Publix, the largest employee-owned supermarket chain in the U.S., has gotten approval to move forward on a $400 million distribution campus in McLeansville, N.C.

On July 10, a year after Publix announced its plans for the campus, the Water Quality Committee of the North Carolina Environmental Management Commission approved the request to commence construction of the distribution facility, which would be Publix’s 10th.

That campus will include a 1.1-million-sf refrigerated warehouse, a 120,000-sf food manufacturing facility, and a 1.3-million-sf dry warehouse. It is expected to generate 1,000 new jobs after it’s completed in late 2021 or early 2022.

Publix has selected LEO A DALY and its subsidiary engineering firm Lockwood, Andrews & Newman to design the refrigerated/frozen food part of the campus, which would be the retailer’s northern-most distribution point. (Currently, 38 of Publix’s 1,200-pus supermarkets are located in North Carolina.) LEO A DALY and LAN will provide architecture and engineering services, including fire-protection, refrigeration engineering, and sustainability consulting.

The GC on this project was not disclosed at presstime.

This project is design-bid-build. “The market sector is moving toward a design-build delivery method, but in this case, Publix will benefit from the design-led approach, with all disciplines in-house,” Mike Schmidt, AIA, NCARB, market-sector leader for food, distribution, and manufacturing in LEO A DALY’s West Palm Beach, Fla., design studio, tells BD+C. “Design-bid-build allows us to work directly with the client to understand its unique needs and deliver a more customized solution. We’re focused on innovative space planning, improvement the employee experience, and creating more efficient building systems.”

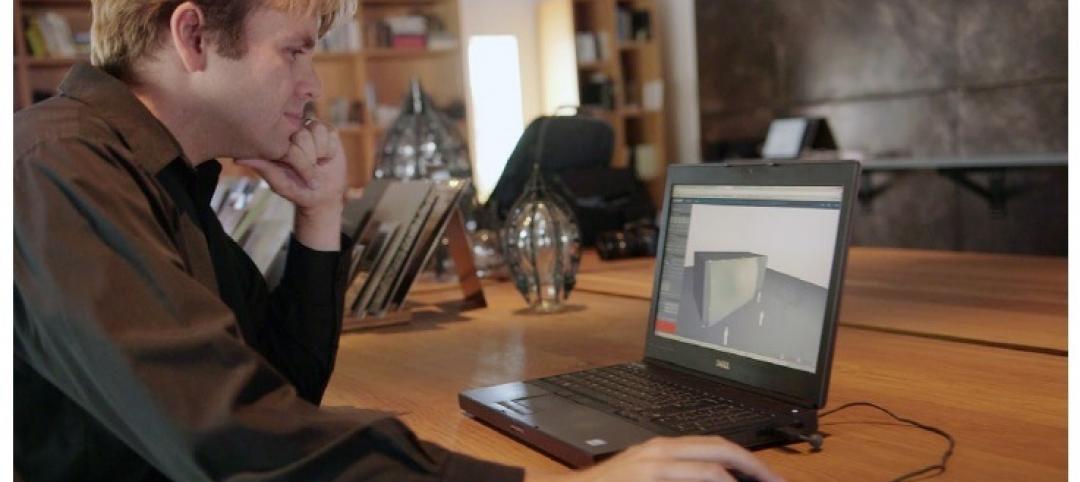

The North Carolina warehouse will be comparable to Publix’s DC in Orlando, Fla., which LEO A DALY designed. The design team intends to use BIM to track costs through the design process, and VR to plan spaces, get faster client feedback, and reduce waste.

Related Stories

| Apr 9, 2014

Steel decks: 11 tips for their proper use | BD+C

Building Teams have been using steel decks with proven success for 75 years. Building Design+Construction consulted with technical experts from the Steel Deck Institute and the deck manufacturing industry for their advice on how best to use steel decking.

| Apr 2, 2014

8 tips for avoiding thermal bridges in window applications

Aligning thermal breaks and applying air barriers are among the top design and installation tricks recommended by building enclosure experts.

| Mar 26, 2014

Callison launches sustainable design tool with 84 proven strategies

Hybrid ventilation, nighttime cooling, and fuel cell technology are among the dozens of sustainable design techniques profiled by Callison on its new website, Matrix.Callison.com.

| Mar 20, 2014

Common EIFS failures, and how to prevent them

Poor workmanship, impact damage, building movement, and incompatible or unsound substrate are among the major culprits of EIFS problems.

| Mar 20, 2014

Fluor defines the future 7D deliverable without losing sight of real results today

A fascinating client story by Fluor SVP Robert Prieto reminds us that sometimes it’s the simplest details that can bring about real results today—and we shouldn’t overlook them, even as we push to change the future state of project facilitation.

| Mar 19, 2014

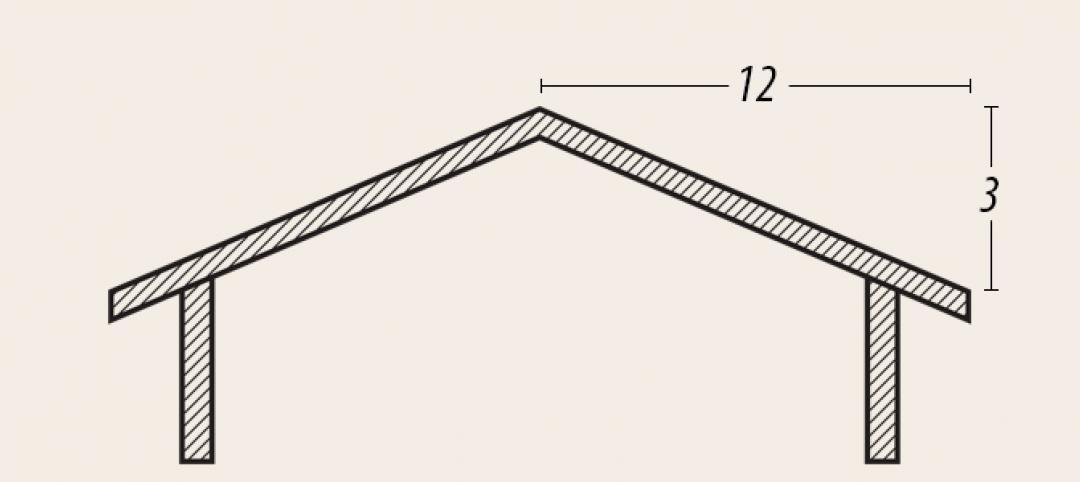

Frames: the biggest value engineering tip

In every aspect of a metal building, you can tweak the cost by adjusting the finish, panel thickness, and panel profile. These changes might make a few percentage points difference in the cost. Change the framing and you have the opportunity to affect 10-20 percent savings to the metal building portion of the project.

| Mar 12, 2014

14 new ideas for doors and door hardware

From a high-tech classroom lockdown system to an impact-resistant wide-stile door line, BD+C editors present a collection of door and door hardware innovations.

Sponsored | | Mar 10, 2014

A high-performance barn

Bastoni Vineyards replaces a wooden barn with an efficient metal building used for maintenance, storage, and hosting events.

| Jan 28, 2014

16 awe-inspiring interior designs from around the world [slideshow]

The International Interior Design Association released the winners of its 4th Annual Global Excellence Awards. Here's a recap of the winning projects.

| Jan 13, 2014

Custom exterior fabricator A. Zahner unveils free façade design software for architects

The web-based tool uses the company's factory floor like "a massive rapid prototype machine,” allowing designers to manipulate designs on the fly based on cost and other factors, according to CEO/President Bill Zahner.