Last April, Dubai unveiled its 3D Printing Strategy, which calls for 25% of buildings in that city to be constructed using 3D printing technology by 2030. That strategy focuses on three major sectors: construction, medical products, and consumer products. The use of 3D printing in Dubai’s construction sector will increase by 2% starting in 2019.

One month after the strategy was publicized, Dubai completed what it asserts is the world’s first 3D-printed office, a 250-sm (2,691-sf) building made from a mixture of cement and other building materials, and assembled in 17 days by a 3D printer measuring 20 feet high, 120 feet long, and 40 feet wide, with a automated robotic arm.

Can a 3D-printed city be too far behind? The answer might lie in the Minitank, a 3D-printing crane under construction that its developer, a Silicon Valley startup called Cazza Construction Technologies, says can layer 2,153 sf of concrete per day, which would make it 50% faster than conventional construction methods.

Cazza’s 19-year-old CEO and co-founder Chris Kelsey tells CNN that construction is the natural progression for 3D printing. Last year, the Dubai Road and Transport Authority invited Cazza to present its technology to government officials overseeing the 3D Printing Strategy initiative. “Out of all of the groups they’d seen online or spoken with, they were most fascinated with the capabilities of our unique machines,” Kelsey told ConstructionWeekOnline.com.

It remains to be seen, though, whether this technology is practical for large-scale projects. There’s not much information about Cazza’s origins or its technology on its website, nor any images of the Minitank. (The site, however, is opening soliciting for partners and distributors for its technology.) Previously, Kelsey founded a company called Appsitude, an app development company. Part of Cazza’s funding came from proceeds of Appsitude’s sale last year.

Cazza, though, is undeniably following in the footsteps of pioneers who have tested the limits of 3D printing for construction. These include Behrokh Khoshnevis, a professor at the University of Southern California, who invented a concrete-extruding 3D printer in 2009 that could print a 2,500-sf structure in 20 hours; the construction firm WinSun, which in 2014 3D printed 10 one-story houses in a single day; and DUS Architects, which last year 3D printed a full canal house in Amsterdam.

Cazza’s process is relatively straightforward: an architect would upload blueprints onto a computer system, which transmits the information to the crane printer that layers the concrete in the shape of the design.

The Minitank, if it becomes operational, will be able to print on-site, and construct buildings up to three stories high. “The barrier to companies [printing on-site] so far has been that it’s extremely difficult to develop a machine with all of the factors needed,” Kelsey explained.

The Minitank would use cement made from 80% recycled materials. Cazza claims that its portable equipment can be set up within 30 minutes, and that its process would reduce labor and materials costs by up to 90%. Fernando De Los Rios, Cazza’s COO, said his company would soon bring its engineers from across the world to start working in Dubai and surrounding areas.

Dubai’s Roads and Transport Authority has several 3D printed projects in the works already, including the Museum of the Future, and DEWA’s labs in the Mohammed Bin Rashid Al-Maktoum Solar Park.

Related Stories

Giants 400 | Nov 14, 2022

4 emerging trends from BD+C's 2022 Giants 400 Report

Regenerative design, cognitive health, and jobsite robotics highlight the top trends from the 519 design and construction firms that participated in BD+C's 2022 Giants 400 Report.

Contractors | Nov 14, 2022

U.S. construction firms lean on technology to manage growth and weather the pandemic

In 2021, Gilbane Building Company and Nextera Robotics partnered in a joint venture to develop an artificial intelligence platform utilizing a fleet of autonomous mobile robots. The platform, dubbed Didge, is designed to automate construction management, maximize reliability and safety, and minimize operational costs. This was just one of myriad examples over the past 18 months of contractor giants turning to construction technology (ConTech) to gather jobsite data, manage workers and equipment, and smooth the construction process.

University Buildings | Nov 13, 2022

University of Washington opens mass timber business school building

Founders Hall at the University of Washington Foster School of Business, the first mass timber building at Seattle campus of Univ. of Washington, was recently completed. The 84,800-sf building creates a new hub for community, entrepreneurship, and innovation, according the project’s design architect LMN Architects.

Sponsored | Steel Buildings | Nov 7, 2022

Steel structures offer faster path to climate benefits

Faster delivery of buildings isn’t always associated with sustainability benefits or long-term value, but things are changing. An instructive case is in the development of steel structures that not only allow speedier erection times, but also can reduce embodied carbon and create durable, highly resilient building approaches.

Mass Timber | Aug 30, 2022

Mass timber construction in 2022: From fringe to mainstream

Two Timberlab executives discuss the market for mass timber construction and their company's marketing and manufacturing strategies. Sam Dicke, Business Development Manager, and Erica Spiritos, Director of Preconstruction, Timberlab, speak with BD+C's John Caulfield.

Green | Jul 26, 2022

Climate tech startup BlocPower looks to electrify, decarbonize the nation's buildings

The New York-based climate technology company electrifies and decarbonizes buildings—more than 1,200 of them so far.

Building Technology | Jun 9, 2022

GSA Green Proving Ground program selects six innovative building technologies for evaluation

The U.S. General Services Administration’s (GSA) Green Proving Ground program, in collaboration with the U.S. Department of Energy, has selected six innovative building technologies for evaluation in GSA’s inventory.

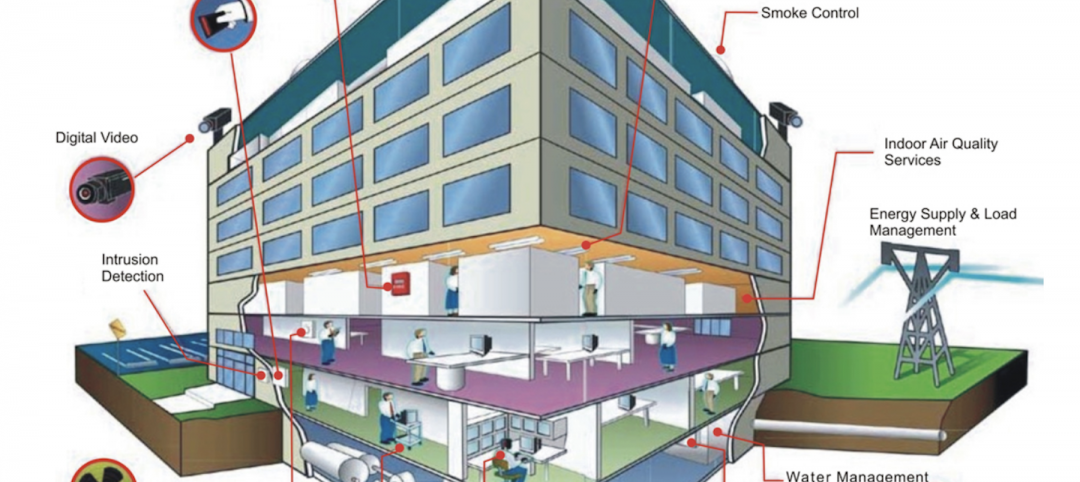

Smart Buildings | Jun 1, 2022

Taking full advantage of smart building technology

Drew Deatherage of Crux Solutions discusses where owners and AEC firms could do better at optimizing smart technology in building design and operations.

Sponsored | BD+C University Course | May 10, 2022

Design guide for parapets: Safety, continuity, and the building code

This course covers design considerations for parapets. The modern parapet must provide fire protection, serve as a fall-protective guard, transition and protect the roof/facade interface, conceal rooftop equipment, and contribute to the aesthetic character of the building.

Sponsored | BD+C University Course | May 10, 2022

Designing smarter places of learning

This course explains the how structural steel building systems are suited to construction of education facilities.