For years, the steel joist industry standard has been that loads either need to be applied at panel points, or a member brace (strut) must be added in the field. In response to inquiries from structural engineers and other members of the Building Team, the Steel Joist Institute recently issued a new rule for loads not exceeding 100 pounds within any given panel.

The full text of the SJI rule reads as follows: “For nominal concentrated loads between panel points, which have been accounted for in the specified uniform design loads, a strut to transfer the load to a panel point on the opposite chord shall not be required, provided the sum of the concentrated loads within a chord panel does not exceed 100 pounds and the attachments are concentric to the chord.”

Bruce Brothersen, engineering manager for Vulcraft-Utah, Brigham, Utah, says, “The rule is an attempt to better define what is acceptable and put some quantitative numbers to it.”

Tim Holtermann, corporate engineering manager for Canam Steel in Washington, Mo., says that even with the new rule, manufacturers remain concerned that “people may be hanging things in excess of 100 pounds away from panel points and not field-adding struts, as they’re required to do.”

Holtermann says one option for structural engineers is to ask the manufacturer to provide a specially designed joist that can take point loads over 100 pounds without the added members. “It’s not uncommon to have a design requirement for, say, 250 pounds or 400 pounds,” he says. “We can readily do that as long as the magnitude of the loads and this design requirement are specified on the contract drawings.”

DON’T WAIT FOR THE FINAL PUNCH LIST

Often the problem with the joist loads isn’t discovered until the project is completed and the final walkthrough is taking place, says Joe Pote, director of research and development for New Millennium Building Systems, Hope, Ark.

“The inspector notices ductwork or sprinkler lines or mechanicals hanging from the joists between panel points that aren’t called out on the contract drawings,” says Pote. “Then he comes back to us and asks if it’s okay.” Many times the loads are small (20-50 pounds), so additional reinforcement isn’t necessary. “But we never had a good rule that stated the maximum load,” he says. “I think it helps clear up some of the discrepancy between SJI requirements and actual field practice.”

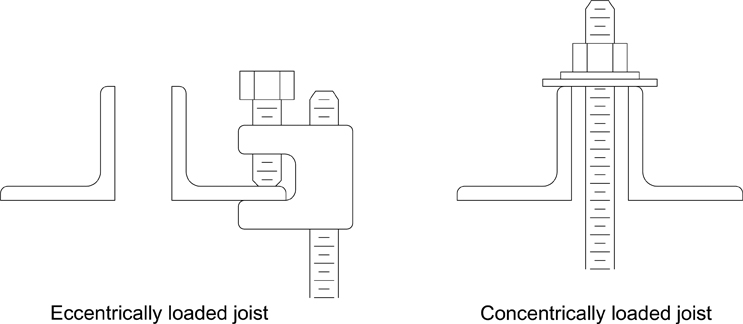

The manner in which the loads are hung is a key element of the 100-pound rule, says Holtermann. “The rule presumes that the load will be placed concentrically,” he says.

As SJI managing director Ken Charles notes, some trade installers make the mistake of attaching beam clamps to only one bottom chord angle of the joist instead of both. On top of that, he says, “the load isn’t placed concentrically even to that one chord angle, so you’re inducing some torsion and bending of the horizontal leg of the angle.”

His advice: “By far the better way to do it is to make sure the attachment is always concentric and always attached to both chord angles.” (See diagram.)

Steel Joist Do’s and Don’ts

- Recognize how and when to specify total uniform load or factored load and/or net uplift load, and when loads need to be broken out by load category and combinations.

- Know the limits of a concentrated load applied between panel points before an additional web is needed on the joist. The Steel Joist Institute’s new “100-pound rule” clarifies these limits.

- Install bridging early and follow the proper procedures to avoid safety problems, such as a partial building collapse.

- Designate a field representative to inspect the joists during construction and ensure that components are being installed correctly.Ideally, a representative of the team should walk the job site before completion and look for situations where loads aren’t handled correctly.

“A lot of times there’s a disconnect between the design intent and the construction site personnel,” says Charles. “Some sites have representatives in the field to do inspections, but often that’s not the case. Those are the projects that are most likely to have problems down the road when the final punch list is done.”

GET YOUR SPECS STRAIGHT

Joists are designed to handle different types of loads, such as dead load, live load, and wind, snow, and seismic loads. A given joist might experience more than one type of load, so the joist manufacturer needs to know which loads apply and properly combine them according to parameters set by the International Building Code. Most jurisdictions use the 2006 version of the IBC or the 2009 version, which is similar with regard to steel joists.

Brothersen notes that the building code loading combinations are based on the probability of which loads will act simultaneously. “For instance, the probability of a seismic event occurring when the maximum snow load is on the joist is relatively small, so the building code reduces the loads in those cases,” he says. “This is more realistic and doesn’t require manufacturers to design for the maximum load in every category at the same time.”

Pote says manufacturers prefer, when it’s feasible, that loads be provided to them as either a total uniform load or a factored load. In other words, if all components of the joist can be designed for a single downward-acting load case and a single upward-acting load case, the easiest thing for engineers to do is provide the total uniform load and/or net uplift load (dead load minus wind load).

“It’s just easier to communicate,” says Charles. “However, if we have to consider multiple load combinations, we need the breakdown—dead load, live load, snow load, and so forth.”

Holtermann adds that if the structure might be affected by downward-acting winds, the total uniform load should assume the worst-case scenario.

DON’T FORGET THE BRIDGING

Once the joists arrive on site, it’s important that bridging be installed early and correctly, says Brothersen. “If the joists are put up but the bridging isn’t installed, it can become a safety issue.” For example, lack of bridging can result in a partial building collapse when the crew begins stacking bundles of deck material on the joists.

Charles agrees. “The best-laid plans of the engineer and manufacturer can go out the window when the product arrives at the job site and the erector doesn’t follow proper safety regulations and the manufacturer’s advice.” BD+C

--

Editor’s note: To order SJI’s “43rd Edition Catalog of Standard Specifications and Load and Weight Tables for Steel Joists and Joist Girders,” go to: http://steeljoist.org/free-download-form.

Related Stories

| Aug 11, 2010

Colonnade fixes setback problem in Brooklyn condo project

The New York firm Scarano Architects was brought in by the developers of Olive Park condominiums in the Williamsburg section of Brooklyn to bring the facility up to code after frame out was completed. The architects designed colonnades along the building's perimeter to create the 15-foot setback required by the New York City Planning Commission.

| Aug 11, 2010

Wisconsin becomes the first state to require BIM on public projects

As of July 1, the Wisconsin Division of State Facilities will require all state projects with a total budget of $5 million or more and all new construction with a budget of $2.5 million or more to have their designs begin with a Building Information Model. The new guidelines and standards require A/E services in a design-bid-build project delivery format to use BIM and 3D software from initial ...

| Aug 11, 2010

Opening night close for Kent State performing arts center

The curtain opens on the Tuscarawas Performing Arts Center at Kent State University in early 2010, giving the New Philadelphia, Ohio, school a 1,100-seat multipurpose theater. The team of Legat & Kingscott of Columbus, Ohio, and Schorr Architects of Dublin, Ohio, designed the 50,000-sf facility with a curving metal and glass façade to create a sense of movement and activity.

| Aug 11, 2010

Residence hall designed specifically for freshman

Hardin Construction Company's Austin, Texas, office is serving as GC for the $50 million freshman housing complex at the University of Houston. Designed by HADP Architecture, Austin, the seven-story, 300,000-sf facility will be located on the university's central campus and have 1,172 beds, residential advisor offices, a social lounge, a computer lab, multipurpose rooms, a fitness center, and a...

| Aug 11, 2010

News Briefs: GBCI begins testing for new LEED professional credentials... Architects rank durability over 'green' in product attributes... ABI falls slightly in April, but shows market improvement

News Briefs: GBCI begins testing for new LEED professional credentials... Architects rank durability over 'green' in product attributes... ABI falls slightly in April, but shows market improvement

| Aug 11, 2010

Luxury Hotel required faceted design

Goettsch Partners, Chicago, designed a new five-star, 214-room hotel for the King Abdullah Financial District (KAFD) in Riyadh, Saudi Arabia. The design-build project, with Saudi Oger Ltd. as contractor and Rayadah Investment Co. as developer, has a three-story podium supporting a 17-story glass tower with a nine-story opening that allows light to penetrate the mass of the building.

| Aug 11, 2010

Three Schools checking into L.A.'s Ambassador Hotel site

Pasadena-based Gonzalez Goodale Architects is designing three new schools for Los Angeles Unified School District's Central Wilshire District. The $400 million campus, located on the site of the former Ambassador Hotel, will house a K-5 elementary school, a middle school, a high school, a shared recreation facility (including soccer field, 25-meter swimming pool, two gymnasiums), and a new publ...

| Aug 11, 2010

New Jersey's high-tech landscaping facility

Designed to enhance the use of science and technology in Bergen County Special Services' landscaping programs, the new single-story facility at the technical school's Paramus campus will have 7,950 sf of classroom space, a 1,000-sf greenhouse (able to replicate different environments, such as rainforest, desert, forest, and tundra), and 5,000 sf of outside landscaping and gardening space.