When it comes to building architecture in space, researchers, scientists, and architects have been offering up possible solutions for years. Concrete made from soil, ice shelters, and those grown from fungus have all been offered up as possible building materials. But a new possible building method may just use the most unique component of them all: urine.

Norwegian, Spanish, Italian, and Dutch scientists, together with the Advanced Concepts Team (ACT) of the European Space Agency (ESA), have conducted experiments using urea from urine as a superplasticizer for lunar geopolymer mixtures that can then be used to 3D print structures. The scientists presented their findings in the Journal of Cleaner Production.

In their paper titled "Utilization of urea as an accessible superplasticizer on the moon for lunar geopolymer mixters," the scientists say urea can break hydrogen bonds and therefore reduces the viscosities of many aqueous mixtures. And since urea is the second most abundant component of urine (water being the first), it would be readily available, even in a location as barren and distant as the moon.

See Also: Designing for the final frontier: Space architecture

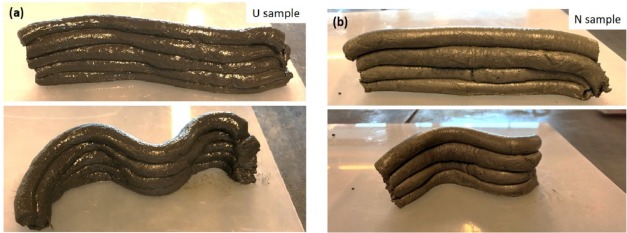

"Addition of urea has been compared with polycarboxylate and naphthalene based superplasticizers, and with a control mixture without superplasticizer. When curing the sample containing urea at 80 °C, the initial setting time became longer. The samples containing urea or naphthalene-based superplasticizers could bear heavy weights shortly after mixing, while keeping an almost stable shape. Samples without superplasticizer or containing the polycarboxylate-based admixture were too stiff for mold-shaped formation after casting. Samples containing urea and naphthalene-based admixtures could be used to build up a structure without any noticeable deformation," according to the paper.

Additionally, the samples with urea also had higher compressive strength than the other two specimens containing superplasticizers, "and it continued to rise even after 8 freeze-thaw cycles."

The scientists conclude the paper by explaining further studies are needed to assess how the lunar regolith geopolymers will behave under the severe lunar conditions, which include a vacuum that can cause the volatile components to evaporate and large temperature fluctuations that can cause the structure to crack.

But if all goes according to plan, Moon Base Number 1 may have a more literal meaning than anyone ever anticipated.

Related Stories

| Nov 2, 2010

11 Tips for Breathing New Life into Old Office Spaces

A slowdown in new construction has firms focusing on office reconstruction and interior renovations. Three experts from Hixson Architecture Engineering Interiors offer 11 tips for office renovation success. Tip #1: Check the landscaping.

| Nov 2, 2010

Cypress Siding Helps Nature Center Look its Part

The Trinity River Audubon Center, which sits within a 6,000-acre forest just outside Dallas, utilizes sustainable materials that help the $12.5 million nature center fit its wooded setting and put it on a path to earning LEED Gold.

| Nov 2, 2010

A Look Back at the Navy’s First LEED Gold

Building Design+Construction takes a retrospective tour of a pace-setting LEED project.

| Nov 2, 2010

Wind Power, Windy City-style

Building-integrated wind turbines lend a futuristic look to a parking structure in Chicago’s trendy River North neighborhood. Only time will tell how much power the wind devices will generate.

| Oct 13, 2010

Prefab Trailblazer

The $137 million, 12-story, 500,000-sf Miami Valley Hospital cardiac center, Dayton, Ohio, is the first major hospital project in the U.S. to have made extensive use of prefabricated components in its design and construction.

| Oct 13, 2010

Biloxi’s convention center bigger, better after Katrina

The Mississippi Coast Coliseum and Convention Center in Biloxi is once again open for business following a renovation and expansion necessitated by Hurricane Katrina.

| Oct 13, 2010

Tower commemorates Lewis & Clark’s historic expedition

The $4.8 million Lewis and Clark Confluence Tower in Hartford, Ill., commemorates explorers Meriwether Lewis and William Clark at the point where their trek to the Pacific Ocean began—the confluence of the Mississippi and Missouri Rivers.

| Oct 13, 2010

Community center under way in NYC seeks LEED Platinum

A curving, 550-foot-long glass arcade dubbed the “Wall of Light” is the standout architectural and sustainable feature of the Battery Park City Community Center, a 60,000-sf complex located in a two-tower residential Lower Manhattan complex. Hanrahan Meyers Architects designed the glass arcade to act as a passive energy system, bringing natural light into all interior spaces.

| Oct 13, 2010

Community college plans new campus building

Construction is moving along on Hudson County Community College’s North Hudson Campus Center in Union City, N.J. The seven-story, 92,000-sf building will be the first higher education facility in the city.

| Oct 12, 2010

Holton Career and Resource Center, Durham, N.C.

27th Annual Reconstruction Awards—Special Recognition. Early in the current decade, violence within the community of Northeast Central Durham, N.C., escalated to the point where school safety officers at Holton Junior High School feared for their own safety. The school eventually closed and the property sat vacant for five years.