Freres Lumber of Lyons, Ore., announced the development of a new-to-market innovative wood product, Mass Plywood Panel (MPP). The veneer-based engineered wood product currently is being tested and refined through a partnership with Oregon State University (OSU). Patents are pending.

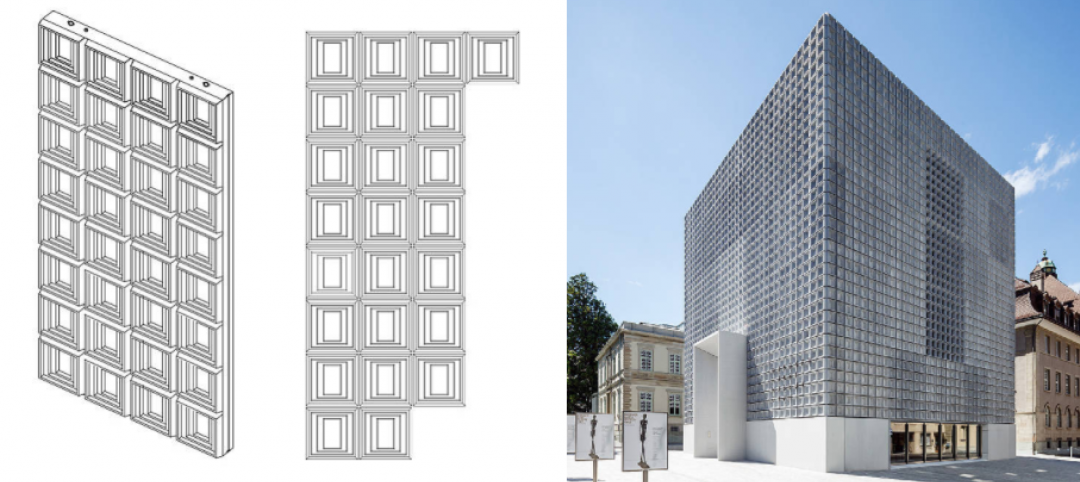

MPP is a massive, large-scale plywood panel with maximum finished panel dimensions up to 12 feet wide by 48 feet long and up to 24 inches thick. The panels may be customized to fit specific projects; constructed in one-inch thick increments that provide superior strength and performance.

MPP is an alternative to cross laminated timber (CLT), a recent engineered lumber panel that allows wood products to be used for multi-story buildings, while also increasing the speed of construction. While both are new wood product innovations, the MPP uses engineered veneer and custom plywood layups as a base material rather than lumber.

“We believe veneer is the most appropriate raw material for Mass Timber Panels in the Pacific Northwest. Our veneer plants can efficiently and responsibly use second and third growth timber with a minimum of a 5-inch block diameter to produce engineered panels. Natural defects within the log are engineered out of the raw material prior to constructing the mass panel by virtue of the traditional plywood laminating process. The compounded veneer layers, and the ability to engineer each individual layer means that we can customize the panels to specific engineering needs.

Studies conducted at Oregon State University show that by using veneer as a raw material for a Mass Timber Panel, we can potentially achieve the same structural attributes of a CLT panel with 20 to 30 percent less wood,” says Tyler Freres, Vice President of Sales for Freres Lumber Co., Inc.

The company cites several advantages of the MPP product, including the opportunity for these large format panels to be manufactured at the production facility to include window, door and all other required cut-outs, which will minimize waste and labor on the job site. The relative lightness of the panels can also help transportation costs and logistics when constructing buildings on the job site. That, plus the aesthetic appeal of wood makes MPP a competitive new option.

The development of this product was made possible through a partnership with researchers at Oregon State University College of Forestry and the new Center for Advanced Wood Products established to help drive new and innovative uses of wood in buildings. “The Center and OSU faculty provided affordable product testing, panel engineering expertise, and a clear avenue for future product development with potential clients. They will continue to be an important partner as we bring the product from concept to a marketable reality,” says Freres.

Resin supplier, Hexion, has not only provided expertise, but also provided the cold-press resin used for all preliminary panel testing. “They have been instrumental with the product development,” says Freres.

Freres says, “This product has the ability to dramatically change the West Coast veneer and panel products industry to produce high-quality, structurally superior homes and buildings at much more affordable prices. It can potentially alleviate current building constraints of labor and land availability by allowing contractors to build quicker and taller with fewer workers.”

Related Stories

| Aug 11, 2010

Draft NIST report on Cowboys practice facility collapse released for public comment

A fabric-covered, steel frame practice facility owned by the National Football League’s Dallas Cowboys collapsed under wind loads significantly less than those required under applicable design standards, according to a report released today for public comment by the Commerce Department's National Institute of Standards and Technology (NIST).

| Aug 11, 2010

Concrete Solutions

About five or six years ago, officials at the University of California at Berkeley came to the conclusion that they needed to build a proper home for the university's collection of 900,000 rare Chinese, Japanese, and Korean books and materials. East Asian studies is an important curriculum at Berkeley, with more than 70 scholars teaching some 200 courses devoted to the topic, and Berkeley's pro...

| Aug 11, 2010

Piano's 'Flying Carpet'

Italian architect Renzo Piano refers to his $294 million, 264,000-sf Modern Wing of the Art Institute of Chicago as a “temple of light.” That's all well and good, but how did Piano and the engineers from London-based Arup create an almost entirely naturally lit interior while still protecting the priceless works of art in the Institute's third-floor galleries from dangerous ultravio...

| Aug 11, 2010

Great Solutions: Green Building

27. Next-Generation Green Roofs Sprout up in New York New York is not particularly known for its green roofs, but two recent projects may put the Big Apple on the map. In spring 2010, the Lincoln Center for the Performing Arts will debut one of the nation's first fully walkable green roofs. Located across from the Juilliard School in Lincoln Center's North Plaza, Illumination Lawn will consist ...

| Aug 11, 2010

Nurturing the Community

The best seat in the house at the new Seahawks Stadium in Seattle isn't on the 50-yard line. It's in the southeast corner, at the very top of the upper bowl. "From there you have a corner-to-corner view of the field and an inspiring grasp of the surrounding city," says Kelly Kerns, project leader with architect/engineer Ellerbe Becket, Kansas City, Mo.

| Aug 11, 2010

Thrown For a Loop in China

While the Bird's Nest and Water Cube captured all the TV coverage during the Beijing Olympics in August, the Rem Koolhaas-designed CCTV Headquarters in Beijing—known as the “Drunken Towers” or “Big Shorts,” for its unusual shape—is certain to steal the show when it opens next year.

| Aug 11, 2010

World's tallest all-wood residential structure opens in London

At nine stories, the Stadthaus apartment complex in East London is the world’s tallest residential structure constructed entirely in timber and one of the tallest all-wood buildings on the planet. The tower’s structural system consists of cross-laminated timber (CLT) panels pieced together to form load-bearing walls and floors. Even the elevator and stair shafts are constructed of prefabricated CLT.

Concrete | Aug 11, 2010

8 Innovations That Will Rock Your Next Concrete Project

If you think you've seen it all when it comes to concrete construction, then you haven't sat down with Blaine Brownell. The architect-turned-blogger-turned-author has become the industry's foremost expert in everything that is unconventional and provocative in the building products field. For the past eight years, this LEED Accredited Professional, BD+C “40 Under 40” winner, and vis...

| Aug 11, 2010

Great Solutions: Products

14. Mod Pod A Nod to Flex Biz Designed by the British firm Tate + Hindle, the OfficePOD is a flexible office space that can be installed, well, just about anywhere, indoors or out. The self-contained modular units measure about seven feet square and are designed to serve as dedicated space for employees who work from home or other remote locations.