Take a sheet of copy paper and grip it flat in your hands. Next, gently push down evenly on both sides to form a smooth curve. Now, twist your left thumb up and your right thumb down. Ta-da! You have created a double-curved surface.

What seems easy to do with paper is not easy to do with glass, especially if you want to integrate photovoltaics into the assembly.

That was the problem that a team from Adrian Smith + Gordon Gill Architecture faced in designing the main exhibition hall for Expo 2017 in Astana, the capital of Kazakhstan. Nursultan Nazerbayev, the country’s president (since 1990), wanted a monumental glass sphere at the center of the 430-acre exhibit grounds to symbolize to the world that his country, while rich in oil (30 billion bbl in reserves) and uranium (it’s the world’s top producer), was leading the way to a post-carbon future. The sphere would live on as a science and technology museum, a reminder to generations to come that this was the site where “Future Energy”—the Expo’s theme—originated.

In the 2013 competition for Expo 2017, other firms submitted proposals for temporary exhibit buildings that would be demolished after the fair. The AS+GG team (led by partners Adrian Smith, FAIA, Gordon Gill, FAIA, and Robert Forest, FAIA, LEED AP, and Director Alejandro Stochetti, AIA, LEED AP) saw the Expo as a catalyst for a new way of thinking about urban life and sustainable environment in this former Soviet bloc country.

A construction photo shows the progress on the sphere as of mid-January. Photo: Kiril Petrovsky.

A construction photo shows the progress on the sphere as of mid-January. Photo: Kiril Petrovsky.

Houston on the Steppes

Founded in 1830, Astana became the capital of Kazakhstan in 1997. Replete with government buildings (Parliament House, the Supreme Court, Ak Orda Presidential Palace), Nazerbayev University, and a modernist downtown marked by the 100-meter Kazakh Eli (“golden bird”) tower, Kazakhstan’s second-largest city (population 875,000) is “monumental but not very well planned for people, walkability, or human scale,” said AS+GG Project Manager Matt Dumich, AIA.

In their proposal, AS+GG emphasized the long-term potential of the three-month-long Expo. Phase 1 delineated the Expo’s site plan and buildings: the 3,000-person Congress Center; the hotel, amphitheatre, and central utility plant; four thematic pavilions, each devoted to a specific aspect of “Future Energy”; and art and performance spaces. Phase 2 encompassed their “legacy” as a “Third Industrial Revolution City,” borrowing Jeremy Rifkin’s term. The entire infrastructure would have new life after the Expo.

Parking and service areas would be converted to vibrant residential neighborhoods housing 4,000 families. The new community would be linked to downtown via buffered walkways. (Astana is the second-coldest capital city in the world, after Ulaanbaatar, Mongolia. The temperature can dip to -40˚C in winter.)

Exposition halls would be engineered to allow for an interstitial floor to be inserted post-Expo. This would make them functional as office spaces for high-tech companies and as science/R&D labs for the adjacent university. “The dean told us that having this technology hub would make it much easier for them to recruit students from Russia and the region,” said Stochetti.

The team took “Future Energy” to heart. As Senior Designer Anthony Viola, LEED AP, put it, “How could we reduce energy use in the buildings as much as possible, using the buildings themselves to contribute to passive strategies, before applying renewable systems to generate energy?”

The Minister of Environment Protection, Nurlan Kapparov, championed the AS+GG entry. “He saw this project as a prototype for the rest of the city,” said Dumich.

In October 2014, AS+GG beat out such heavy hitters as Coop Himmelb(l)au, HOK, Snøhetta, UNStudio, and Zaha Hadid Architects. As he accompanied the winning team to the airport for their flight, Kapparov mentioned that President Nazerbayev loved their proposal—but the Kazakhstan Pavilion would have to be a sphere.

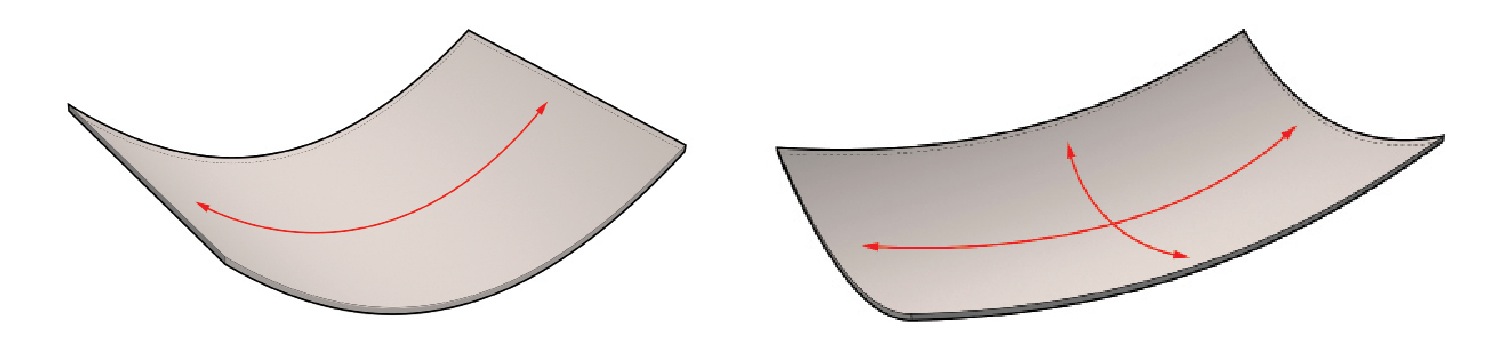

Forming a single-curved piece of glass with integrated PVs (above left) proved feasible, but bending glass containing integrated PVs to form a double curve (above right) turned out to be impractical.

Forming a single-curved piece of glass with integrated PVs (above left) proved feasible, but bending glass containing integrated PVs to form a double curve (above right) turned out to be impractical.

Making a ‘Smooth’ Sphere

In their submission, the AS+GG team proposed a main pavilion that resembled a giant yurt—the traditional nomadic tent of the region. Now they had to figure out how to build a sphere that conformed to the principles that had won them the competition.

One thing they didn’t want to do was design another flat-panel, geodesic dome. “We wanted a pure sphere, a smooth sphere—not faceted. It had to be fully curved,” said Stochetti. Each glass panel would have to be gently twisted and shaped in three dimensions. The sphere would also have to produce energy, which meant photovoltaics would have to be integrated into the glass.

AS+GG had used PV-integrated flat glass for the Federation of Korean Industries headquarters, in Seoul, and double-curved annealed glass—minus the PVs—for FKI’s adjacent conference center. But no one had integrated PVs into double-curved glass.

Over the course of a whirlwind 10-day tour of glass fabricators in 10 cities across Europe, the team got a crash course in why it is so difficult to do so.

One fabricator showed them a process in which PVs can be installed along with a polyvinyl butyral interlayer between two sheets of single-curved glass. Heat and pressure are applied to the materials to form a laminated unit. But because PVs are essentially black, they get hot when exposed to the sun and need to be installed in tempered glass. Otherwise, said Stochetti, “the heat differential between the glass in the PV area and the transparent area can shatter the glass.” Several fabricators were capable of producing single–curved tempered glass, but double–curved tempered glass has to be chemically strengthened.

Another fabricator said they could curve the tempered glass in one direction and force the second curvature through cold bending. “This would have been an easier option, but it would require the edges to be held by a continuous metal cap,” said Stochetti. “If you do that, you won’t see a smooth sphere.” Scratch that idea.

Two fabricators—Barcelona-based Cricursa, fabricator of the double-curved glass for the FKI convention center, and Sunglass srl, Padua, Italy—could make double-curved glass. The glass is heated in special ovens until the material is soft enough to take the form of a mold laying in the oven. Then the glass is cooled very slowly. The procedure, which can take 13-20 hours, yields double–curved annealed glass. But if you want to integrate PVs in annealed glass, you have to subject the assembly to a highly specialized chemical strengthening process that tempers it. Not an option.

Cricursa introduced them to a new technology that uses PV “beads” to form a frit-like surface on the glass. They determined that this method, while potentially reducing thermal stress, was still experimental. “We couldn’t wait for the technology to be commercially available at the scale we needed and still be on time,” said Stochetti.

A crew from general contractor Sembol Construction, Ankara, Turkey, at work on the Kazakhstan Pavilion. Temperatures in Astana, the second-coldest capital city in the world, can reach -40˚C. Photo: Kiril Petrovsky.

A crew from general contractor Sembol Construction, Ankara, Turkey, at work on the Kazakhstan Pavilion. Temperatures in Astana, the second-coldest capital city in the world, can reach -40˚C. Photo: Kiril Petrovsky.

Seeking Another Option

Their choices were starting to narrow. Should they ditch the dream of a “smooth” sphere and compromise on flat or single-curved glass with integrated PVs? That would look like Epcot Center redux. Should they forget about integrated PVs? How, then, would they meet the renewable energy goals for the pavilion? If not PVs, then what?

Well, what about wind? Could Astana’s steady, if brutal, southwest winds be turned into an asset? The AS+GG team turned once again to old friends at RWDI Consulting Engineers, Guelph, Ont., for their expertise in wind engineering and asked: Could the Kazakhstan Pavilion be transfigured into a giant wind-energy machine?

Maybe, replied the RWDI experts. The combined design team decided to test the idea of performing a kind of lobotomy on the sphere: By scooping out a gouge at the very top, wind could enter a channel on the interior skin, where it would be directed to energy-generating turbines.

“The wind studies were directed at finding out how much energy we could generate while balancing overall energy usage over a 40-year period,” said Viola. There were

tradeoffs. “If you add the cutout, you increase the surface area. In a place like Kazakhstan, every square meter you add to the exposed surface has the potential for a lot of thermal loss that can increase energy demand.” The cutout would also add to the cost of materials, total embodied energy, and construction time—all factors that had to be weighed in the modeling.

After numerous studies—a grinning Stochetti told me it seemed like “15 million” of them—AS+GG and RWDI optimized the shape for the cutout on the 25-story globe. They were even able to integrate PVs on the portion of the wind cutout with direct solar radiation, where flat or single-curved glass panels (with PVs) could be employed.

AS+GG delivered final documents to the general contractor, Sembol Construction, Ankara, Turkey, last March. As of mid-January, the structural steel frame was nearly topped out. The Expo buildings are all but fully clad in building integrated PVs.

Meanwhile, Sunglass srl is busily churning out 2,675 double-curved panels, totaling 18,225 sm. Because there are no PVs in the panels, Sunglass is fritting them to provide interior shading for visitors to the pavilion.

Not every detail of AS+GG’s master plan made the final cut. A pedestrian bridge over the highway between the site and the university will become a tunnel—not such a bad thing, considering the climate. The PV-clad residential buildings, rather than being oriented toward the southwest per AS+GG’s plan, have been sited on a rectilinear grid that reduces their ability to catch the sun’s rays.

So far, 60 countries (but not the U.S.) have pledged to exhibit. The doors open June 10, 2017, for three months.

Look for the sphere. You can’t miss it: it’s over 80 meters high.

Astana Expo City 2017, site of the “Future Energy” world’s fair in the capital of Kazakhstan. Rendering courtesy AS+GG.

Astana Expo City 2017, site of the “Future Energy” world’s fair in the capital of Kazakhstan. Rendering courtesy AS+GG.

Related Stories

| Nov 3, 2010

First of three green labs opens at Iowa State University

Designed by ZGF Architects, in association with OPN Architects, the Biorenewable Research Laboratory on the Ames campus of Iowa State University is the first of three projects completed as part of the school’s Biorenewables Complex. The 71,800-sf LEED Gold project is one of three wings that will make up the 210,000-sf complex.

| Nov 3, 2010

Park’s green education center a lesson in sustainability

The new Cantigny Outdoor Education Center, located within the 500-acre Cantigny Park in Wheaton, Ill., earned LEED Silver. Designed by DLA Architects, the 3,100-sf multipurpose center will serve patrons of the park’s golf courses, museums, and display garden, one of the largest such gardens in the Midwest.

| Nov 3, 2010

Public works complex gets eco-friendly addition

The renovation and expansion of the public works operations facility in Wilmette, Ill., including a 5,000-sf addition that houses administrative and engineering offices, locker rooms, and a lunch room/meeting room, is seeking LEED Gold certification.

| Nov 3, 2010

Sailing center sets course for energy efficiency, sustainability

The Milwaukee (Wis.) Community Sailing Center’s new facility on Lake Michigan counts a geothermal heating and cooling system among its sustainable features. The facility was designed for the nonprofit instructional sailing organization with energy efficiency and low operating costs in mind.

| Nov 3, 2010

Seattle University’s expanded library trying for LEED Gold

Pfeiffer Partners Architects, in collaboration with Mithun Architects, programmed, planned, and designed the $55 million renovation and expansion of Lemieux Library and McGoldrick Learning Commons at Seattle University. The LEED-Gold-designed facility’s green features include daylighting, sustainable and recycled materials, and a rain garden.

| Nov 3, 2010

Recreation center targets student health, earns LEED Platinum

Not only is the student recreation center at the University of Arizona, Tucson, the hub of student life but its new 54,000-sf addition is also super-green, having recently attained LEED Platinum certification.

| Nov 3, 2010

Senior housing will be affordable, sustainable

Horizons at Morgan Hill, a 49-unit affordable senior housing community in Morgan Hill, Calif., was designed by KTGY Group and developed by Urban Housing Communities. The $21.2 million, three-story building will offer 36 one-bed/bath units (773 sf) and 13 two-bed/bath units (1,025 sf) on a 2.6-acre site.

| Nov 3, 2010

Virginia biofuel research center moving along

The Sustainable Energy Technology Center has broken ground in October on the Danville, Va., campus of the Institute for Advanced Learning and Research. The 25,000-sf facility will be used to develop enhanced bio-based fuels, and will house research laboratories, support labs, graduate student research space, and faculty offices. Rainwater harvesting, a vegetated roof, low-VOC and recycled materials, photovoltaic panels, high-efficiency plumbing fixtures and water-saving systems, and LED light fixtures will be deployed. Dewberry served as lead architect, with Lord Aeck & Sargent serving as laboratory designer and sustainability consultant. Perigon Engineering consulted on high-bay process labs. New Atlantic Contracting is building the facility.

| Nov 3, 2010

Dining center cooks up LEED Platinum rating

Students at Bowling Green State University in Ohio will be eating in a new LEED Platinum multiuse dining center next fall. The 30,000-sf McDonald Dining Center will have a 700-seat main dining room, a quick-service restaurant, retail space, and multiple areas for students to gather inside and out, including a fire pit and several patios—one of them on the rooftop.

| Nov 2, 2010

A Look Back at the Navy’s First LEED Gold

Building Design+Construction takes a retrospective tour of a pace-setting LEED project.