As architectural teams continue to push the limit of building design with ever more complex geometries, engineering and construction firms must develop clever solutions to execute these daring schemes on time and within budget.

During the course of several recent projects, engineers with Simpson Gumpertz & Heger (SGH) and fabricator CW Keller have created an integrated approach to model, design, and off-site fabricate formwork for complex concrete geometries. The process combines SGH’s expertise with concrete materials, construction, and analysis of intricate assemblies, with CW Keller’s advanced modeling and computer numerically controlled (CNC) fabrication capabilities, to create geometrically complex, prefabricated formwork systems.

“The combination of advanced CNC machining and emerging technologies in construction materials is pushing the bounds of what can be cost-effectively constructed in concrete,” says Matthew Johnson, Principal with SGH. Johnson says the two disciplines—structural engineering and formwork fabrication—work hand in hand since the fabrication model can serve as the basis of analysis models. As a result, “teams can assess many options early and rapidly,” he says.

On the team’s most recent project, the new Gulf Stream Tank at the Patricia and Phillip Frost Museum of Science in Miami (pictured above), the prefab process saved roughly nine weeks of the project schedule compared with conventional site-constructed formwork. The elevated tank structure is 125-foot-diameter, conical, cast-in-place concrete construction. It will hold more than 500,000 gallons of seawater, and will feature an acrylic oculus to offer museum visitors views into the tank from below.

Also on the Building Team: Grimshaw (architect), Baker Concrete Construction (concrete subcontractor), Peri (shoring contractor), and Skanska (GC).

Photo: CW Keller

Photo: CW Keller

Photo: CW Keller

Photo: CW Keller

Rendering: Grimshaw

Rendering: Grimshaw

Related Stories

Great Solutions | Oct 3, 2019

REEF Technology wants to turn parking facilities into urban mobility hubs

The company currently operates 4,500 parking lots in 25 markets across North America.

Great Solutions | Aug 30, 2019

An ‘Internet of Beings’? Kinetic flooring promises more than just energy generation

Pavegen says its technology delivers a new level of human engagement in sustainability initiatives.

Great Solutions | Aug 7, 2019

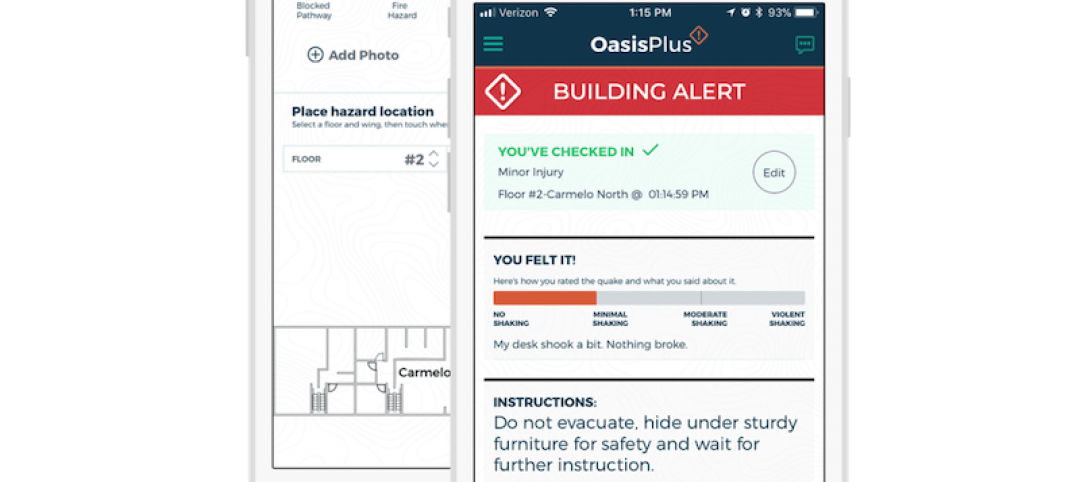

Earthquake response system takes the guesswork out of seismic safety

The platform provides real-time monitoring to help avoid unnecessary evacuations and improve emergency response.

Great Solutions | Jul 12, 2019

Smart sensor maintains privacy, enhances safety in sensitive spaces

The HALO IOT sensor is designed for use in places where cameras are not welcome.

Great Solutions | Apr 9, 2019

Raising the roof is cool again

Upbrella allows for floor-by-floor building construction that is, reportedly, safer and more productive than traditional methods.

Great Solutions | Mar 12, 2019

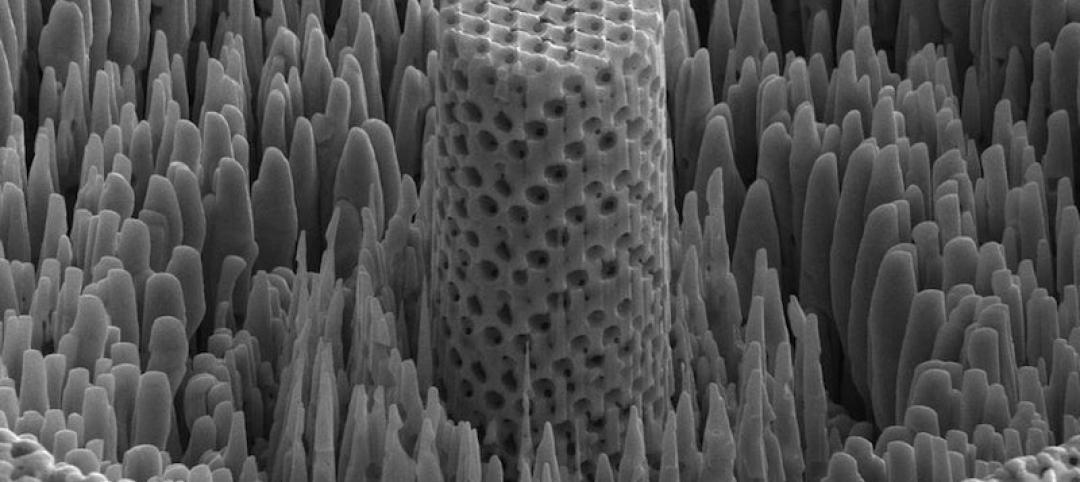

When is wood not really wood?

Inspired by the look and cellular nature of wood, researchers create 3D-printed “digital wood” and “metallic wood” that is as strong as titanium, with the density of water.

Sustainability | Feb 20, 2019

Studio NAB’s Superfarm project creates an entire ecosystem in an urban environment

The Superfarm will go beyond what vertical farms typically produce.

Great Solutions | Feb 7, 2019

An apiary for the sanctuary

A Seattle events venue, The Sanctuary, has a roof that is literally a hive of sustainability.

Great Solutions | Jan 2, 2019

Net zero construction trailer brings health and wellness to the jobsite

As AEC firms scramble to upgrade their offices to maximize occupant wellness and productivity, Pepper Construction asks, What about the jobsite office?

Great Solutions | Dec 12, 2018

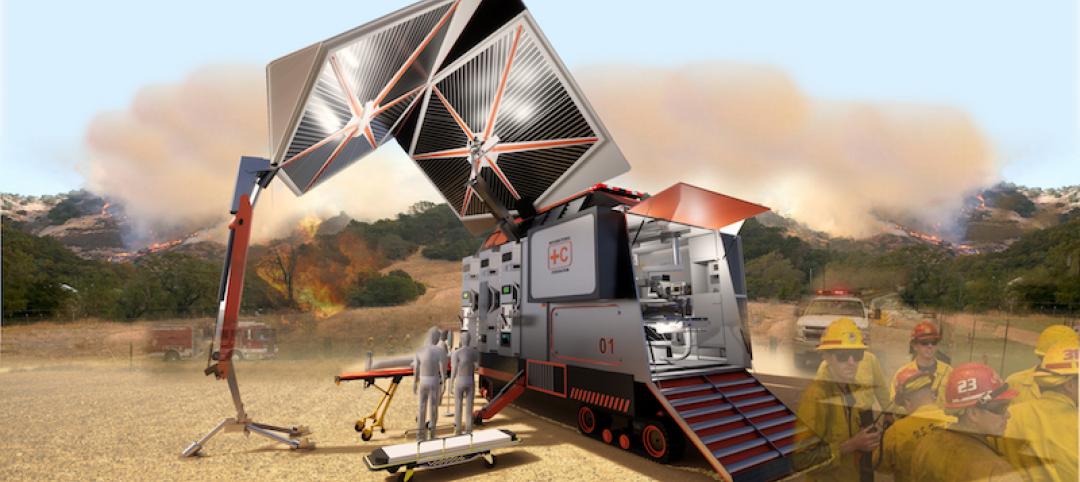

A modular, scalable mobile hospital can quickly respond to natural disasters and crises

CallisonRTKL’s design combines artificial intelligence, electric vehicle technology, and the latest in medical equipment.