As architectural teams continue to push the limit of building design with ever more complex geometries, engineering and construction firms must develop clever solutions to execute these daring schemes on time and within budget.

During the course of several recent projects, engineers with Simpson Gumpertz & Heger (SGH) and fabricator CW Keller have created an integrated approach to model, design, and off-site fabricate formwork for complex concrete geometries. The process combines SGH’s expertise with concrete materials, construction, and analysis of intricate assemblies, with CW Keller’s advanced modeling and computer numerically controlled (CNC) fabrication capabilities, to create geometrically complex, prefabricated formwork systems.

“The combination of advanced CNC machining and emerging technologies in construction materials is pushing the bounds of what can be cost-effectively constructed in concrete,” says Matthew Johnson, Principal with SGH. Johnson says the two disciplines—structural engineering and formwork fabrication—work hand in hand since the fabrication model can serve as the basis of analysis models. As a result, “teams can assess many options early and rapidly,” he says.

On the team’s most recent project, the new Gulf Stream Tank at the Patricia and Phillip Frost Museum of Science in Miami (pictured above), the prefab process saved roughly nine weeks of the project schedule compared with conventional site-constructed formwork. The elevated tank structure is 125-foot-diameter, conical, cast-in-place concrete construction. It will hold more than 500,000 gallons of seawater, and will feature an acrylic oculus to offer museum visitors views into the tank from below.

Also on the Building Team: Grimshaw (architect), Baker Concrete Construction (concrete subcontractor), Peri (shoring contractor), and Skanska (GC).

Photo: CW Keller

Photo: CW Keller

Photo: CW Keller

Photo: CW Keller

Rendering: Grimshaw

Rendering: Grimshaw

Related Stories

Great Solutions | Jul 9, 2021

MojoDesk creates a new solution for managing open office distractions

The MojoDome allows for a private work space while also maintaining a collaborative environment.

Great Solutions | Mar 18, 2021

Follow the leader: New following technology better equips robots for the jobsite

New proof-of-concept from Piaggio Fast Forward and Trimble enables robots and machines to follow humans.

Great Solutions | Feb 11, 2021

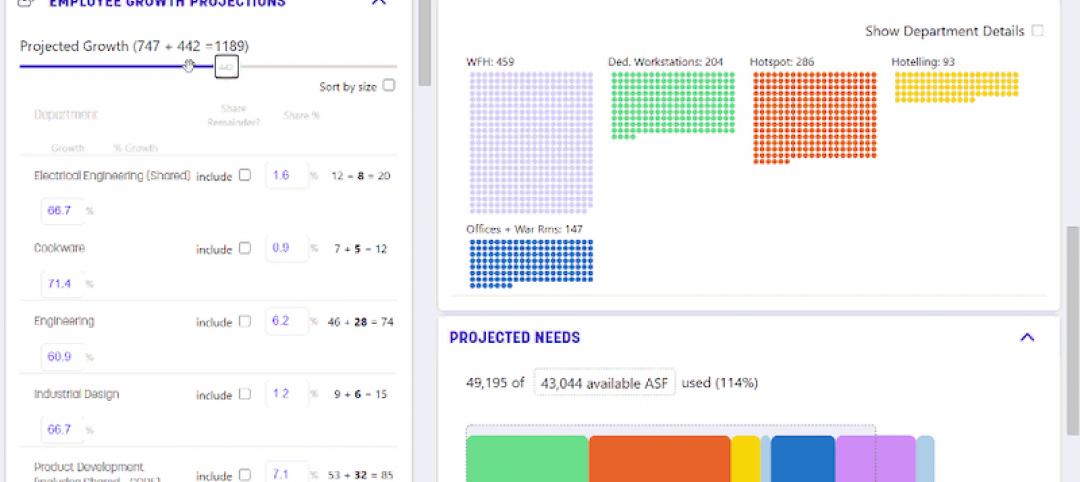

Simplifying the return to the office

A new web-based tool from Sasaki takes the guesswork out of heading back to the workplace.

Great Solutions | Oct 6, 2020

Could water-filled windows help buildings save energy?

New research shows how water-filled glass could help heat and cool buildings.

Great Solutions | Aug 10, 2020

From lobby to penthouse, elevators can be a 100% touch-free experience

The Toe-To-Go elevator system allows riders to operate the elevator entirely with their feet.

Great Solutions | Jul 13, 2020

Essential protection for businesses

Custom protective barriers help keep essential business employees safe.

Great Solutions | Apr 13, 2020

Family workstations highlight the new Fairfield Area Library

The workstations are the perfect remedy for squirming, restless children and toddlers.

Great Solutions | Feb 5, 2020

Power moves: The Shed

Precise positioning of mechanicals above its lighting keeps New York’s kinetic event space, The Shed, running.

Great Solutions | Dec 18, 2019

Robot uprising

Thyssenkrupp’s robotics interface platform helps robots use elevators like humans.

Great Solutions | Nov 12, 2019

Skanska designs personal protective equipment tailor-made for the female workforce

A safety vest is the first piece of equipment to undergo an update.