Steel and concrete manufacturers and their trade groups oppose changes in U.S. building codes that would allow mass timber for tall buildings. Their arguments center on fire safety, strength, and durability, while making the case for the environmental benefits of their products.

The American Institute of Steel Construction contends that the steel industry is a “world leader” in using recycled material and end-of-life recycling, and has made strides to lower greenhouse gas emissions below regulatory requirements. At a webinar on resilience in November, the National Ready-Mix Concrete Association and the MIT Concrete Sustainability Hub presented research which claimed that enhanced concrete design is more cost- and energy-efficient than non-engineered wood design.

Concrete and steel both beat mass timber on price, although that advantage is narrowing. StructureCraft Builders’ Lucas Epp says that by using nail laminated timber, the Building Team got construction costs for T3, in Minneapolis, to within 5% of steel.

Paul Fast, of Fast + Epp, says his team got the cost of Brock Commons, at the University of British Columbia, “very close to the price of using concrete.” He concedes that wood construction “groans on the cost front” for buildings with bigger apartments or wider interior spans. In markets like Washington, D.C., where building with concrete is relatively cheap, “wood has less hope,” he says.

Prices should come down as new innovations emerge. Freres Lumber Co., Lyons, Ore., is refining its new product, mass plywood panels, as a lower-cost alternative to CLT. MPPs require 20–30% less wood because they use engineered veneer and custom plywood layups as base materials. The panels can be fabricated in sizes up to 12x48 feet, and in thicknesses up to two feet.

Related Stories

Multifamily Housing | Apr 23, 2018

Mass timber design for multifamily housing

The adaptability of urban development could be revolutionized through the inherent strength of mass timber construction.

Wood | Feb 15, 2018

Japanese company announces plans for the world’s tallest wooden skyscraper

The planned tower would rise 350 meters (1148 feet).

Wood | Feb 5, 2018

The largest timber office building in the U.S. will anchor Newark, N.J. mixed-use development

Michael Green Architecture is designing the building.

Multifamily Housing | Jan 4, 2018

Shigeru Ban’s mass timber tower in Vancouver gets city approval

The 232-foot-tall Terrace House luxury condo development will be the tallest hybrid wood structure in North America.

Sports and Recreational Facilities | Dec 18, 2017

Canada’s newest funicular makes Edmonton’s largest green space more accessible

The incline elevator is located in downtown Edmonton and was publicly funded.

Wood | Nov 30, 2017

The first large-scale mass timber residence hall in the U.S. is under construction at the University of Arkansas

Leers Weinzapfel Associates, Modus Studio, Mackey Mitchell Architects, and OLIN collaborated on the design.

Codes and Standards | Nov 15, 2017

U.S. finalizes tariffs on Canadian softwood lumber

The duties would add 20% or more to cost if trade negotiators can’t find common ground.

Sponsored | Wood | Oct 24, 2017

Multifamily framers recommend AdvanTech® products for flat, even flooring base

With lengthy exposure time, reliably stiff, moisture-resistant subflooring is key in reducing risk of delays.

Green | Aug 11, 2017

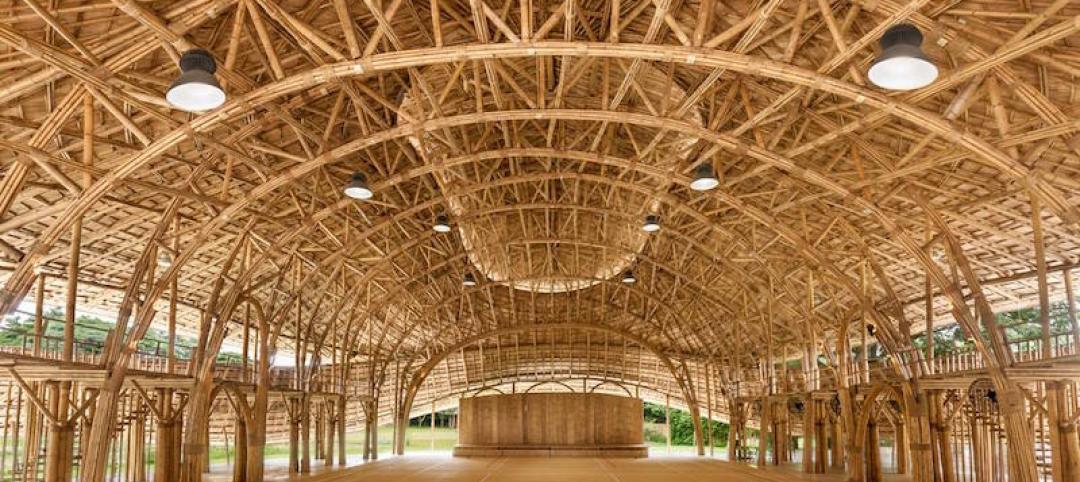

A school’s sports hall is created entirely from bamboo

The building boasts a zero-carbon footprint and is naturally ventilated.

Codes and Standards | Jul 27, 2017

Five fire scenarios tested on full-scale mass timber building

Results will help inform code changes.