Engineered as an alternative to traditional building core construction methods, such as cast-in-place concrete, precast concrete, and masonry, this patented, steel-and-concrete hybrid system can simplify and accelerate the construction of reinforced concrete stair and elevator core structures.

The CorTek Core System is supplied by Vulcraft, a fabricator of steel joist and deck components, in collaboration with its parent company, steel producer Nucor.

The newly launched system has been used on five projects to date, including the One Steamboat Place resort in Steamboat Springs, Colo., the Taxi II mixed-use residential building in Denver, and Limelight Lodge in Aspen, Colo.

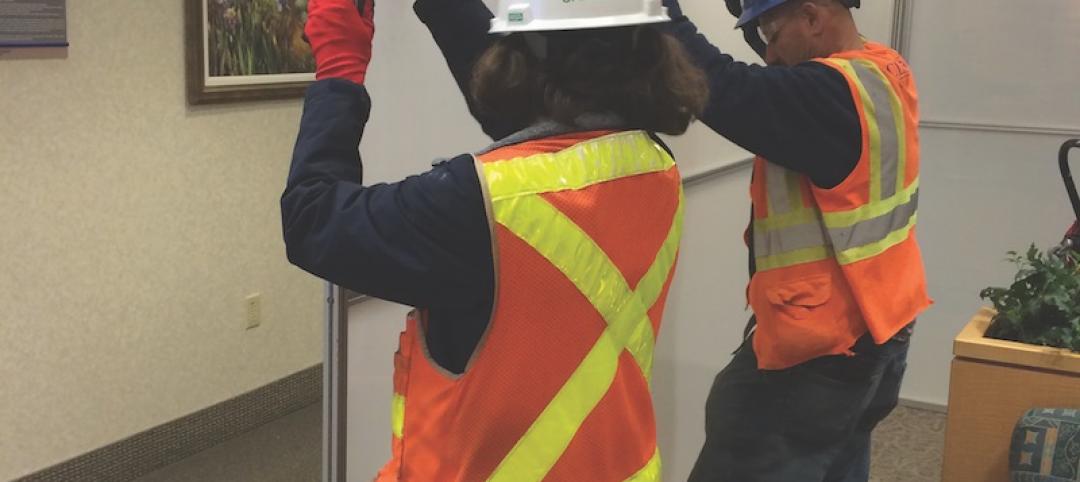

The system is made up of modular, stackable cores that are factory-built and shipped ready to install. Modular construction minimizes site time and provides easy on-site installation. Stairs are pre-installed at the factory, and the stair rails are shipped inside the cores. This allows for safer, earlier, and more efficient trade access to floors. Workers can begin setting steel right away without having to wait on core curing.

Each CorTek system is custom-built to the requirements of the specific project. The architect and structural engineer are responsible for producing drawings and specifications that define the requirements for the core walls and stairs in the final constructed form. These drawings and specifications are given to the CorTek sub-contractor in order to begin shop drawings.

Once the all-steel cores are delivered on site, the CorTek installation process entails three steps: stack the cores; connect the steel, then continue erecting the structure; and pour concrete inside the core walls as erection continues.

The CorTek system is compatible with steel, concrete, and wood framing, and is structurally equivalent to cast-in-place concrete walls of various thicknesses, according to the makers. The modules go up with floor framing and do not require stripping. The interior surfaces can be left as is or finished with any standard wall

finish, such as paint, drywall, or laminate.

Related Stories

Great Solutions | Aug 23, 2016

Visual energy model database demystifies net-zero design

Diamond Schmitt Architects’ ecoMetrics tool allows its designers to quickly analyze solutions based on models from 44 LEED-certified projects.

Great Solutions | Aug 23, 2016

Reusable infection control barriers ease hospital renovation

Clark Construction Group pilots the Edge Guard system on the Fair Oaks (Va.) Hospital reconstruction project.

Great Solutions | Aug 23, 2016

Novel construction approach speeds K-12 school projects

The Folia system uses pre-engineered components to deliver school buildings at 20% less cost.

Great Solutions | Aug 23, 2016

Mobile emergency room arrives just in time for Alabama hospital

The MED-1 Mobile Hospital Unit serves as a lower-cost solution during construction of new ED.

Great Solutions | Aug 23, 2016

Durable coffeemaker brings a bit of comfort to job sites

The CoffeeBoxx is lightweight rust proof, dust proof, water resistant, and ultra durable.

Great Solutions | Aug 23, 2016

Reclaimed wood paneling adds color to retail and hospitality projects

Colorburst panels are available in four stock options—Robin Egg Blue, Viridian Green, Haute Pink, and Cascade White—as well as custom colors.

Great Solutions | Aug 23, 2016

Biophilic pods beat the shade when it comes to outdoor cooling

The Xylem concept by CallisonRTKL regulates outdoor thermal comfort through shading, air movement, water circulation, and a vegetated roof.

Great Solutions | Aug 23, 2016

Mini-grant R&D program pays off in a big way for AE firm

Created through funding from Little’s LaceUp program, the Center for Building Performance has helped the design firm win 14 new jobs since its inception.

Great Solutions | Aug 23, 2016

At Beyer Blinder Belle everyone’s seeing RED

The firm’s R&D initiative inspires its designers to develop ideas that could positively disrupt the practice.

Great Solutions | Aug 23, 2016

Virtual care facility serves remote patients, may reduce readmissions

Mercy’s new high-tech medical center equips its medical professionals to deliver care at the bedside of patients anywhere.