Over the years, Pepper Construction, like most general contractors, has hit its share of underground utilities installed beneath jobsites. “That’s not a phone call the CEO of our company wants to get,” says Mike Alder, Virtual Construction Manager at Pepper’s office in Indianapolis.

These breaches have occurred despite standards and protocols that have been in place for decades to identify and avoid underground pipes, wiring, and cables. Pepper typically hires a public or private locating company—depending on who owns the land—that relies on a combination of schematics on record, what’s visible above ground, and what’s underground that can be tracked by certain equipment. Sometimes, excavation is required.

But a few years ago, Pepper started asking itself whether there was a better way to locate and avoid hitting utilities. This is particularly important for hospital projects, says Alder, “where you don’t want to disrupt service and what might be on the other side of that service.”

In conversations with its field crews and subs, Pepper heard over and over again that the lack of communication and subpar information were the culprits behind these collisions. “We walked out of those meetings with the notion that everyone had a victim mentality,” says Alder.

At one of those meetings, Pepper’s safety director, Dave Murphy, made what Alder recalls as an “obvious but profound” observation that “we hit underground utilities because we can’t see them.” Soon after, in 2017, Murphy and Alder started working together to create underground 3D models. “Civil drawings just weren’t enough anymore,” says Alder.

Their first step was to gather site drawings, and then overlay them with the new utilities and building that were being installed. Using those images as guides, Pepper then went to the site with a Vac truck, which Alder describes as a giant dirt vacuum, to further locate the buried utilities and to mark them by putting six-inch pipes into the ground.

Pepper had been doing all of this before. But now, it was also surveying the site, and bringing those survey points into modeling software. Alder says his company also creates 3D models for the project’s new utilities. “The benefit of this is that we were finding places where there were clashes between the old and new utilities.”

Pepper shares this information with its field crews, giving them better reconnaissance.

Crew members look at models showing where underground utlities are located on jobsites. Image: Pepper Construction.

Crew members look at models showing where underground utlities are located on jobsites. Image: Pepper Construction.

The firm has done underground 3D models for more than a dozen projects, and over time has made some tweaks to its process. For one thing, it’s been trying to get Civil Engineers on projects more involved upfront in the drawings and surveying during the design phase.

Pepper also flies drones over its jobsites to capture imagery that can be used to create 2D maps of the site, which Alder says gives the underground 3D models more perspective.

The modeling of underground utilities is now standard operating procedure for Pepper’s Indiana office. (Alder couldn’t say whether the firm’s other offices were following suit.). “If we had waited for the process to be perfect, we probably wouldn’t have rolled this out yet.”

Pepper is looking attempting to leveraging technology to create better models faster, and to produce a more dynamic deliverable, which will mean getting crews in the field more involved in up-to-the-minute the data collection.

“It’s important to realize that this has been a big endeavor for us,” says Alder. “It’s like flipping the industry on its head.” He notes, though, that the biggest obstacle to more widespread underground 3D modeling continues to be the cost it adds to the project, and the potential for adding more time, too, if it’s not scheduled properly.

Related Stories

AEC Tech | Oct 6, 2017

How professional bias can sabotage industry transformation

Professional bias can take the form of change-resistant thinking that can keep transformational or innovative ambitions at bay. Tech consultant Nate Miller presents three kinds of bias that often emerge when a professional is confronted with new technology.

AEC Tech | Aug 25, 2017

Software cornucopia: Jacksonville Jaguars’ new practice facility showcases the power of computational design

The project team employed Revit, Rhino, Grasshopper, Kangaroo, and a host of other software applications to design and build this uber-complex sports and entertainment facility.

AEC Tech | Aug 24, 2017

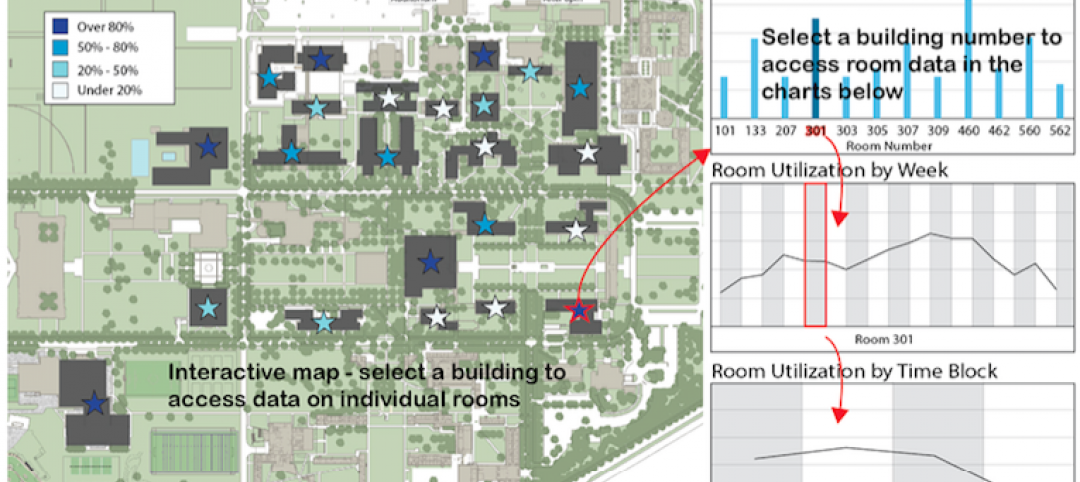

Big Data helps space optimization, but barriers remain

Space optimization is a big issue on many university campuses, as schools face increasing financial constraints, writes Hanbury’s Jimmy Stevens.

Lighting | Aug 2, 2017

Dynamic white lighting mimics daylighting

By varying an LED luminaire’s color temperature, it is possible to mimic daylighting, to some extent, and the natural circadian rhythms that accompany it, writes DLR Group’s Sean Avery.

Office Buildings | Jul 20, 2017

SGA uses virtual design and construction technology to redevelop N.Y. building into modern offices

287 Park Avenue South is a nine-story Classical Revival building previously known as the United Charities Building.

Accelerate Live! | Jul 6, 2017

Watch all 20 Accelerate Live! talks on demand

BD+C’s inaugural AEC innovation conference, Accelerate Live! (May 11, Chicago), featured talks on machine learning, AI, gaming in construction, maker culture, and health-generating buildings.

| Jun 13, 2017

Accelerate Live! talk: Is the road to the future the path of least resistance? Sasha Reed, Bluebeam (sponsored)

Bluebeam’s Sasha Reed discusses why AEC leaders should give their teams permission to responsibly break things and create ecosystems of people, process, and technology.

| Jun 13, 2017

Accelerate Live! talk: 3D laser scanning for the project lifecycle, FARO Technologies (sponsored)

Brent Slawnikowski of FARO Technologies and Jennifer Suerth of Pepper Construction discuss how implementation of laser scanning has helped Pepper become more successful in the completion of their projects.

| Jun 13, 2017

Accelerate Live! talk: Incubating innovation through R&D and product development, Jonatan Schumacher, Thornton Tomasetti

Thornton Tomasetti’s Jonatan Schumacher presents the firm’s business model for developing, incubating, and delivering cutting-edge tools and solutions for the firm, and the greater AEC market.

| Jun 13, 2017

Accelerate Live! talk: The future of computational design, Ben Juckes, Yazdani Studio of CannonDesign

Yazdani’s Ben Juckes discusses the firm’s tech-centric culture, where scripting has become an every-project occurrence and each designer regularly works with computational tools as part of their basic toolset.