fire-suppression efforts. CDFFP's installation guidelines recommend a minimum of six feet of clearance along the perimeter of the roof and at least four feet around roof access hatches and skylights. Also, pathways should be provided along the centerline of both axes of the roof. Locate these pathways over structural members.

9. Make sure integrated PV panels can handle high winds. For semi-rigid PV panels adhered over mechanically attached single-ply roofs, make sure that the PV panels can accommodate billowing of the singly-ply membrane during high-wind conditions without incurring damage, such as cracking, splitting, or rupture. Dregger recommends installing air retarders and supplemental membrane fasteners around each PV panel to help avoid damage.

Related Stories

MFPRO+ Research | Feb 28, 2024

New download: BD+C's 2023 Multifamily Amenities report

New research from Building Design+Construction and Multifamily Pro+ highlights the 127 top amenities that developers, property owners, architects, contractors, and builders are providing in today’s apartment, condominium, student housing, and senior living communities.

AEC Tech | Feb 28, 2024

How to harness LIDAR and BIM technology for precise building data, equipment needs

By following the Scan to Point Cloud + Point Cloud to BIM process, organizations can leverage the power of LIDAR and BIM technology at the same time. This optimizes the documentation of existing building conditions, functions, and equipment needs as a current condition and as a starting point for future physical plant expansion projects.

Data Centers | Feb 28, 2024

What’s next for data center design in 2024

Nuclear power, direct-to-chip liquid cooling, and data centers as learning destinations are among the emerging design trends in the data center sector, according to Scott Hays, Sector Leader, Sustainable Design, with HED.

Windows and Doors | Feb 28, 2024

DOE launches $2 million prize to advance cost-effective, energy-efficient commercial windows

The U.S. Department of Energy launched the American-Made Building Envelope Innovation Prize—Secondary Glazing Systems. The program will offer up to $2 million to encourage production of high-performance, cost-effective commercial windows.

AEC Innovators | Feb 28, 2024

How Suffolk Construction identifies ConTech and PropTech startups for investment, adoption

Contractor giant Suffolk Construction has invested in 27 ConTech and PropTech companies since 2019 through its Suffolk Technologies venture capital firm. Parker Mundt, Suffolk Technologies’ Vice President–Platforms, recently spoke with Building Design+Construction about his company’s investment strategy.

Performing Arts Centers | Feb 27, 2024

Frank Gehry-designed expansion of the Colburn School performing arts center set to break ground

In April, the Colburn School, an institute for music and dance education and performance, will break ground on a 100,000-sf expansion designed by architect Frank Gehry. Located in downtown Los Angeles, the performing arts center will join the neighboring Walt Disney Concert Hall and The Grand by Gehry, forming the largest concentration of Gehry-designed buildings in the world.

Construction Costs | Feb 27, 2024

Experts see construction material prices stabilizing in 2024

Gordian’s Q1 2024 Quarterly Construction Cost Insights Report brings good news: Although there are some materials whose prices have continued to show volatility, costs at a macro level are returning to a level of stability, suggesting predictable historical price escalation factors.

Construction Costs | Feb 22, 2024

K-12 school construction costs for 2024

Data from Gordian breaks down the average cost per square foot for four different types of K-12 school buildings (elementary schools, junior high schools, high schools, and vocational schools) across 10 U.S. cities.

MFPRO+ Special Reports | Feb 22, 2024

Crystal Lagoons: A deep dive into real estate's most extreme guest amenity

These year-round, manmade, crystal clear blue lagoons offer a groundbreaking technology with immense potential to redefine the concept of water amenities. However, navigating regulatory challenges and ensuring long-term sustainability are crucial to success with Crystal Lagoons.

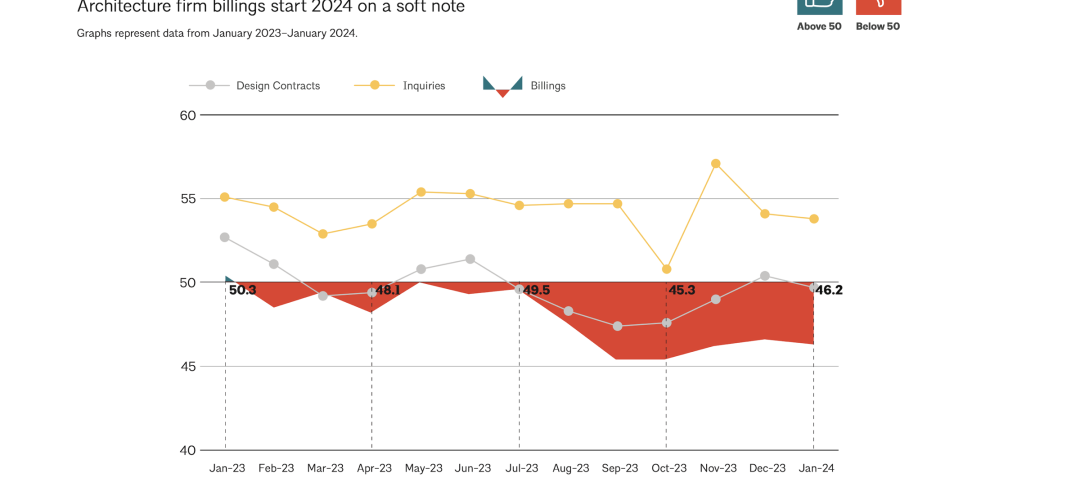

Architects | Feb 21, 2024

Architecture Billings Index remains in 'declining billings' state in January 2024

Architecture firm billings remained soft entering into 2024, with an AIA/Deltek Architecture Billings Index (ABI) score of 46.2 in January. Any score below 50.0 indicates decreasing business conditions.