Launched in June of 2012, UL Environment’s Zero Waste to Landfill, Virtually Zero Waste to Landfill, and Landfill Waste Diversion claim validations recognize companies that handle waste in innovative and environmentally responsible ways.

“We congratulate GAF on being the first to validate their tremendous waste reduction efforts at one of their largest manufacturing facilities. Their initiative, participation in the claim validation development process, and pursuit of the designation is exemplary and we hope this will galvanize other manufacturers to follow suit,” says Sara Greenstein, president of UL Environment. “We see more businesses undertaking waste reduction initiatives and the growing need for meaningful, third-party validation of landfill waste diversion claims. UL’s trusted Environmental Claim Validation mark helps manufacturers to promote this accomplishment clearly and confidently to their customers.”

UL Environment’s landfill waste diversion criteria include a variety of methods that companies may use to minimize the amount of waste they send to landfills, from energy creation through waste incineration to reuse, recycling, and composting. Companies that achieve a landfill diversion rate of 100 percent qualify for the Zero Waste to Landfill validation. Companies that achieve a diversion rate of 98 percent or greater qualify for the Virtually Zero Waste to Landfill validation. Those that achieve a diversion rate of 80 percent or greater qualify for the Landfill Waste Diversion validation.

“GAF has been committed to reducing manufacturing waste to zero for several years now, and we were actually internally certifying zero-waste plants," says Martin Grohman, director of sustainability at GAF. "However, third-party validation of environmental claims is increasingly important. There was no existing standard we could certify to. GAF has a long-standing relationship with UL, and when I presented this challenge to them, they took it on. All the way from the development of the standard to the desktop audit and the site visit, it has been a collaborative and constructive process. I’m especially proud of the efforts of our manufacturing team and their ongoing achievements on the journey to zero waste.”

The Mt. Vernon, Indiana plant, which spans 55,000 square feet and employs 40 people, achieved the certification. The specific claim is worded:

· GAF’s EverGuard TPO manufacturing facility, located in Mt. Vernon, IN, has achieved a landfill diversion rate of 90%.

To earn a Zero Waste to Landfill claim validation mark, a Virtually Zero Waste to Landfill claim validation mark, or a Landfill Waste Diversionclaim validation mark, companies must undergo an extensive, two-part, UL-led audit, which includes document evaluation and onsite visits. Each claim validation mark clearly indicates the facility’s specific rate of landfill diversion. Facilities whose landfill waste diversion claims have been validated by UL Environment are audited annually and featured in UL Environment’s Sustainable Products Database.

To learn more about UL Environment’s Zero Waste to Landfill, Virtually Zero Waste to Landfill, and Landfill Waste Diversion claim validations, visit www.ul.com/environment.

About UL Environment

UL Environment works to advance global sustainability, environmental health, and safety by supporting the growth and development of environmentally preferable products, services, and organizations. We help companies achieve their sustainability goals—and help purchasers, specifiers, retailers, governments, and consumers find products they can trust. UL Environment offers environmental claim validations, multi-attribute product certifications, environmental product declarations, indoor air quality certification, product emissions testing, organizational sustainability certification, and consulting. For more information, visit www.ul.com/environment.

About UL

UL is a premier global safety science company with more than 100 years of proven history. Employing nearly 9,000 professionals in 46 countries, UL is evolving the future of safety with five distinct business units – Product Safety, Environment, Life & Health, Verification, and Knowledge Services – to meet the expanding needs of customers and the global public. For more information on UL’s family of companies and network of 95 laboratory, testing, and certification facilities, go to UL.com.

About GAF

Founded in 1886, GAF has become the largest roofing manufacturer in North America. The company’s products include a comprehensive portfolio of steep-slope and commercial roofing systems, which are supported by an extensive national network of factory-certified contractors. Its success is driven by its commitment to Advanced Quality, Industry Expertise, and Solutions Made Simple for contractors, specifiers, and property owners alike. In 2011, GAF was the first roofing manufacturer to offer a Lifetime limited warranty on all of its laminated shingles and, in 2012, it introduced the GAF Lifetime Roofing System.

With a focus on social responsibility, GAF has developed Advanced Protection® Shingle Technology, which provides superior durability and wind resistance while reducing the use of scarce natural resources. The company has also developed single-ply and asphaltic membranes with superior durability and high reflectivity to meet the most rigorous industry standards while helping commercial property owners and designers reduce energy consumption.

Source:

Kate Rusnak

UL Environment

Email: Kate.rusnak@ul.com

###

Alyssa Hall

Marketing Communications

1361 Alps Road.

Wayne, NJ 07470

(P) 973-628-3301

Related Stories

Insulation | Oct 19, 2015

The expert’s guide to insulation materials

Even the best-designed envelopes can be undermined by thermal bridging in areas where insulation is deficient. Building envelope experts offers advice.

Building Enclosure Systems | Aug 11, 2015

Deriving value from coordinated building enclosure shop drawings

Building enclosure shop drawings play a critical role in guarding against common performance, cost, and schedule pitfalls associated with the transitions between adjacent enclosure components. Engineers with Simpson Gumpertz & Heger provide tips for success.

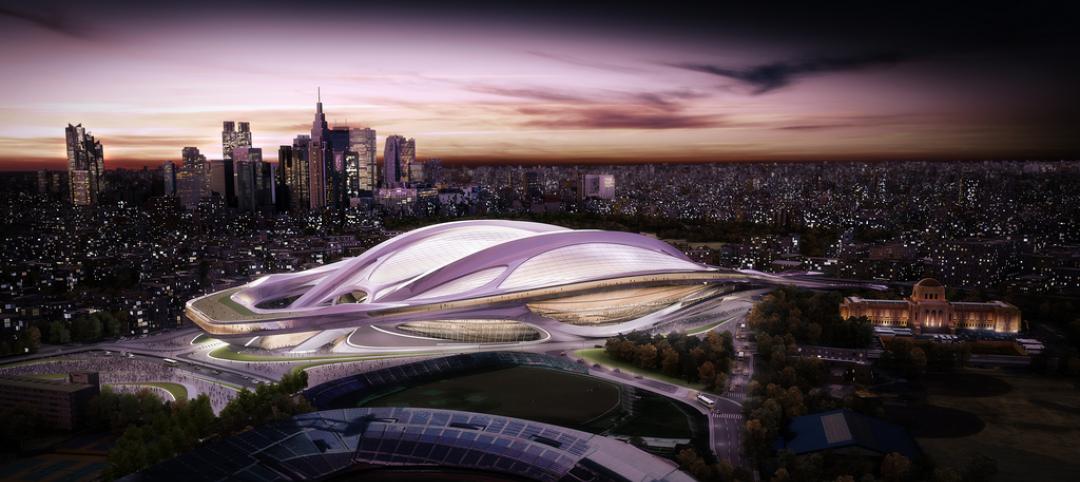

Sports and Recreational Facilities | Jul 23, 2015

Japan announces new plan for Olympic Stadium

The country moves on from Zaha Hadid Architects, creators of the original stadium design scrapped last week.

Sponsored | Building Enclosure Systems | Jul 20, 2015

Fire Rated Curtain Wall Performance in Dramatic Weather Conditions

Materials selected for the building envelope had to protect occupants from Wisconsin's weather, as well as ensuring their comfort.

Multifamily Housing | Mar 16, 2015

New Jersey Supreme Court puts control of affordable housing agency in the courts

The court said the state’s affordable housing agency had failed to do its job, and effectively transferred the agency's regulatory authority to lower courts.

Brick and Masonry | Feb 5, 2015

3D-printed 'cool brick' may provide cooling solution for arid locations

Cool Brick is made of porous ceramic bricks set in mortar. The bricks absorb water, which cools the air as it passes through the unit.

| Dec 28, 2014

Robots, drones, and printed buildings: The promise of automated construction

Building Teams across the globe are employing advanced robotics to simplify what is inherently a complex, messy process—construction.

Sponsored | | Nov 19, 2014

Fire resistive, blast-resistant glazing: Where security, safety, and transparency converge

Security, safety and transparency don’t have to be mutually exclusive thanks to new glazing technology designed to support blast and fire-resistant secure buildings. SPONSORED CONTENT

Sponsored | | Oct 29, 2014

What’s the difference between your building’s coating chalking and fading?

While the reasons for chalk and fade are different, both occurrences are something to watch for. SPONSORED CONTENT