As experienced designers, contractors, and owners know, most paint and coating problems are correctable, but some are especially stubborn to address. The following is a partial compendium of typical failure modes and methods for addressing the problem, as provided by paint and coatings manufacturer Benjamin Moore & Co. (www.benjaminmoore.com):

1. Surface imperfections.

There are many types of imperfections that can be visible on painted or sealed surfaces. Alligatoring occurs when the paint film takes on the appearance of alligator hide. (A similar problem is known as wrinkling, which appears as a rough creased or crinkled pattern.) Alligatoring usually occurs when a topcoat is applied before an undercoat is dry, or if an alky enamel or other hard, rigid coating is applied over a latex primer or another more flexible finish layer. Some oil-based coats will lose elasticity as they age, causing this familiar cracking pattern.

2. Blistering.

Blistering (or bubbling) is caused by a localized loss of adhesion and lifting of the paint film from the underlying surface, sometimes when solvent gas expands on sunny façades. Blistering tends to occur in fresh coats of paint.

Both problems require removing as much paint as possible and repainting. However, blistering can immediately reappear if the problem is caused by moisture; to mitigate this problem, the contractor should repair loose caulk and retrofit drainage and drying details, if possible. Installing vents or exhaust fans can also reduce moisture by evaporation before it wets enclosure materials.

For alligatoring, most paint contractors will recommend completely remove the existing oil paint by using a heat gun, scraping, and sanding. After priming the reworked surface with a high-quality latex or oil-based primer, the area can then be recoated with exterior latex or similar paint.

3. Flaking and chalking.

In some cases, a painted or coated surface will exhibit a loose powder or flaking surface. These problems are caused by decomposing paint and are different from efflorescence or mottling, which display white, crusty mineral salt deposits that have leached from mortar, concrete, or masonry surfaces behind the paint. A similar problem known as frosting is often seen on dark paints and coatings; in this case, a white discolored substance appears on the surface, similar to salt staining.

Chalking paint may be washed by rain and cause patterns, or it may wash across other surfaces, an effect called chalk rundown.

4. Miscoloring and staining.

Other sources of miscoloration on exterior and interior surfaces include nailheads and other penetrations that leach a rust-colored stain onto a surface, which often trails down from the location of the hardware. Mildew appears as black, gray, or brown spots or areas on the paint film or caulk bead.

5. Surfactant leaching.

Another source of undesired color change is surfactant leaching, in which concentrated, water-soluble ingredients in latexes seep to the paint surface, often creating a brownish blotchy or shiny appearance. Tannin staining can also be a brownish or tan discoloration on the paint surface, caused by wood tannins that leach through the paint film.

When applied properly onto suitably prepared substrates, architectural coatings will rarely exhibit these kinds of failures. Even better, when integrated into a thoughtful sustainability program, paints and coatings can be a partner in effective building designs that promote improvements to project economics and social considerations as well as protecting the environment.

Related Stories

Products and Materials | Jan 31, 2024

Top building products for January 2024

BD+C Editors break down January's top 15 building products, from SloanStone Quartz Molded Sinks to InvisiWrap SA housewrap.

Sponsored | BD+C University Course | Jan 17, 2024

Waterproofing deep foundations for new construction

This continuing education course, by Walter P Moore's Amos Chan, P.E., BECxP, CxA+BE, covers design considerations for below-grade waterproofing for new construction, the types of below-grade systems available, and specific concerns associated with waterproofing deep foundations.

Sponsored | Performing Arts Centers | Jan 17, 2024

Performance-based facilities for performing arts boost the bottom line

A look at design trends for “budget-wise” performing arts facilities reveals ways in which well-planned and well-built facilities help performers and audiences get the most out of the arts. This continuing education course is worth 1.0 AIA learning unit.

Concrete | Jan 12, 2024

Sustainable concrete reduces carbon emissions by at least 30%

Designed by Holcim, a building materials supplier, ECOPact offers a sustainable concrete alternative that not only meets, but exceeds the properties of standard concrete.

Mass Timber | Jan 2, 2024

5 ways mass timber will reshape the design of life sciences facilities

Here are five reasons why it has become increasingly evident that mass timber is ready to shape the future of laboratory spaces.

75 Top Building Products | Dec 13, 2023

75 top building products for 2023

From a bladeless rooftop wind energy system, to a troffer light fixture with built-in continuous visible light disinfection, innovation is plentiful in Building Design+Construction's annual 75 Top Products report.

Products and Materials | Oct 31, 2023

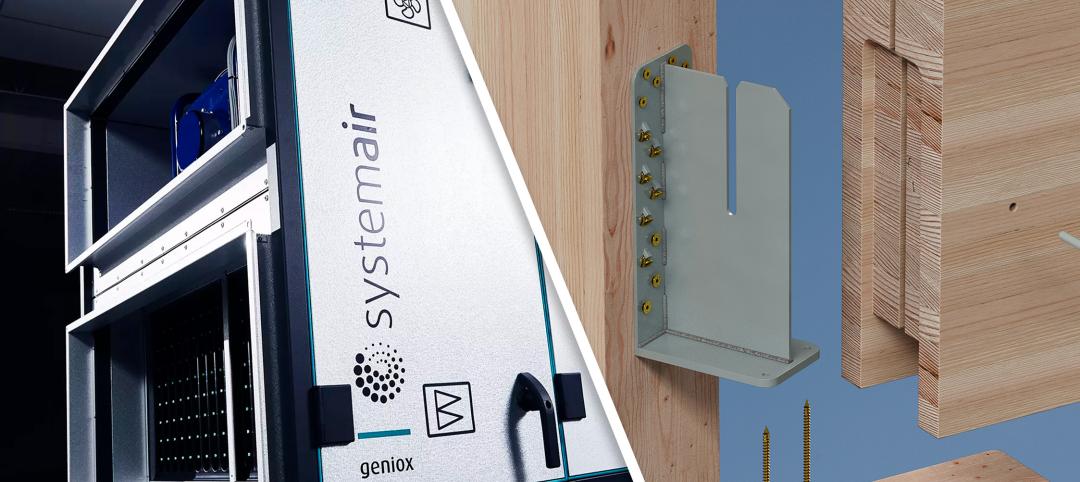

Top building products for October 2023

BD+C Editors break down 15 of the top building products this month, from structural round timber to air handling units.

Building Materials | Oct 19, 2023

New white papers offer best choices in drywall, flooring, and insulation for embodied carbon and health impacts

“Embodied Carbon and Material Health in Insulation” and “Embodied Carbon and Material Health in Gypsum Drywall and Flooring,” by architecture and design firm Perkins&Will in partnership with the Healthy Building Network, advise on how to select the best low-carbon products with the least impact on human health.

Engineers | Oct 12, 2023

Building science: Considering steel sheet piles for semi-permanent or permanent subsurface water control for below-grade building spaces

For projects that do not include moisture-sensitive below-grade spaces, project teams sometimes rely on sheet piles alone for reduction of subsurface water. Experts from Simpson Gumpertz & Heger explore this sheet pile “water management wall” approach.

Building Materials | Oct 2, 2023

Purdue engineers develop intelligent architected materials

Purdue University civil engineers have developed innovative materials that can dissipate energy caused by various physical stresses without sustaining permanent damage.