During the coronavirus outbreak, wellness often took center stage in discussions about long-term infection control strategies.

Leo A Daly and Turner Construction have partnered on the development of a design-build concept called WorkWell™, an assembly of prefabricated components designed to allow employers, schools, venues, airports and public spaces to efficiently screen large groups of entrants for signs of infectious disease.

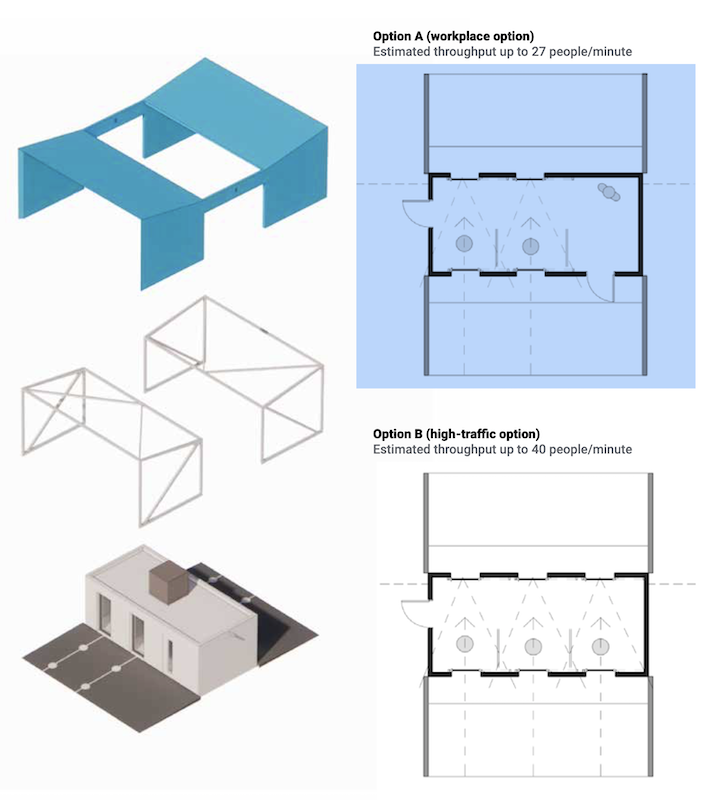

The WorkWell™ modular point of entry offers a safe and welcoming setting for health screening of individuals entering high-traffic buildings and public spaces. The centerpiece is the entry pavilion, installed in any area where a controlled checkpoint is needed. Individuals are quickly checked for fever and potentially screened for other health risk factors. The pavilion is designed for touchless operation and includes air handling systems capable of controlling the transfer of airborne pathogens.

“It’s important for that health screening be a pleasant and welcoming experience,” says Daniel Yudchitz, AIA, Senior Design Architect with Leo A Daly. “We designed WorkWell™ to be an enhancement to a facility, not an ordeal. It should inspire confidence in the health and safety of everyone entering.”

WorkWell's modular design is adjustable for different locations and levels of anticipated screening capacity.

PREFABRICATION SPEEDS INSTALLATION PROCESS

WorkWell™ modules are fabricated in an automated shop environment for speed of implementation, product quality and contractor safety. Design-build delivery enables the units to be deployed rapidly at a competitive price point. Offsite fabrication and plug-and-play design require minimal need for onsite construction crews.

“Prefabrication and modularization allow us to meet aggressive schedules while maintaining a high level of quality control and minimizing the potential for on-site safety incidents,” says Brian Knowles, LEED AP, DBIA, industrial executive at Turner Construction. “By deploying rapidly and at scale, we can keep workforces and the public healthy and facilities safely operational.”

The marketing campaign for WorkWell launched last Thursday. The product doesn’t have a specific client yet, but the development team is in discussions with several prospects.

The cost of each installation will depend on the application, options chosen, and features chosen. Knowles tells BD+C that, the expected range is from $260,000 to $320,000. “We are looking at six-to-nine weeks for full occupancy from date of confirmed order/scope.”

Related Stories

AEC Tech | Nov 12, 2020

The Weekly show: Nvidia's Omniverse, AI for construction scheduling, COVID-19 signage

BD+C editors speak with experts from ALICE Technologies, Build Group, Hastings Architecture, Nvidia, and Woods Bagot on the November 12 episode of "The Weekly." The episode is available for viewing on demand.

Coronavirus | Nov 9, 2020

Even now, marketing is not a four-letter word

As AEC firm leaders consider worst-case scenarios and explore possible solutions to surmount them, they learn to become nimble, quick, and ready to pivot as circumstances demand.

Coronavirus | Nov 5, 2020

Thornton Tomasetti releases 'Healthy Reentry' free software to aid safe office return

Open source app provides customizable health reporting and contact tracing capabilities.

Multifamily Housing | Oct 30, 2020

The Weekly show: Multifamily security tips, the state of construction industry research, and AGC's market update

BD+C editors speak with experts from AGC, Charles Pankow Foundation, and Silva Consultants on the October 29 episode of "The Weekly." The episode is available for viewing on demand.

Coronavirus | Oct 19, 2020

Flexible design helped the University of Kansas Strawberry Hill Behavioral Health Hospital adapt to the coronavirus

The University of Kansas Strawberry Hill Behavioral Health Hospital had been open for just over six months when it was faced with the global coronavirus pandemic.

Coronavirus | Oct 14, 2020

Altering facilities for a post-COVID-19 world

There are several possibilities when it comes to reconfiguring or adjusting a space to maintain the health and safety of workers, from reorganizing spaces to enable social distancing measures to full teardown and reconstruction of a plant.

Coronavirus | Oct 8, 2020

The Weekly show: Statue of Liberty Museum, emotional learning in K-12, LA's climate change vulnerability

The October 8 episode of BD+C's "The Weekly" is available for viewing on demand.

Coronavirus | Oct 7, 2020

AIA releases 3D models, strategies for reducing risk of COVID-19 in polling places

Awards program highlights trends in healthcare facility designs.

Coronavirus | Oct 2, 2020

With revenues drying up, colleges reexamine their student housing projects

Shifts to online learning raise questions about the value of campus residence life.