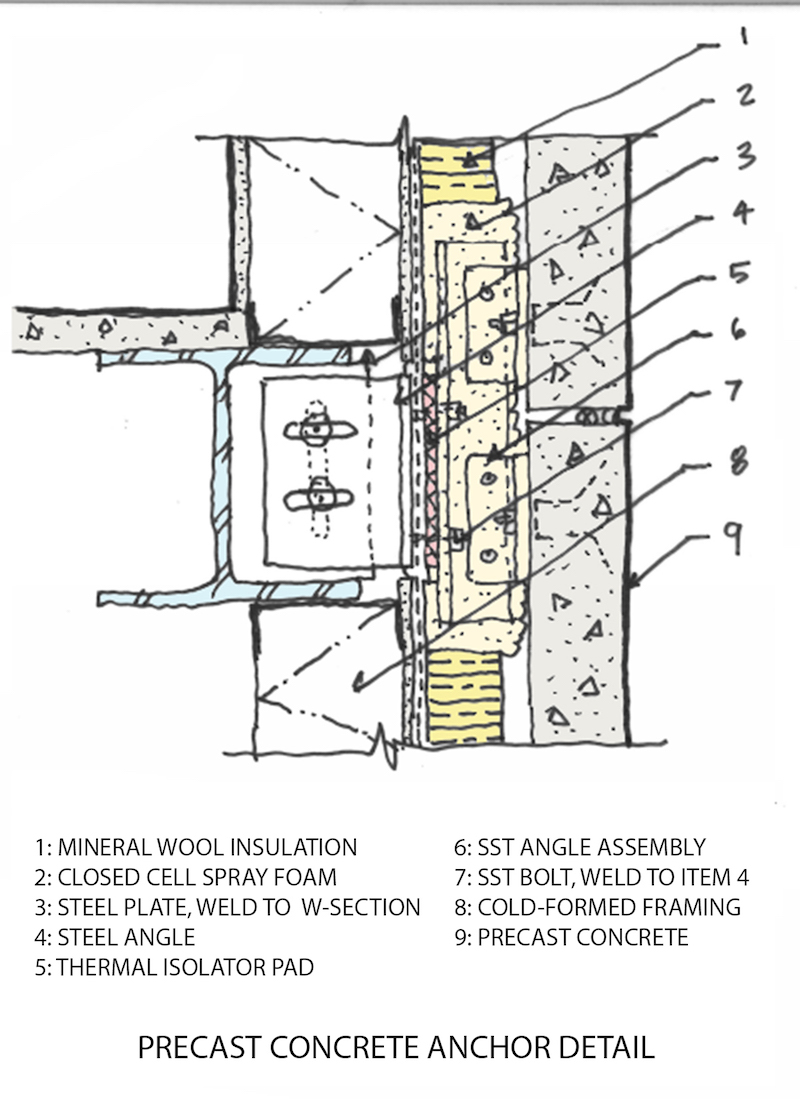

Building Teams value the versatility of precast concrete exterior wall construction, but, like any cladding approach, it has its drawbacks. Conventionally used, precast panels form the weather barrier system, with the vapor barrier and insulation located on the interior face. This primary barrier system can become compromised over time for a number of reasons, such as the short effective life of sealants.

To solve this weather barrier breakdown issue, three architects from Sasaki Associates—Brad Prestbo, AIA, Senior Associate; Gerard Gutierrez, AIA, CDT, Director of Technical Resource Group; and Jeff Benea, Associate—developed a simple yet novel anchor detail that maintains air/water/vapor barrier integrity and continuous insulation, similar to cavity wall construction, while still harnessing the versatility of precast panels.

The detail uses back-to-back angles. The interior set of angles is attached to the superstructure—once in place, the air/water/vapor barrier can be applied. The exterior set of angles can then be installed, sandwiching the air/water/vapor barrier.

Panels can be hung or gravity loaded onto the structural frame. Depending on panel layout, anchor access can be made from panel jambs or head.

Since developing the system, Sasaki has deployed it in several hundred thousand square feet of cladding.

Illustration: Sasaki Architects

Illustration: Sasaki Architects

Related Stories

Great Solutions | Jan 7, 2016

Bacteria-killing paint and magnetic wallcovering highlight innovations in surface materials

Sherwin-Williams recently introduced Paint Shield, the first EPA-registered microbicidal paint that kills virtually all infection-causing bacteria after two hours of exposure on painted surfaces.

Great Solutions | Jan 6, 2016

Shepley Bulfinch develops elegant design solution to address behavioral issues in emergency departments

ED scheme allows staff to isolate unruly patients and visitors in a secure area.

Great Solutions | Jan 6, 2016

All-encompassing farming kit can provide communities with a sustainable food supply

Several manufacturers partnered with the group Farm from a Box to develop an off-the-grid farming solution for communities, all without the need for outside help.

Great Solutions | Jan 4, 2016

Toronto’s newest hospital employs 10 robots for moving food, supplies, and equipment

The 1.8 million-sf Humber River Hospital is loaded with high-tech gadgets. Its coolest innovation is the use of automated guided vehicles.

Great Solutions | Jan 4, 2016

Snoozebox’s portable hotel rooms make outside events more livable

Since 2011, the London-based company has thrived by creating portable hotels that are set up for the duration of open-air events (or longer), and offer many of the comforts of conventional hotels.