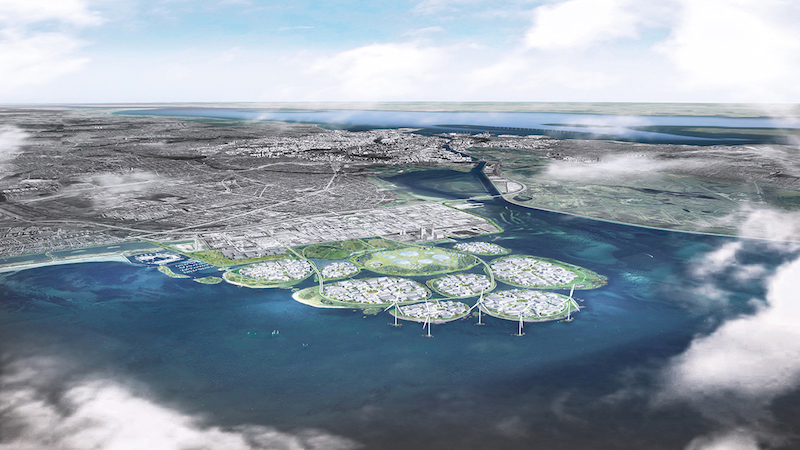

URBAN POWER, an architecture firm based in Denmark, has recently unveiled a plan to build nine islands that will be used for fossil-free energy production, act as a flood barrier, and add a publicly accessible nature area.

The land reclamation project, dubbed Holmene, will consist of nine industrial islands, each one surrounded by a “nature belt” that will include areas for sports as well as more tranquil areas for relaxation. Also included will be several small islets and reefs to provide new nature areas for plants and animals to thrive in the water and on land. The new islands will provide approximately 3.08 million sm of new space and will be built and developed stepwise to limit any impression of an unfinished project as construction progresses.

Courtesy URBAN POWER.

Courtesy URBAN POWER.

See Also: This is the country’s greenest academic building

Surplus soil from the regions building projects, such as its subway, will be used to create the islands. This surplus soil will also be used to create a natural protective landscape along the existing coastline, making it more resilient toward future flooding and providing an improved bike route.

Courtesy URBAN POWER.

Courtesy URBAN POWER.

The largest of the nine islands is reserved for the development of green technologies. It will be home to the largest waste-to-energy plant in Northern Europe. This plant will handle waste from the region’s 1.5 million citizens and turn it into clean water, resources, and biogas. When this waste-to-energy plant is combined with the heat storage, wind mills, and other green technologies across Holmene, an annual reduction of at least 70,000 tons of CO2 and production of more than 300,000 MWh fossil free energy can be achieved. This is equivalent to the power consumption of 25% of the population of Copenhagen.

The project is expected to be completed in 2040.

Courtesy URBAN POWER.

Courtesy URBAN POWER.

Courtesy Hvidovre kommune/URBAN POWER.

Courtesy Hvidovre kommune/URBAN POWER.

Related Stories

Codes and Standards | Jul 12, 2022

USGBC sets out principles for LEED’s future

The U.S. Green Building Council recently published a report containing principles outlining how LEED will evolve.

Building Team | Jul 12, 2022

10 resource reduction measures for more efficient and sustainable biopharma facilities

Resource reduction measures are solutions that can lead to lifecycle energy and cost savings for a favorable return on investment while simultaneously improving resiliency and promoting health and wellness in your facility.

Building Team | Jul 1, 2022

How to apply WELL for better design outcomes

The International WELL Building Institute (IWBI) cites attracting top talent, increasing productivity, and improving environmental, social or governance (ESG) performance as key outcomes of leveraging tools like their WELL Building Standard to develop healthier environments.

Green | Jun 22, 2022

The business case for passive house multifamily

A trio of Passive House experts talk about the true costs and benefits of passive house design and construction for multifamily projects.

Sustainable Design and Construction | Jun 14, 2022

For its new office, a farm in California considers four sustainable design options, driven by data

The architect used cove.tool’s performance measurement software to make its case.

Building Team | Jun 13, 2022

Partnership rethinks emergency shelters to turn them into sustainable, resilient homes

Holcim and the Norman Foster Foundation have struck a partnership to rethink emergency shelters to turn them into sustainable and resilient homes.

Green Specifications | May 12, 2022

MG2’s Sustainable Materials Evaluation System

Learn how MG2’s Sustainable Materials Evaluation System helps clients, prospects, and staff choose the most environmentally feasible materials for their building projects. Candon Murphy, LEED GA, Assoc. IIDA, Design Lab Manager and Materials & Sustainability Specialist with MG2, speaks with BD+C Executive Editor Rob Cassidy.

Sponsored | BD+C University Course | May 10, 2022

Design guide for parapets: Safety, continuity, and the building code

This course covers design considerations for parapets. The modern parapet must provide fire protection, serve as a fall-protective guard, transition and protect the roof/facade interface, conceal rooftop equipment, and contribute to the aesthetic character of the building.

Sponsored | BD+C University Course | May 5, 2022

Designing with architectural insulated metal wall panels

Insulated metal wall panels (IMPs) offer a sleek, modern, and lightweight envelope system that is highly customizable. This continuing education course explores the characteristics of insulated metal wall panels, including how they can offer a six-in-one design solution. Discussions also include design options, installation processes, code compliance, sustainability, and available warranties.