Over the past several years, as building information modeling has gained widespread acceptance in the design and construction sector, Building Teams have become increasingly adept at representing buildings as data-rich 3D models, sometimes to the point of being able to integrate schedule (4D), cost (5D), and operations and maintenance information (6D) into their models.

BIM data is intended to be utilized in a continuum throughout the life cycle of a building: in design, to support visualization and development of construction documentation; through construction, for coordination and planning; and into facilities maintenance and operation, for the working life of the building.

Despite the tremendous investment in BIM by design and construction firms in the last few years, the industry has not capitalized on the use of BIM at the project site, where its direct access by field personnel could potentially have the greatest benefit on construction schedules and costs.

Most contractors’ use of BIM is limited to a project office adjacent to the actual job site where the building is being assembled; meanwhile, field personnel are still relying on abstract 2D drawings to perform all manner of critical tasks. In other words, BIM stops at the trailer door, and the richness of the information is lost to those who need it most. From layout to quality control, we should be leveraging BIM as the primary source of information on the project site.

MAKING THE LEAP OVER THE LAST 100 FEET

To address this problem, the industry has been developing several tools and techniques over the last decade to assist in bringing BIM data the “last 100 feet,” from the project trailer to the project site. These tools and processes to bring BIM to the field can lead to direct, measurable benefits related to cost, schedule, and quality of construction.

These include:

- 3D design models of construction details and assemblies

- Customized field drawings extracted from a coordinated BIM

- Automated survey layout directly from BIM geometry

- Ruggedized field tablets with BIM viewers

- “Augmented reality” technology to overlay BIM geometry onto the physical construction site

Of all the new technologies seeking to exploit BIM data out in the field, perhaps the most exciting is augmented reality, which enables the co-location of digital and physical data in a single medium. In the last decade, AR has become popular in gaming and media entertainment and on mobile devices. For the most part, though, its development for practical application in design and construction has lagged behind its adoption in other industries.

That situation is starting to change. Using hand-held projectors or ruggedized field tablets with special software to assist in tracking and registration, AR now enables the overlay of detailed, 3D BIM information onto the physical project site in real time and at full scale. With AR, field crews can now see the model in context without needing special skills to operate a computer or sophisticated BIM software.

In recent years, BNBuilders has been active in developing and applying AR tools in the construction industry; specifically, we are exploring how AR can successfully support common field tasks such as:

- Intuitive visualization of design models in context

- Layout and installation

- Quality control and inspections

- Illustrating the location of concealed work

- Commissioning and facilities operations and maintenance

THE CASE OF THE COMPLEX STAIR DESIGN

Working with our Building Team partner, architecture firm Perkins+Will, BNBuilders recently made use of augmented reality on the construction site in the design visualization, trade sequencing, and quality control of a set of architectural feature stairs in a laboratory tenant improvement for the Institute for Systems Biology, Seattle.

Using the design model we received from the architect as a background, we coordinated the complex detailing of the stairs by integrating models from the structural steel (MKE Detailing), glass (Herzog Glass), and railing detailers, along with models from the MEP subcontractors— Holaday-Parks, Auburn Mechanical, and VECA Electric & Technologies—and our own self-perform carpentry and layout information.

The complex nature of the stairs and its immediate context required unorthodox sequencing, in which field welds had to take place directly adjacent to already-installed feature glass. This led to intense study of the means and methods to solve the problem.

We used 4D visualization and augmented reality tools to plan and communicate the work with the labor crews. While the 4D visualization enabled us to study sequencing, the AR tools enabled the team to understand the proposed work in context, intuitively and at full scale. Craft workers could literally get their heads into a complex detail by simply walking around with a ruggedized tablet that overlaid co-located BIM geometry in real time, rather than being hampered by a mouse-and-keyboard interface to navigate a model at a desk remote from the site.

The value of AR to the project team was immediate. Thanks to AR technology, everyone involved with the project—the owner, the architect, the project engineers, the superintendent, the detailers, and the craft workers—was able to quickly grasp the proposed design intent and thereby gain the confidence and understanding needed to perform the work. In a complex project, where even the slightest layout or installation error could prove costly, the Building Team mitigated the risk and executed flawlessly using AR as a tool to get the richest set of BIM data in the hands of the people who needed it most.

NEXT STEPS FOR AUGMENTED REALITY

BNBuilders is one of a handful of forward-thinking AEC firms currently soliciting the assistance of software and hardware developers to improve the ease of use and practical application of AR on construction project sites, as well as lobbying those who develop BIM applications to integrate AR into their standard offerings.

For example, Vela Systems is working to put AR within the reach of field superintendents to enable simple field planning and verification of design. Field crews will be able to bring up the model of a specific location on an iPad; then, using the “Field BIM Interactive” module, they will be able to quickly confirm how design matches reality by orienting themselves so that the “virtual” world is superimposed on the physical one.

Rather than using off-the-shelf software, McCarthy Building Companies is pressing ahead with tools they have developed themselves. According to Connor Christian, the firm’s BIM manager, McCarthy expects to begin field testing its own internally developed AR tool later this year. “This exciting innovation will assist the construction and facilities crews in locating themselves within the building information model in real time and space,” says Christian.

Today, augmented reality is still largely experimental in construction, and prototype systems are not yet robust enough to allow widespread adoption on all project sites. But by continuing to develop, improve, and apply AR tools on pilot projects, this rapidly evolving technology can be made to work for the benefit of our entire industry.

It is possible that the next generation of augmented reality could completely revolutionize the way we construct our built environment, eliminating tape measures and paper plans. Eventually, AR could provide facility managers with the “ultimate stud finder” to leverage the BIM model in on-site facility operations and maintenance. +

Dace Campbell (dace.campbell@bnbuilders.com) is the Director of Innovation with BNBuilders, Seattle, where he manages IPD, BIM, and Lean across several offices. He has applied BIM to projects totaling $500 million, including two that have won AIA BIM awards. A member of the advisory board of the Lean Construction Institute, Cascadia Chapter, and the board of directors of the BuildingSMARTalliance and the Seattle BIM Forum, he was named a member of BD+C’s “40 Under 40” in 2011.

Related Stories

K-12 Schools | Apr 10, 2024

Surprise, surprise: Students excel in modernized K-12 school buildings

Too many of the nation’s school districts are having to make it work with less-than-ideal educational facilities. But at what cost to student performance and staff satisfaction?

Industrial Facilities | Apr 9, 2024

Confessions of a cold storage architect

Designing energy-efficient cold storage facilities that keep food safe and look beautiful takes special knowledge.

Cultural Facilities | Apr 8, 2024

Multipurpose sports facility will be first completed building at Obama Presidential Center

When it opens in late 2025, the Home Court will be the first completed space on the Obama Presidential Center campus in Chicago. Located on the southwest corner of the 19.3-acre Obama Presidential Center in Jackson Park, the Home Court will be the largest gathering space on the campus. Renderings recently have been released of the 45,000-sf multipurpose sports facility and events space designed by Moody Nolan.

Green | Apr 8, 2024

LEED v5 released for public comment

The U.S. Green Building Council (USGBC) has opened the first public comment period for the first draft of LEED v5. The new version of the LEED green building rating system will drive deep decarbonization, quality of life improvements, and ecological conservation and restoration, USGBC says.

Codes and Standards | Apr 8, 2024

Boston’s plans to hold back rising seawater stall amid real estate slowdown

Boston has placed significant aspects of its plan to protect the city from rising sea levels on the actions of private developers. Amid a post-Covid commercial development slump, though, efforts to build protective infrastructure have stalled.

Sustainability | Apr 8, 2024

3 sustainable design decisions to make early

In her experience as an architect, Megan Valentine AIA, LEED AP, NCARB, WELL AP, Fitwel, Director of Sustainability, KTGY has found three impactful sustainable design decisions: site selection, massing and orientation, and proper window-to-wall ratios.

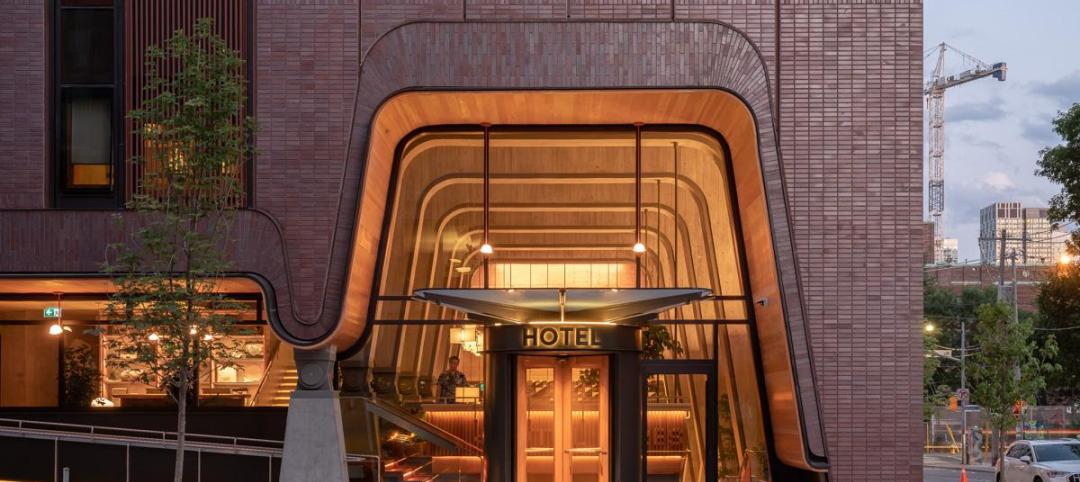

Brick and Masonry | Apr 4, 2024

Best in brick buildings: 9 projects take top honors in the Brick in Architecture Awards

The Ace Hotel Toronto, designed by Shim-Sutcliffe Architects, and the TCU Music Center by Bora Architecture & Interiors are among nine "Best in Class" winners and 44 overall winners in the Brick Industry Association's 2023 Brick in Architecture Awards.

Retail Centers | Apr 4, 2024

Retail design trends: Consumers are looking for wellness in where they shop

Consumers are making lifestyle choices with wellness in mind, which ignites in them a feeling of purpose and a sense of motivation. That’s the conclusion that the architecture and design firm MG2 draws from a survey of 1,182 U.S. adult consumers the firm conducted last December about retail design and what consumers want in healthier shopping experiences.

Healthcare Facilities | Apr 3, 2024

Foster + Partners, CannonDesign unveil design for Mayo Clinic campus expansion

A redesign of the Mayo Clinic’s downtown campus in Rochester, Minn., centers around two new clinical high-rise buildings. The two nine-story structures will reach a height of 221 feet, with the potential to expand to 420 feet.

Sports and Recreational Facilities | Apr 2, 2024

How university rec centers are evolving to support wellbeing

In a LinkedIn Live, Recreation & Wellbeing’s Sadat Khan and Abby Diehl joined HOK architect Emily Ostertag to discuss the growing trend to design and program rec centers to support mental wellbeing and holistic health.