If you think you've seen it all when it comes to concrete construction, then you haven't sat down with Blaine Brownell.

The architect-turned-blogger-turned-author has become the industry's foremost expert in everything that is unconventional and provocative in the building products field. For the past eight years, this LEED Accredited Professional, BD+C “40 Under 40” winner, and visiting professor at the University of Michigan's Taubman College of Architecture and Urban Planning has made it a priority to track down the newest building products from around the world and report on them in a weekly online newsletter and in two books: Transmaterial (2006) and the newly released Transmaterial 2 (2008), both from Princeton Architectural Press.

I had a chance to pull up a chair and chat with Brownell about some of the most innovative concrete technologies he's come across recently. Here are eight products that are sure to rock your next concrete project:

Translucent fabric creates see-through concrete

Translucent concrete is not exactly new, but HeidelbergCement's approach to transmitting light through concrete is an industry first. Instead of using acrylic rods or optical fibers, Luccon features translucent fabric that is cast layer by layer into fine-grained concrete, allowing light, shadows, and even colors to project through the concrete with negligible degradation. Because the fabric fibers are small in diameter and the proportion of fabric to concrete is relatively low, Luccon delivers the same strength and durability as conventional concrete.

Contents: Concrete, translucent fabric

Applications: Exterior or interior light-transmitting walls, shading devices, illuminated paving, light fixtures, signage

Manufacturer: HeidelbergCement AG

www.heidelbergcement.com

ALSO SEE: 5 things you should know about decorative concrete

Custom concrete patterned surfaces

A Finnish company has developed a patented method for creating patterned concrete surfaces that involves the precise application of a surface retarder to the exterior of a concrete formliner. The surface pattern is the result of the contrast between the smooth face and the exposed fine aggregate in the concrete. This approach allows precast concrete manufacturers to produce highly detailed concrete elements, panels, and slabs with a variety of select patterns, as well as virtually any custom design.

Contents: Concrete, surface-retarder membrane

Applications: Concrete façades, architectural panels, partitions, garden walls, slabs

Manufacturer: Graphic Concrete Ltd.

www.graphicconcrete.com

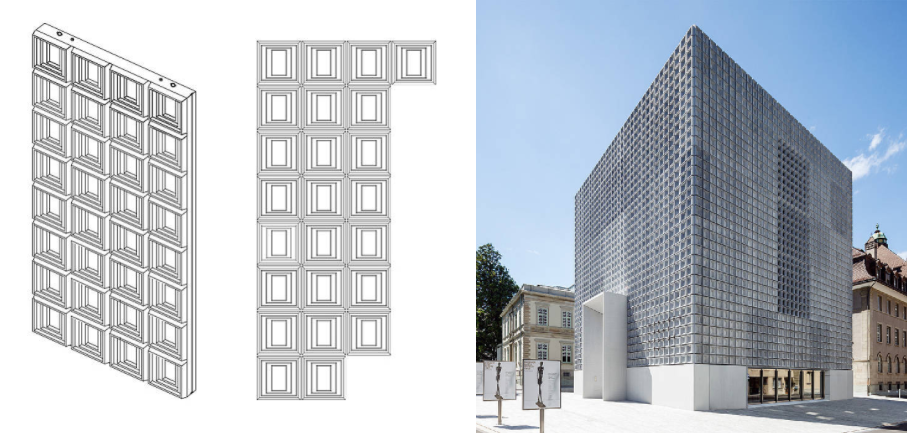

Lightweight concrete

Architectural cladding panels made with CarbonCast carbon-fiber grid reinforcing can weigh up to 66% less than convention precast panels. That's because carbon-fiber reinforcing resists corrosion and therefore requires less concrete cover. These thinner, lighter concrete panels can also be integrated with insulation, increasing the R-value of wall systems. When used in the flanges of pre-topped double tees, CarbonCast can reduce weight by 15% and eliminate the need for sealers and sacrificial barrier coatings.

Contents: Precast concrete, carbon fiber

Applications: Load-bearing and non-load-bearing exterior walls, slabs

Manufacturer: Altus Precast

www.altusprecast.com

Turn up the heat and this concrete will tell you the time

A trio of UK-based product designers has developed a method for incorporating dynamic patterns, numbers, and text into concrete surfaces. Chris Glaister, Afshin Mehin, and Tomas Rosén have figured out that by incorporating thermochromatic pigment and wire heating technology into a standard concrete mix, the color of concrete can be changed. With the use of microprocessor control devices, the color-changing pattern can be precisely manipulated to form complex patterns and even information displays, such as dot-matrix clocks. While Chronos Chromos Concrete is not yet commercially available, the material is being used in several projects, including a 40x78-inch information display in the entrance hall of a new building in London.

Contents: Cement, limestone aggregate, thermochromatic pigment, glass fiber

Applications: Large-scale architectural installations, sealed structural information displays such as clocks and dot-matrix displays

Manufacturer: Chromastone UK

www.chromastone.com

Concrete bends, but won't break

Scientists at the University of Michigan have developed a new type of fiber-reinforced “bendable” concrete that looks like regular concrete but is 500 times more resistant to cracking and 40% lighter in weight. The secret is in the composition, which incorporates silica sand just 100 microns in diameter and tiny polyvinyl alcohol fibers covered with a slick coating. When overloaded, the lubricated fibers begin to slip instead of fracturing. The result is a concrete that bends but will not break. Ideal for structures in high seismic regions, Engineered Cement Composites has been applied in several bridge projects, as well as in two high-rise buildings in Tokyo—Roppongi Pacific Tower and Nabeaure Yokohama Tower.

Contents: Cement, silica sand, polyvinyl alcohol fibers

Applications: Structural members for bridges and buildings, especially those located in high seismic regions

Manufacturer: University of Michigan, College of Engineering, Victor C. Li, PhD

http://www.umich.edu/~acemrl/

Add texture to exposed concrete surfaces in a snap

While fabrication of textured exposed concrete surfaces using elastic formliners has been practiced worldwide for more than 35 years, Reckli Formliners offers a significant improvement to the traditional approach. Made from elastic polyurethane, the formliners allow the release of the formliner from precast or cast-in-place concrete without damage to either the concrete surface or the formliner itself. Each formliner is good for between 50 and 100 reuses, making large-scale decorative concrete installations a snap.

Contents: Polyurethane elastomers

Applications: Precast and cast-in-place concrete

Manufacturer: Reckli-Chemiewerkstoff GmbH

www.reckli.de

The world's heaviest wallpaper

At first glance, walls constructed with Walled Paper precast concrete may appear to be covered with decorative paper, but the complex, ornate patterns are actually cast into the surface of the concrete panel. UK-based Concrete Blond can cast more than 50 standard patterns and virtually any custom design into architectural precast panels for interior and exterior cladding, flooring, and surface applications. The patterns can be cast with a textural depth of 1/64 to 3/16 inch on to three types of concrete: Brutalist gray, Victoriana black, and Portland white.

Contents: Concrete

Applications: Wall cladding, flooring, surfaces

Manufacturer: Concrete Blond

www.concrete-blond.com

Don't forget to water your concrete

Developed by Dutch designers Frederik Molenschot and Susanne Happle, Solid Poetry is a concrete tile that reveals a pattern when wet. The detailed patterns are created by carefully applying surface treatment to the finished concrete surface that darkens when exposed to water or humid air. Solid Poetry is ideal for floors, walls, and surfaces in environments that encounter frequent humidity changes, such as poolsides, gardens, bathrooms, and saunas.

Contents: Concrete, surface treatment

Applications: Floors, walls, and surfaces in humid/wet environments

Manufacturer: Studio Frederik Molenschot and Susanne Happle

www.frederikmolenschot.nl

For more products, visit http://transstudio.com.

Related Stories

| Dec 16, 2011

Stalco Construction converts Babylon, N.Y. Town Hall into history museum

The project converted the landmark structure listed on the National Register of Historic Places into the Town of Babylon History Museum at Old Town Hall.

| Dec 14, 2011

Belfer Research Building tops out in New York

Hundreds of construction trades people celebrate reaching the top of concrete structure for facility that will accelerate treatments and cures at world-renowned institution.

| Dec 12, 2011

CRSI design awards deadline extended to December 31

The final deadline is extended until December 31st, with judging shortly thereafter at the World of Concrete.

| Dec 10, 2011

10 Great Solutions

The editors of Building Design+Construction present 10 “Great Solutions” that highlight innovative technology and products that can be used to address some of the many problems Building Teams face in their day-to-day work. Readers are encouraged to submit entries for Great Solutions; if we use yours, you’ll receive a $25 gift certificate. Look for more Great Solutions in 2012 at: www.bdcnetwork.com/greatsolutions/2012.

| Dec 10, 2011

Energy performance starts at the building envelope

Rainscreen system installed at the west building expansion of the University of Arizona’s Meinel Optical Sciences Center in Tucson, with its folded glass wall and copper-paneled, breathable cladding over precast concrete.

| Dec 6, 2011

Mortenson Construction completes Elk Wind Project in Iowa

By the end of 2011, Mortenson will have built 17 wind projects in the state generating a total of 1894 megawatts of renewable power.

| Dec 2, 2011

What are you waiting for? BD+C's 2012 40 Under 40 nominations are due Friday, Jan. 20

Nominate a colleague, peer, or even yourself. Applications available here.

| Nov 22, 2011

New Green Matters Conference examines emerging issues in concrete and sustainability

High-interest topics will be covered in technical seminars, including infrared reflective coatings for heat island mitigation, innovative uses of concrete to provide cooling and stormwater management, environmental benefits of polished concrete, and advancements in functional resilience of architectural concrete.

| Nov 16, 2011

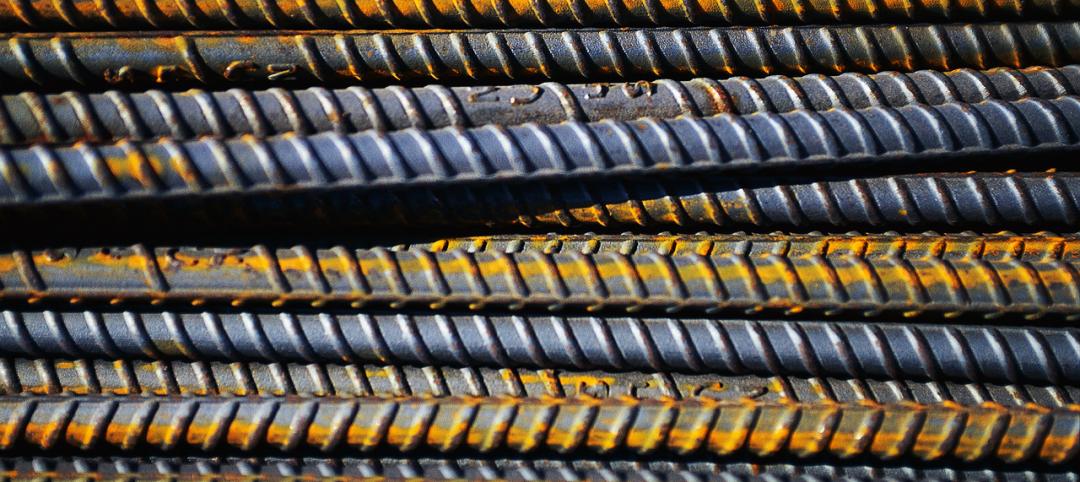

CRSI recommends return to inch-pound markings

The intention of this resolution is for all new rollings of reinforcing steel products to be marked with inch-pound bar markings no later than January 1st, 2014.

| Nov 8, 2011

Transforming a landmark coastal resort

Originally built in 1973, the building had received several alterations over the years but the progressive deterioration caused by the harsh salt water environment had never been addressed.