Clemson University has been in the spotlight for the past few months thanks to its thrilling BCS National Championship win. But that doesn’t mean other departments within the university aren’t pulling their weight, too.

Clemson’s School of Architecture has recently received attention for its new framing method: the Sim[PLY] Framing System. The system is created from locally sourced plywood and uses a computer numeric control (CNC) fabricator to cut the components. After being pre-cut and pre-measured, the framing can be flat-packed for shipment, which allows for the use of small transport vehicles.

Beyond the sustainability and transportation benefits, Sim[PLY] provides strong thermal performance. “The wall cavity depth can be easily scaled up or down, for greater or less insulating value, as needed,” says Dustin Albright, Assistant Professor, Clemson School of Architecture. “Moreover, Sim[PLY] walls have minimal thermal bridging compared to inline framing. These measures would otherwise require offset studs or Larsen truss construction, if using conventional lumber.”

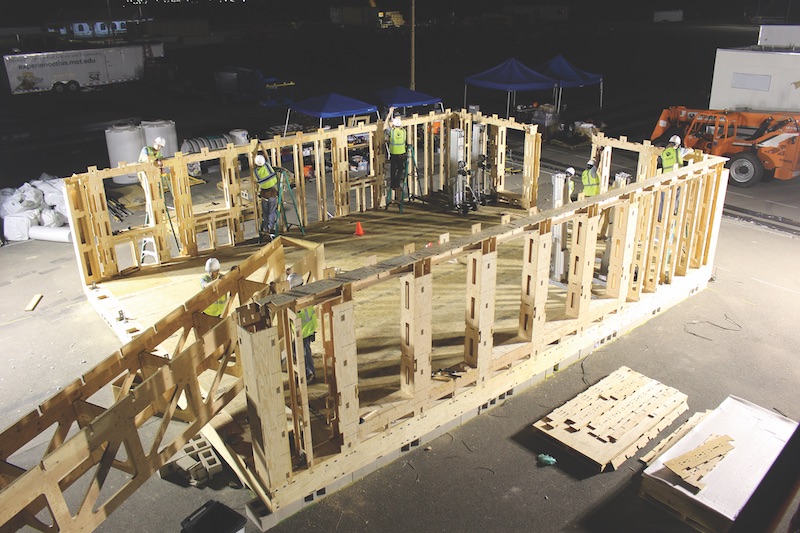

The base of a Sim[PLY] Framing System wall prior to standing it. This wall was part of the initial prototype of the Indigo Pine House, Clemson’s 2015 Solar Decathlon entry. Courtesy Clemson University School of Architecture.

The base of a Sim[PLY] Framing System wall prior to standing it. This wall was part of the initial prototype of the Indigo Pine House, Clemson’s 2015 Solar Decathlon entry. Courtesy Clemson University School of Architecture.

What is really helping to set Sim[PLY] apart from other prefabricated structures is how it is put together. Thanks to a patent-pending interlocking tab-and-slot connection method, the structure can be assembled by unskilled labor without the use of power tools or nails. All that is required to build the structure are steel zip ties and screws.

The connection system means assembling the structure is similar to building a 3D puzzle, and because no nails are used, the system can be disassembled just as easily as it is assembled, without causing any structural damage.

“Non-destructive disassembly involves snipping the cable ties and popping the joints loose with a

mallet. The pieces are then ready to flat-pack and reuse elsewhere,”

says Albright.

Sim[PLY] was used to build CropStop in Greenville, S.C., an incubator kitchen and gathering place that allows crop owners to process their harvests to meet local demand for farm-to-table foods. Albright says Sim[PLY] is “gathering interest” from CropStop partners in Florida, as well.

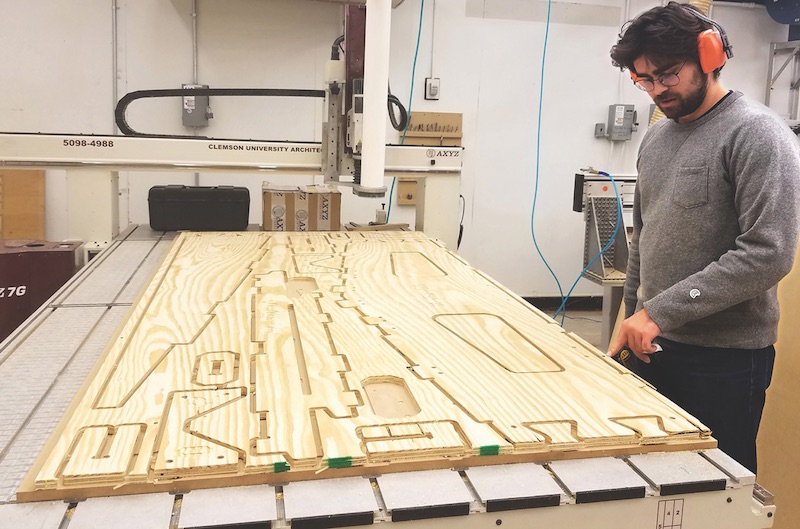

Clemson architecture student Paul Mosher cuts components for a full-scale mockup. Courtesy Clemson University School of Architecture.

Clemson architecture student Paul Mosher cuts components for a full-scale mockup. Courtesy Clemson University School of Architecture.

Related Stories

75 Top Building Products | Apr 22, 2024

Enter today! BD+C's 75 Top Building Products for 2024

BD+C editors are now accepting submissions for the annual 75 Top Building Products awards. The winners will be featured in the November/December 2024 issue of Building Design+Construction.

AEC Tech | Feb 20, 2024

AI for construction: What kind of tool can artificial intelligence become for AEC teams?

Avoiding the hype and gathering good data are half the battle toward making artificial intelligence tools useful for performing design, operational, and jobsite tasks.

Sustainability | Nov 1, 2023

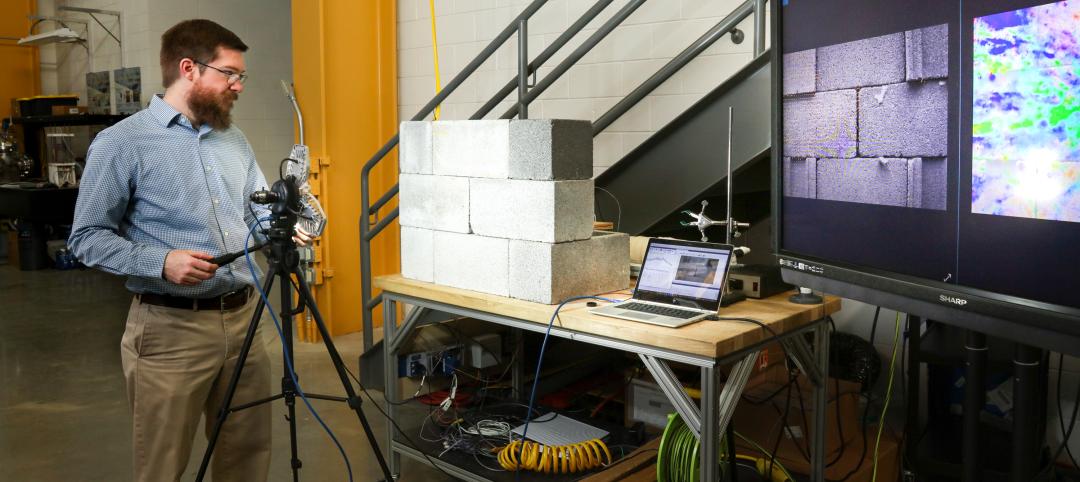

Researchers create building air leakage detection system using a camera in real time

Researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory have developed a system that uses a camera to detect air leakage from buildings in real time.

Resiliency | Aug 7, 2023

Creative ways cities are seeking to beat urban heat gain

As temperatures in many areas hit record highs this summer, cities around the world are turning to creative solutions to cope with the heat. Here are several creative ways cities are seeking to beat urban heat gain.

AEC Innovators | Jun 15, 2023

Rogers-O'Brien Construction pilots wearables to reduce heat-related injuries on jobsites

Rogers-O'Brien Construction (RO) has launched a pilot program utilizing SafeGuard, a safety-as-a-service platform for real-time health and safety risk assessment. Non-invasive wearables connected to SafeGuard continuously monitor personnel to prevent heat exhaustion on jobsites, reducing the risk of related injuries. RO is the first general contractor to pilot this program.

Office Buildings | May 15, 2023

Sixteen-story office tower will use 40% less energy than an average NYC office building

This month marks the completion of a new 16-story office tower that is being promoted as New York City’s most sustainable office structure. That boast is backed by an innovative HVAC system that features geothermal wells, dedicated outdoor air system (DOAS) units, radiant heating and cooling, and a sophisticated control system to ensure that the elements work optimally together.

Design Innovation Report | Apr 27, 2023

BD+C's 2023 Design Innovation Report

Building Design+Construction’s Design Innovation Report presents projects, spaces, and initiatives—and the AEC professionals behind them—that push the boundaries of building design. This year, we feature four novel projects and one building science innovation.

Design Innovation Report | Apr 19, 2023

Reinforced concrete walls and fins stiffen and shade the National Bank of Kuwait skyscraper

When the National Bank of Kuwait first conceived its new headquarters more than a decade ago, it wanted to make a statement about passive design with a soaring tower that could withstand the extreme heat of Kuwait City, the country’s desert capital.

Design Innovation Report | Apr 19, 2023

HDR uses artificial intelligence tools to help design a vital health clinic in India

Architects from HDR worked pro bono with iKure, a technology-centric healthcare provider, to build a healthcare clinic in rural India.

3D Printing | Apr 11, 2023

University of Michigan’s DART Laboratory unveils Shell Wall—a concrete wall that’s lightweight and freeform 3D printed

The University of Michigan’s DART Laboratory has unveiled a new product called Shell Wall—which the organization describes as the first lightweight, freeform 3D printed and structurally reinforced concrete wall. The innovative product leverages DART Laboratory’s research and development on the use of 3D-printing technology to build structures that require less concrete.