Engineered as an alternative to traditional building core construction methods, such as cast-in-place concrete, precast concrete, and masonry, this patented, steel-and-concrete hybrid system can simplify and accelerate the construction of reinforced concrete stair and elevator core structures.

The CorTek Core System is supplied by Vulcraft, a fabricator of steel joist and deck components, in collaboration with its parent company, steel producer Nucor.

The newly launched system has been used on five projects to date, including the One Steamboat Place resort in Steamboat Springs, Colo., the Taxi II mixed-use residential building in Denver, and Limelight Lodge in Aspen, Colo.

The system is made up of modular, stackable cores that are factory-built and shipped ready to install. Modular construction minimizes site time and provides easy on-site installation. Stairs are pre-installed at the factory, and the stair rails are shipped inside the cores. This allows for safer, earlier, and more efficient trade access to floors. Workers can begin setting steel right away without having to wait on core curing.

Each CorTek system is custom-built to the requirements of the specific project. The architect and structural engineer are responsible for producing drawings and specifications that define the requirements for the core walls and stairs in the final constructed form. These drawings and specifications are given to the CorTek sub-contractor in order to begin shop drawings.

Once the all-steel cores are delivered on site, the CorTek installation process entails three steps: stack the cores; connect the steel, then continue erecting the structure; and pour concrete inside the core walls as erection continues.

The CorTek system is compatible with steel, concrete, and wood framing, and is structurally equivalent to cast-in-place concrete walls of various thicknesses, according to the makers. The modules go up with floor framing and do not require stripping. The interior surfaces can be left as is or finished with any standard wall

finish, such as paint, drywall, or laminate.

Related Stories

75 Top Building Products | Apr 22, 2024

Enter today! BD+C's 75 Top Building Products for 2024

BD+C editors are now accepting submissions for the annual 75 Top Building Products awards. The winners will be featured in the November/December 2024 issue of Building Design+Construction.

AEC Tech | Feb 20, 2024

AI for construction: What kind of tool can artificial intelligence become for AEC teams?

Avoiding the hype and gathering good data are half the battle toward making artificial intelligence tools useful for performing design, operational, and jobsite tasks.

Sustainability | Nov 1, 2023

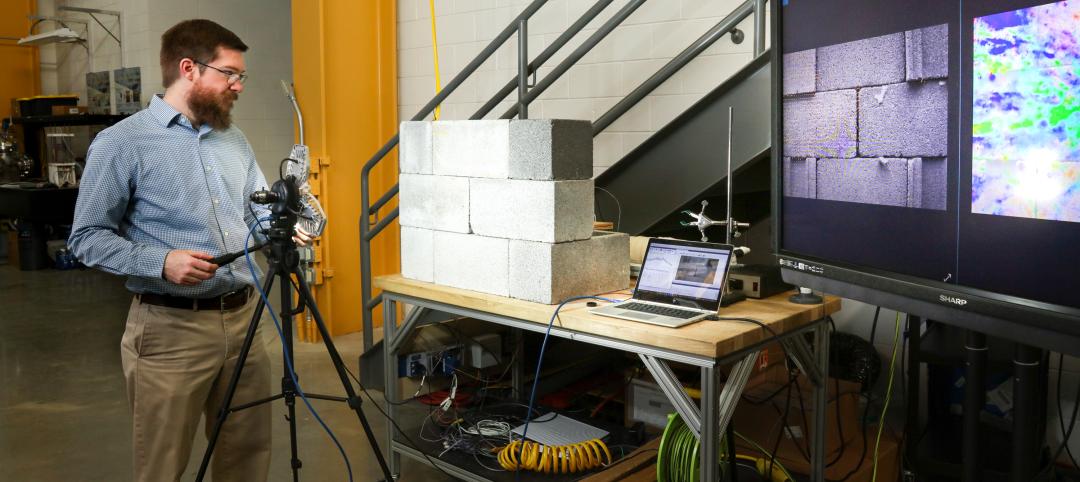

Researchers create building air leakage detection system using a camera in real time

Researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory have developed a system that uses a camera to detect air leakage from buildings in real time.

Resiliency | Aug 7, 2023

Creative ways cities are seeking to beat urban heat gain

As temperatures in many areas hit record highs this summer, cities around the world are turning to creative solutions to cope with the heat. Here are several creative ways cities are seeking to beat urban heat gain.

AEC Innovators | Jun 15, 2023

Rogers-O'Brien Construction pilots wearables to reduce heat-related injuries on jobsites

Rogers-O'Brien Construction (RO) has launched a pilot program utilizing SafeGuard, a safety-as-a-service platform for real-time health and safety risk assessment. Non-invasive wearables connected to SafeGuard continuously monitor personnel to prevent heat exhaustion on jobsites, reducing the risk of related injuries. RO is the first general contractor to pilot this program.

Office Buildings | May 15, 2023

Sixteen-story office tower will use 40% less energy than an average NYC office building

This month marks the completion of a new 16-story office tower that is being promoted as New York City’s most sustainable office structure. That boast is backed by an innovative HVAC system that features geothermal wells, dedicated outdoor air system (DOAS) units, radiant heating and cooling, and a sophisticated control system to ensure that the elements work optimally together.

Design Innovation Report | Apr 27, 2023

BD+C's 2023 Design Innovation Report

Building Design+Construction’s Design Innovation Report presents projects, spaces, and initiatives—and the AEC professionals behind them—that push the boundaries of building design. This year, we feature four novel projects and one building science innovation.

Design Innovation Report | Apr 19, 2023

Reinforced concrete walls and fins stiffen and shade the National Bank of Kuwait skyscraper

When the National Bank of Kuwait first conceived its new headquarters more than a decade ago, it wanted to make a statement about passive design with a soaring tower that could withstand the extreme heat of Kuwait City, the country’s desert capital.

Design Innovation Report | Apr 19, 2023

HDR uses artificial intelligence tools to help design a vital health clinic in India

Architects from HDR worked pro bono with iKure, a technology-centric healthcare provider, to build a healthcare clinic in rural India.

3D Printing | Apr 11, 2023

University of Michigan’s DART Laboratory unveils Shell Wall—a concrete wall that’s lightweight and freeform 3D printed

The University of Michigan’s DART Laboratory has unveiled a new product called Shell Wall—which the organization describes as the first lightweight, freeform 3D printed and structurally reinforced concrete wall. The innovative product leverages DART Laboratory’s research and development on the use of 3D-printing technology to build structures that require less concrete.