The Metal Building Manufacturers Association (MBMA) released a new guidebook, Metal Building Systems - Best Practices to Comply with Whole-Building Air Leakage Testing Requirements.

The free publication identifies procedures for metal building manufacturers and contractors to improve the ability of having metal buildings pass whole-building air leakage testing requirements.

“Whole-building air leakage testing is specified in the latest energy code updates,” says Tony Bouquot, MBMA general manager. “As more and more states and municipalities adopt these codes and testing requirements, this new guide will help manufacturers, builders, and owners to meet these demands by following some basic steps.”

Material from the guide was drawn from air leakage testing performed in the field, which has shown that certain parts of a building need special attention. These include:

- Dissimilar material interfaces, such as wall bases, doors, and windows

- Intersections/changes in air barrier configuration, including wall-to-roof interfaces, and wall corners

- Penetrations, including canopy framing members, mechanical (HVAC), electrical, and plumbing

The document includes detailed drawings and images, along with appendices that include a project checklist, overhead door specifics, and applicable codes, test methods, and material requirements.

Related Stories

Sponsored | Metals | Jul 20, 2015

Life cycle assessment, and why you should care

LCA is a way of quantifying the environmental impact generated by the manufacture and delivery of a product.

Sponsored | Metals | Jul 8, 2015

Metal Roof Retrofits: the potential, the problems, the payoff, part 2

During metal roof retrofits, look for moisture and check for asbestos

Sponsored | Metals | Jul 7, 2015

Cost efficient solution for confidence-boosting Camp For All

With donations as the charitable foundation's main source of income, camp facilities need to be affordable

Sponsored | Metals | Jun 30, 2015

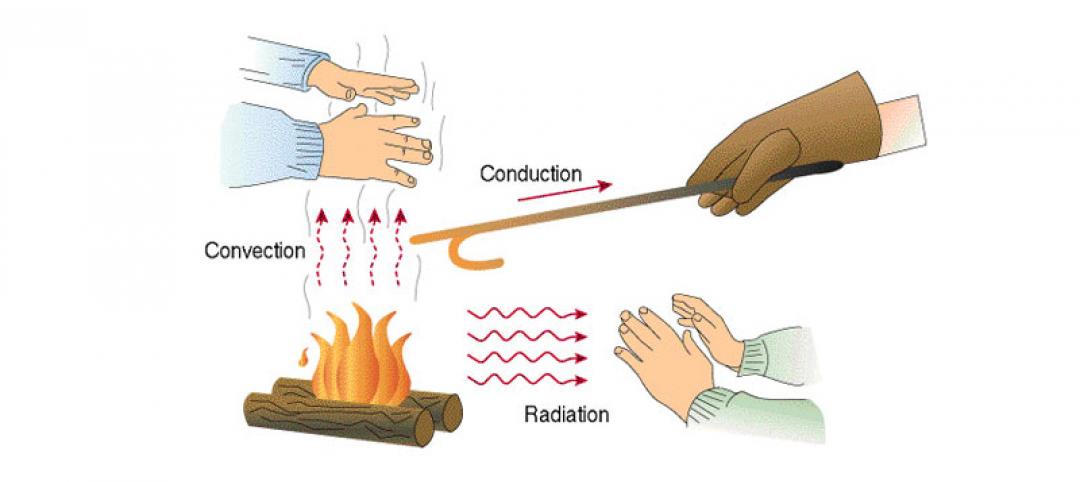

Understanding heat energy

Thermal convection occurs when hot molecules move from one location to another.

Sponsored | Metals | Jun 23, 2015

Metal Roof Retrofits: the potential, the problems, the payoff, part 1

For the best possible outcomes when working on metal roof retrofits, consider some simple but vital steps to get the best possible outcome from your retrofit job.

Sponsored | Metals | Jun 16, 2015

Metal building products deliver endless design freedom and sustainability

Numerous metal building products contain recycled content, reducing the need to mine new materials and saving space in landfills

Sponsored | Coatings | Jun 15, 2015

What’s in a coating, and why does it matter?

When the sun starts swinging punches at your building's coating, chalking and fading will start. But there's a way to prevent it.

Sponsored | Metals | Jun 9, 2015

How architects can tap into the expertise of their metal roof manufacturer, part 4

Let’s look at the importance of enforcing the detailed specifications the roof manufacturer provides.