Clemson University has been in the spotlight for the past few months thanks to its thrilling BCS National Championship win. But that doesn’t mean other departments within the university aren’t pulling their weight, too.

Clemson’s School of Architecture has recently received attention for its new framing method: the Sim[PLY] Framing System. The system is created from locally sourced plywood and uses a computer numeric control (CNC) fabricator to cut the components. After being pre-cut and pre-measured, the framing can be flat-packed for shipment, which allows for the use of small transport vehicles.

Beyond the sustainability and transportation benefits, Sim[PLY] provides strong thermal performance. “The wall cavity depth can be easily scaled up or down, for greater or less insulating value, as needed,” says Dustin Albright, Assistant Professor, Clemson School of Architecture. “Moreover, Sim[PLY] walls have minimal thermal bridging compared to inline framing. These measures would otherwise require offset studs or Larsen truss construction, if using conventional lumber.”

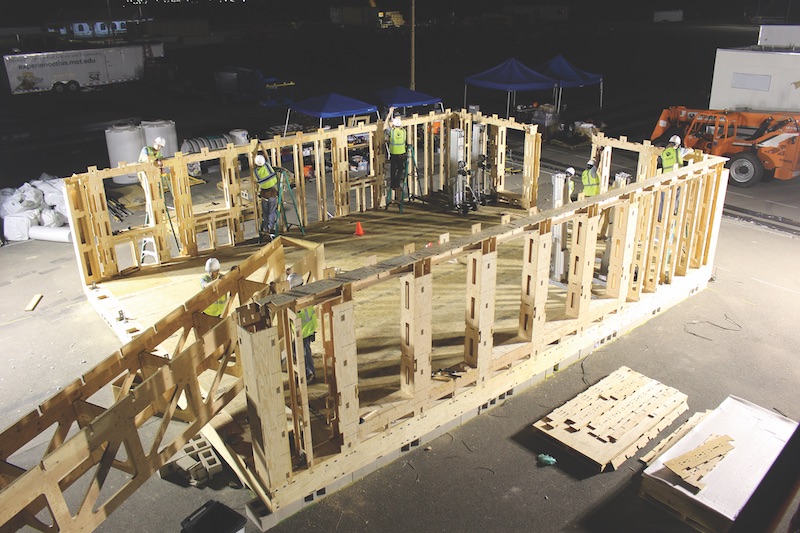

The base of a Sim[PLY] Framing System wall prior to standing it. This wall was part of the initial prototype of the Indigo Pine House, Clemson’s 2015 Solar Decathlon entry. Courtesy Clemson University School of Architecture.

The base of a Sim[PLY] Framing System wall prior to standing it. This wall was part of the initial prototype of the Indigo Pine House, Clemson’s 2015 Solar Decathlon entry. Courtesy Clemson University School of Architecture.

What is really helping to set Sim[PLY] apart from other prefabricated structures is how it is put together. Thanks to a patent-pending interlocking tab-and-slot connection method, the structure can be assembled by unskilled labor without the use of power tools or nails. All that is required to build the structure are steel zip ties and screws.

The connection system means assembling the structure is similar to building a 3D puzzle, and because no nails are used, the system can be disassembled just as easily as it is assembled, without causing any structural damage.

“Non-destructive disassembly involves snipping the cable ties and popping the joints loose with a

mallet. The pieces are then ready to flat-pack and reuse elsewhere,”

says Albright.

Sim[PLY] was used to build CropStop in Greenville, S.C., an incubator kitchen and gathering place that allows crop owners to process their harvests to meet local demand for farm-to-table foods. Albright says Sim[PLY] is “gathering interest” from CropStop partners in Florida, as well.

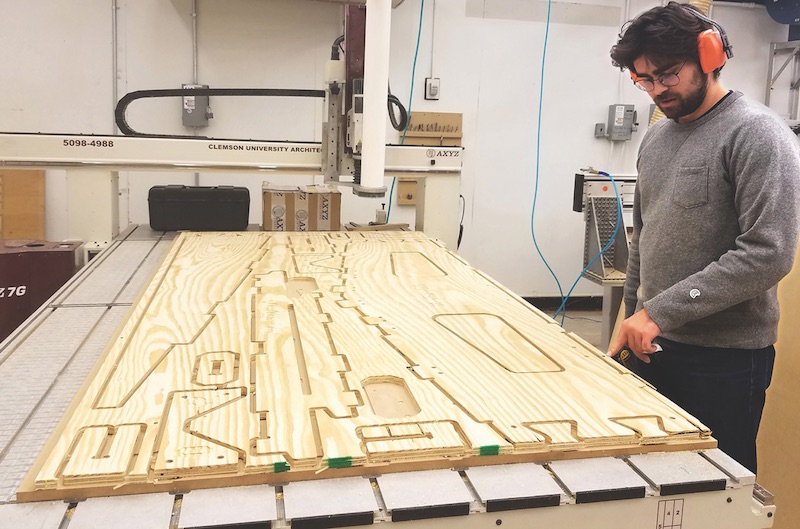

Clemson architecture student Paul Mosher cuts components for a full-scale mockup. Courtesy Clemson University School of Architecture.

Clemson architecture student Paul Mosher cuts components for a full-scale mockup. Courtesy Clemson University School of Architecture.

Related Stories

Cladding and Facade Systems | Apr 5, 2023

Façade innovation: University of Stuttgart tests a ‘saturated building skin’ for lessening heat islands

HydroSKIN is a façade made with textiles that stores rainwater and uses it later to cool hot building exteriors. The façade innovation consists of an external, multilayered 3D textile that acts as a water collector and evaporator.

Transportation & Parking Facilities | Mar 23, 2023

Amsterdam debuts underwater bicycle parking facility that can accommodate over 4,000 bikes

In February, Amsterdam saw the opening of a new underwater bicycle parking facility. Located in the heart of the city—next to Amsterdam Central Station and under the river IJ (Amsterdam’s waterfront)—the facility, dubbed IJboulevard, has parking spots for over 4,000 bicycles, freeing up space on the street.

Concrete | Jan 24, 2023

Researchers investigate ancient Roman concrete to make durable, lower carbon mortar

Researchers have turned to an ancient Roman concrete recipe to develop more durable concrete that lasts for centuries and can potentially reduce the carbon impact of the built environment.

Sponsored | Resiliency | Dec 14, 2022

Flood protection: What building owners need to know to protect their properties

This course from Walter P Moore examines numerous flood protection approaches and building owner needs before delving into the flood protection process. Determining the flood resilience of a property can provide a good understanding of risk associated costs.

Giants 400 | Nov 14, 2022

4 emerging trends from BD+C's 2022 Giants 400 Report

Regenerative design, cognitive health, and jobsite robotics highlight the top trends from the 519 design and construction firms that participated in BD+C's 2022 Giants 400 Report.

AEC Tech | Apr 13, 2022

A robot automates elevator installation

Schindler—which manufactures and installs elevators, escalators, and moving walkways—has created a robot called R.I.S.E. (robotic installation system for elevators) to help install lifts in high-rise buildings.

AEC Tech Innovation | Mar 9, 2022

Meet Emerge: WSP USA's new AEC tech incubator

Pooja Jain, WSP’s VP-Strategic Innovation, discusses the pilot programs her firm’s new incubator, Emerge, has initiated with four tech startup companies. Jain speaks with BD+C's John Caulfield about the four AEC tech firms to join Cohort 1 of the firm’s incubator.

Great Solutions | Jan 18, 2022

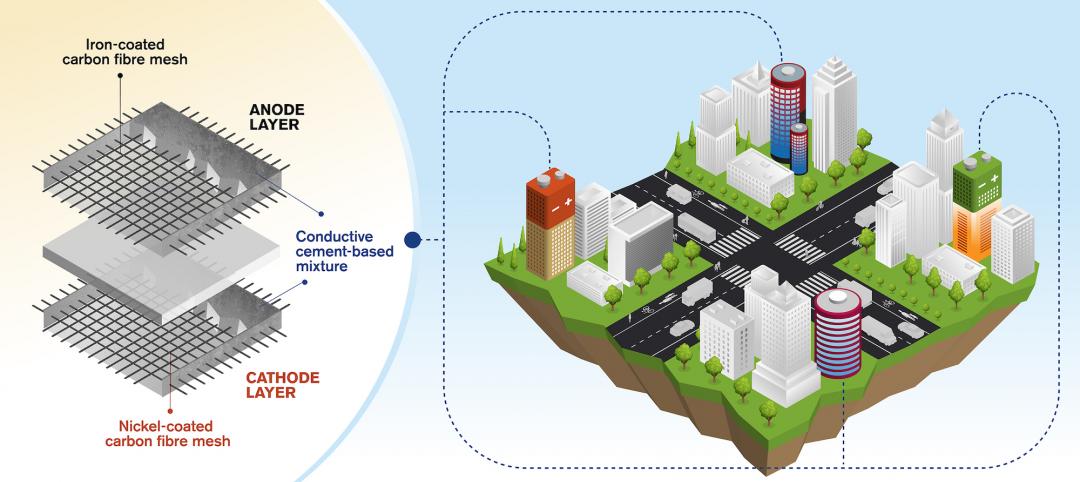

Researchers develop concept for rechargeable cement-based batteries

Researchers from the Department of Architecture and Civil Engineering at Chalmers University of Technology in Gothenburg, Sweden, have created a concept for rechargeable batteries made of cement. The concept involves a cement-based mixture with small amounts of short carbon fibers added to increase conductivity and flexural toughness.

Great Solutions | Nov 22, 2021

Drywall robots take the risk out of the finishing process

Canvas is using robots to complement the work already being done by drywall professionals.

Great Solutions | Sep 23, 2021

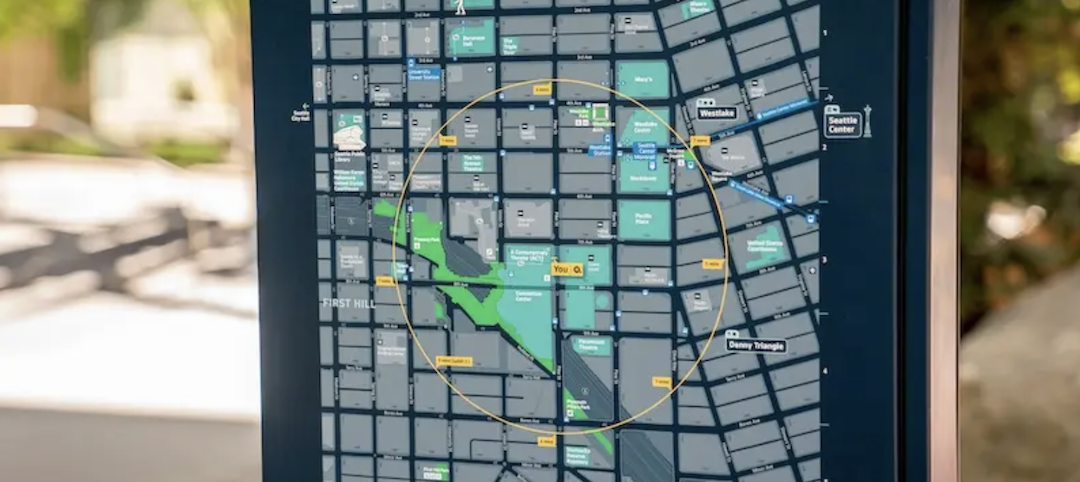

Seattle looks to become America’s most walkable city with a new citywide wayfinding system

Seamless Seattle will support the Seattle Department of Transportation’s commitment to increase the percentage of trips made by walking to 35% by 2035.