BIG, together with Vestre, a Norwegian manufacturer or urban furniture, has unveiled designs for the world’s most sustainable furniture factory.

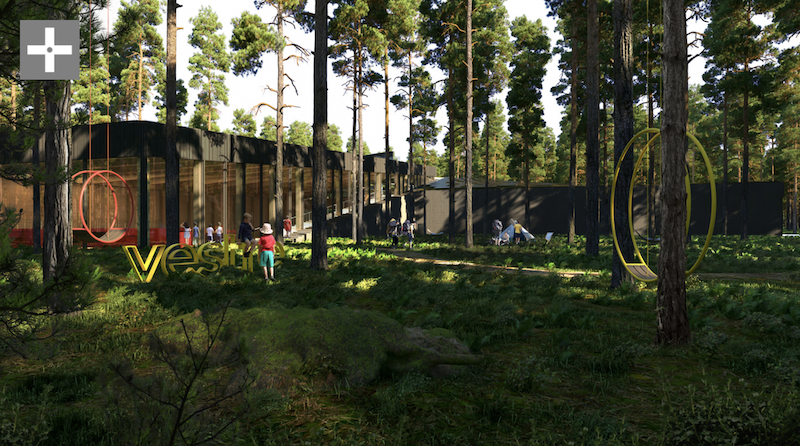

Dubbed The Plus, the project sits in the heart of the Norwegian forest and is envisioned as a village for a community dedicated to the cleanest, carbon neutral fabrication of urban and social furniture. The nearly 70,000-sf open production facility will double as a public 300-acre park for hiking and camping.

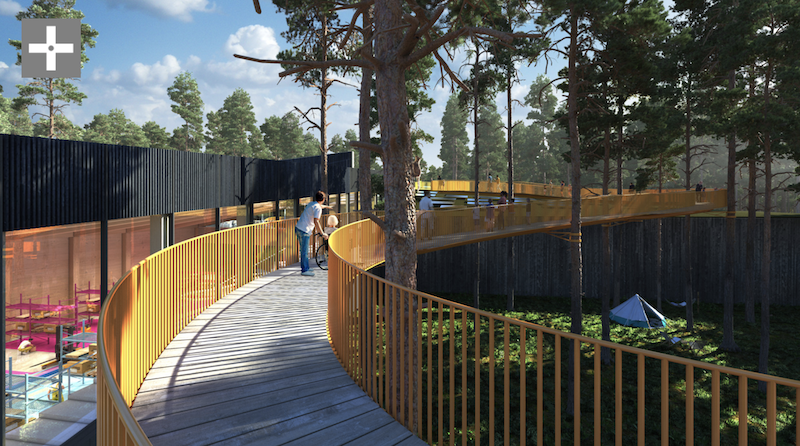

The project is conceived as a radial array of four main production halls – the warehouse, the color factory, the wood factory, and the assembly – that connect at the center, creating the ‘plus’ shape at the intersection. This layout will enable efficient, flexible, and transparent workflow between the manufacturing units. Each production unit will be built with a 21-meter free-spanning, CLT to create flexible, column-free spaces. Additionally, each wing will have one alternating ceiling corner lifted to create inclined roofs that allow views into the production halls and outside to the forest canopies.

See Also: The world’s first building made from carbon-fiber reinforced concrete starts construction in Germany

Located at the center of The Plus is the logistics office and exhibition center. The central hub wraps around a public, circular courtyard where the company’s latest outdoor furniture collections can be exhibited throughout the changing seasons. The plaza doubles as a panopticon for visitors and staff to view the factory’s production processes.

Visitors and staff can hike around the building on all four sides, concluding on the green roof terrace. An ADA-accessible ramp will allow wheelchairs and strollers along the path as well.

All building materials are being selected by their environmental impact; the facade will be built from local timber, low-carbon concrete, and recycled reinforcement steel. Every aspect of the design is based on principles of renewable and clean energy.

On the rooftop, 1,200 photovoltaic panels help power the factory. Excess heat from these panels is connected to an ice-water system for cooling, heat and cold storage tanks, heat pumps, and energy wells as a storage support system. The system contributes to at least 90% lower energy demand than that of a conventional factory.

The facility will ensure a minimum of 50% lower greenhouse gas emissions than comparable factories. Due to all of the sustainable design elements, The Plus will the first industrial building in the Nordic region to achieve BREAM Outstanding.

Smart robots, self-driving trucks, and a tablet to manage the entire factory will all be included. Each machine is assigned one of Vestre’s 200 colors, which will spill onto the floors and lead back into the central roundabout. The colorful mapping creates strong visual cues that help guide and explain the workflow of the facility, allowing visitors to easily follow the production process.

The project is currently in progress.

Related Stories

| Nov 5, 2012

Brasfield & Gorrie awarded new steel processing facility for Kloeckner Metals

The construction will take place on a 16-acre greenfield site at ThyssenKrupp Industrial Park in Calvert.

| Jun 1, 2012

New BD+C University Course on Insulated Metal Panels available

By completing this course, you earn 1.0 HSW/SD AIA Learning Units.

| May 29, 2012

Reconstruction Awards Entry Information

Download a PDF of the Entry Information at the bottom of this page.

| May 24, 2012

2012 Reconstruction Awards Entry Form

Download a PDF of the Entry Form at the bottom of this page.

| Apr 25, 2012

Bubble skyscraper design aims to purify drinking water

The Freshwater Skyscraper will address the issue of increasing water scarcity through a process known as transpiration

| Dec 19, 2011

Survey: Job growth driving demand for office and industrial real estate in Southern California

Annual USC Lusk Center for Real Estate forecast reveals signs of slow market recovery.

| Nov 22, 2011

Saskatchewan's $1.24 billion carbon-capture project

The government of Saskatchewan has approved construction of the Boundary Dam Integrated Carbon Capture and Storage Demonstration Project.

| Oct 3, 2011

Balance bunker and Phase III projects breaks ground at Mitsubishi Plant in Georgia

The facility, a modification of similar facilities used by Mitsubishi Heavy Industries, Inc. (MHI) in Japan, was designed by a joint design team of engineers and architects from The Austin Company of Cleveland, Ohio, MPSA and MHI.