The Harvard Center for Green Buildings and Cities (CGBC) has completed the retrofitting of its 4,600-sf headquarters in Cambridge, Mass., built in 1924, into a living laboratory called HouseZero, whose design is driven by ambitious performance targets that include nearly zero energy use for heating and cooling, zero electrical lighting during the day, operating with 100% natural ventilation, and producing zero carbon emissions.

Snohetta was this project’s chief architect, and Skanska Teknikk Norway its lead energy engineer.

A prototype, HouseZero has been set up to address a chronic problem within the built environment: inefficient existing structures. The building inventory in the U.S. is estimated to account for 40% of the country’s energy consumption, with 25% of that usage attributed to housing alone. The annual costs of residential energy consumption are enormous: $230 billion for heating, cooling and powering the nation’s 113.6 million households.

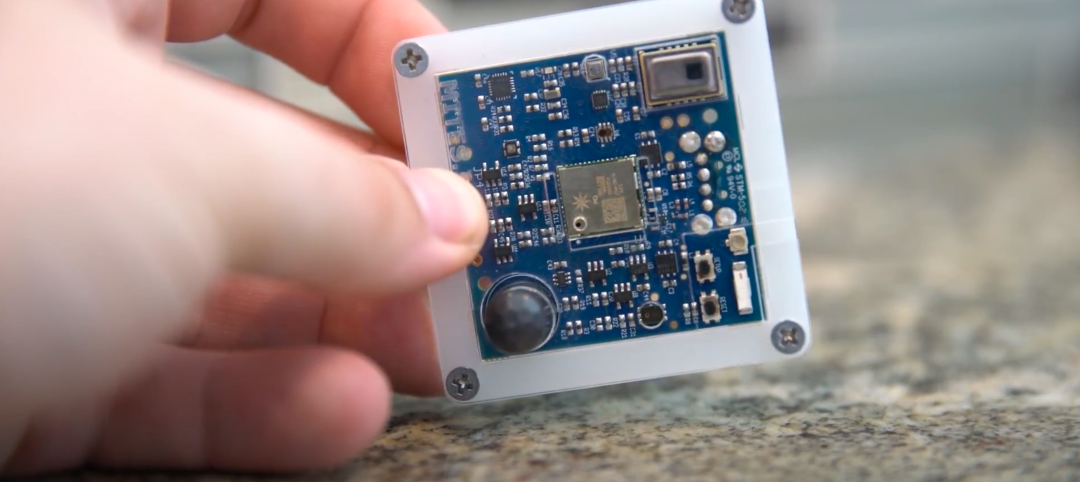

CGBC, at the Harvard Graduate School of Design, has embedded hundreds of sensors connected by several miles of wiring within each component of HouseZero, from which it will draw data points that inform its researchers about the building’s behaviors. These data will be the basis of computational simulations for fuel research that could help the Center develop new systems and algorithms that promote energy efficiency, health, and sustainability.

The goal of HouseZero is to create a blueprint for reducing energy demands and increasing cost savings for property owners. “HouseZero challenged us to rethink the conventions of building design and operation to enhance lifelong efficiency and quality of life for occupants,” says Ali Malkawi, founding director of CGBC, and creator and leader of the HouseZero project.

An example of this rethinking is natural ventilation that is controlled by a window actuation system that employs sophisticated software and sensors arrays to automatically open and close windows to maintain a quality internal environment throughout the year. The building itself will strive for best possible comfort. However, Malkawi notes, a window can always be opened manually to ensure individual comfort.

HouseZero’s third floor features a flexible, highly-controlled and monitored experimental space—dubbed the LiveLab—that’s hardwired to the building’s energy exchange system. The space will allow for the testing, swapping, and optimization of new technologies. An immediate goal is to beta test new technologies that can eventually replace the building’s ground source heat pump for peak conditions.

HouseZero is naturally ventilated, and designed to use only natural lighting during the daytime hours. Image: Michael Grimm

The building will also be used to research how structures connect with and respond to its natural environment. Its envelope and materials were designed to interact with the seasons and the exterior environment. The building, according to CGBC, will adjust itself to reach thermal comfort for its occupants.

HouseZero will achieve zero net energy with the help of a rooftop PV array that provides renewable electrical energy for the heat pump as well as for energy required by user equipment. A battery system is employed for night time use and low-sun conditions.

To meet proposed emission cuts of the Paris agreement, HouseZero will offset the hidden emissions generated throughout the building’s anticipated 60-year life cycle, from the fabrication and transport of building materials and construction processes, to maintenance and decommissioning.

The rest of the renovation team on this project included Columbia Construction (CM), Silman Associates (SE), BR+A (MEP/FP/lighting), Bristol Engineering (CE), WindowMaster (BAS/Controls/Natural Ventilation systems), Brekke & Strand Akustikk (acoustrics), Jensen Hughes (code and accessibility consultant), Haley & Aldrich (geotechnical engineer), Syska Hennessy (vertical transportation), Kalin Associates (specifications), Siemens Building Technologies (security systems), Solect Energy (photovoltaic systems), Reed Hilderbrand (landscape architect), Harvard Planning and Project Management; CSL Consulting (project management), and Harvard Graduate School of Design (operations support).

Related Stories

Mass Timber | May 3, 2023

Gensler-designed mid-rise will be Houston’s first mass timber commercial office building

A Houston project plans to achieve two firsts: the city’s first mass timber commercial office project, and the state of Texas’s first commercial office building targeting net zero energy operational carbon upon completion next year. Framework @ Block 10 is owned and managed by Hicks Ventures, a Houston-based development company.

AEC Tech | May 1, 2023

Utilizing computer vision, AI technology for visual jobsite tasks

Burns & McDonnell breaks down three ways computer vision can effectively assist workers on the job site, from project progress to safety measures.

Design Innovation Report | Apr 27, 2023

BD+C's 2023 Design Innovation Report

Building Design+Construction’s Design Innovation Report presents projects, spaces, and initiatives—and the AEC professionals behind them—that push the boundaries of building design. This year, we feature four novel projects and one building science innovation.

Building Technology | Apr 24, 2023

Let’s chat about AI: How design and construction firms are using ChatGPT

Tech-savvy AEC firms that already use artificial intelligence to enhance their work view the startling evolution of ChatGPT mostly in a positive light as a potential tool for sharing information and training employees and trade partners. However, the efficacy of ChatGPT is likely to rest on the construction industry’s aggregation of quality data that, until recently, has been underwhelming for getting the greatest bang from AI and machine learning.

Design Innovation Report | Apr 19, 2023

HDR uses artificial intelligence tools to help design a vital health clinic in India

Architects from HDR worked pro bono with iKure, a technology-centric healthcare provider, to build a healthcare clinic in rural India.

3D Printing | Apr 11, 2023

University of Michigan’s DART Laboratory unveils Shell Wall—a concrete wall that’s lightweight and freeform 3D printed

The University of Michigan’s DART Laboratory has unveiled a new product called Shell Wall—which the organization describes as the first lightweight, freeform 3D printed and structurally reinforced concrete wall. The innovative product leverages DART Laboratory’s research and development on the use of 3D-printing technology to build structures that require less concrete.

Contractors | Apr 10, 2023

What makes prefabrication work? Factors every construction project should consider

There are many factors requiring careful consideration when determining whether a project is a good fit for prefabrication. JE Dunn’s Brian Burkett breaks down the most important considerations.

Smart Buildings | Apr 7, 2023

Carnegie Mellon University's research on advanced building sensors provokes heated controversy

A research project to test next-generation building sensors at Carnegie Mellon University provoked intense debate over the privacy implications of widespread deployment of the devices in a new 90,000-sf building. The light-switch-size devices, capable of measuring 12 types of data including motion and sound, were mounted in more than 300 locations throughout the building.

Cladding and Facade Systems | Apr 5, 2023

Façade innovation: University of Stuttgart tests a ‘saturated building skin’ for lessening heat islands

HydroSKIN is a façade made with textiles that stores rainwater and uses it later to cool hot building exteriors. The façade innovation consists of an external, multilayered 3D textile that acts as a water collector and evaporator.

Project + Process Innovation | Mar 22, 2023

Onsite prefabrication for healthcare construction: It's more than a process, it's a partnership

Prefabrication can help project teams navigate an uncertain market. GBBN's Mickey LeRoy, AIA, ACHA, LEED AP, explains the difference between onsite and offsite prefabrication methods for healthcare construction projects.