When it comes to building architecture in space, researchers, scientists, and architects have been offering up possible solutions for years. Concrete made from soil, ice shelters, and those grown from fungus have all been offered up as possible building materials. But a new possible building method may just use the most unique component of them all: urine.

Norwegian, Spanish, Italian, and Dutch scientists, together with the Advanced Concepts Team (ACT) of the European Space Agency (ESA), have conducted experiments using urea from urine as a superplasticizer for lunar geopolymer mixtures that can then be used to 3D print structures. The scientists presented their findings in the Journal of Cleaner Production.

In their paper titled "Utilization of urea as an accessible superplasticizer on the moon for lunar geopolymer mixters," the scientists say urea can break hydrogen bonds and therefore reduces the viscosities of many aqueous mixtures. And since urea is the second most abundant component of urine (water being the first), it would be readily available, even in a location as barren and distant as the moon.

See Also: Designing for the final frontier: Space architecture

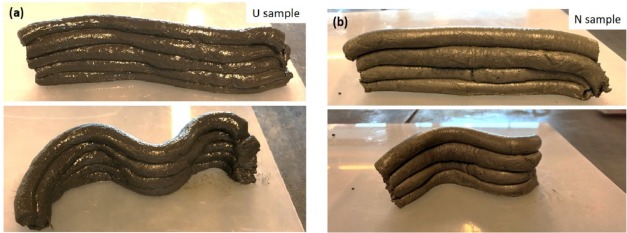

"Addition of urea has been compared with polycarboxylate and naphthalene based superplasticizers, and with a control mixture without superplasticizer. When curing the sample containing urea at 80 °C, the initial setting time became longer. The samples containing urea or naphthalene-based superplasticizers could bear heavy weights shortly after mixing, while keeping an almost stable shape. Samples without superplasticizer or containing the polycarboxylate-based admixture were too stiff for mold-shaped formation after casting. Samples containing urea and naphthalene-based admixtures could be used to build up a structure without any noticeable deformation," according to the paper.

Additionally, the samples with urea also had higher compressive strength than the other two specimens containing superplasticizers, "and it continued to rise even after 8 freeze-thaw cycles."

The scientists conclude the paper by explaining further studies are needed to assess how the lunar regolith geopolymers will behave under the severe lunar conditions, which include a vacuum that can cause the volatile components to evaporate and large temperature fluctuations that can cause the structure to crack.

But if all goes according to plan, Moon Base Number 1 may have a more literal meaning than anyone ever anticipated.

Related Stories

Multifamily Housing | Sep 15, 2022

Toronto’s B-Line Condominiums completed using prefabricated panels

B-Line Condos, Toronto, completed using Sto Panel Technology.

Mass Timber | Aug 30, 2022

Mass timber construction in 2022: From fringe to mainstream

Two Timberlab executives discuss the market for mass timber construction and their company's marketing and manufacturing strategies. Sam Dicke, Business Development Manager, and Erica Spiritos, Director of Preconstruction, Timberlab, speak with BD+C's John Caulfield.

Sponsored | BD+C University Course | Aug 24, 2022

Solutions for cladding performance and supply issues

This course covers design considerations and cladding assembly choices for creating high-performance building envelopes — a crucial element in healthy, energy-efficient buildings.

Sponsored | | Aug 4, 2022

Brighter vistas: Next-gen tools drive sustainability toward net zero line

New technologies, innovations, and tools are opening doors for building teams interested in better and more socially responsible design.

Building Materials | Aug 3, 2022

Shawmut CEO Les Hiscoe on coping with a shaky supply chain in construction

BD+C's John Caulfield interviews Les Hiscoe, CEO of Shawmut Design and Construction, about how his firm keeps projects on schedule and budget in the face of shortages, delays, and price volatility.

Building Materials | Jul 20, 2022

LP Building Solutions celebrates 50th anniversary at NYSE ceremony

LP Building Solutions celebrates 50th anniversary at NYSE ceremony.

Building Materials | Jun 20, 2022

Early-stage procurement: The next evolution of the construction supply chain

Austin Commercial’s Jason Earnhardt explains why supply chain issues for the construction industry are not going to go away and how developers and owners can get ahead of project roadblocks.

Sponsored | BD+C University Course | May 10, 2022

Design guide for parapets: Safety, continuity, and the building code

This course covers design considerations for parapets. The modern parapet must provide fire protection, serve as a fall-protective guard, transition and protect the roof/facade interface, conceal rooftop equipment, and contribute to the aesthetic character of the building.

Sponsored | BD+C University Course | May 10, 2022

Designing smarter places of learning

This course explains the how structural steel building systems are suited to construction of education facilities.

Sponsored | BD+C University Course | May 5, 2022

Designing with architectural insulated metal wall panels

Insulated metal wall panels (IMPs) offer a sleek, modern, and lightweight envelope system that is highly customizable. This continuing education course explores the characteristics of insulated metal wall panels, including how they can offer a six-in-one design solution. Discussions also include design options, installation processes, code compliance, sustainability, and available warranties.