Located in Williamstown, Ky., the Ark Encounter, a 510-foot long wooden boat, is designed to be a family-oriented, historically authentic and environmentally friendly attraction. Created by Answers in Genesis (AiG), a Christian ministry, the Ark Encounter opens in July, 2016, and will bring to life the depictions of the historical events of Noah’s Ark.

The Ark Encounter, a $91.5 million project, is phase one of an entire religious theme park. Additional phases to be completed on the 800-acre site include a pre-flood city, a petting zoo and a walk-through aviary. The Creation Museum, an AiG museum located 40 miles from the Ark, was the first job Applied Mechanical Systems, the mechanical contractor for the Ark, did for AiG.

“They liked our work,” said Brian Hogue, plumbing foreman for Applied Mechanical Systems (AMS). “Our mechanical engineers went to Troyer Group, who is constructing the Ark Encounter, about four years ago and helped their engineering firm with code issues and three years later, when they were ready to start construction, they gave us the job.”

Troyer Group specified the use of Viega ProPress for copper for all the potable water lines, in sizes ranging from ½" to 4", and Viega MegaPressG for the natural gas lines, ranging from ½" to 2".

Ronald Troyer, Senior Vice President of Troyer Group, has included Viega products in various projects. He and Hogue emphasized that the flameless technology and ease of use were the motivating factors for specifying Viega.

Flameless install at largest timber-frame structure

Flameless install at largest timber-frame structure

“The no-heat and no-flame installation of plumbing piping was a definite plus,” said Troyer. “As with most projects of this scale, meeting a tight construction schedule was also a great fit for Viega products. The ease of installation which equated to cost savings with copper pipe was also a plus.”

Hogue agreed and expressed his appreciation for the overall quality of the Viega products and the difference it made on this project.

“Seeing how this is the largest timber frame wood structure in the world, they did not want open flame in the Ark,” Hogue said. “In my opinion, Viega MegaPress and Viega ProPress fittings are built well. There are a lot fewer leaks than other press manufacturers’ fittings. Plus, you save more time, making them cost effective.”

AMS has been installing Viega system solutions in applications where soldering would be prohibitive, and the time saved gives them the opportunity to stay ahead of the game on many jobs.

“It’s great for shut downs in factories where you don’t have time to worry about draining the system,” Hogue said. “In our Dayton offices, we use it a lot in hospitals, since it is a clean process of joining pipe. I highly recommend Viega systems.”

For more information, visit www.viega.us.

Related Stories

Mass Timber | Jan 27, 2023

How to set up your next mass timber construction project for success

XL Construction co-founder Dave Beck shares important preconstruction steps for designing and building mass timber buildings.

Mass Timber | Dec 1, 2022

Cross laminated timber market forecast to more than triple by end of decade

Cross laminated timber (CLT) is gaining acceptance as an eco-friendly building material, a trend that will propel its growth through the end of the 2020s. The CLT market is projected to more than triple from $1.11 billion in 2021 to $3.72 billion by 2030, according to a report from Polaris Market Research.

75 Top Building Products | Nov 30, 2022

75 top building products for 2022

Each year, the Building Design+Construction editorial team evaluates the vast universe of new and updated products, materials, and systems for the U.S. building design and construction market. The best-of-the-best products make up our annual 75 Top Products report.

Wood | Nov 16, 2022

5 steps to using mass timber in multifamily housing

A design-assist approach can provide the most effective delivery method for multifamily housing projects using mass timber as the primary building element.

University Buildings | Nov 13, 2022

University of Washington opens mass timber business school building

Founders Hall at the University of Washington Foster School of Business, the first mass timber building at Seattle campus of Univ. of Washington, was recently completed. The 84,800-sf building creates a new hub for community, entrepreneurship, and innovation, according the project’s design architect LMN Architects.

Building Materials | Nov 2, 2022

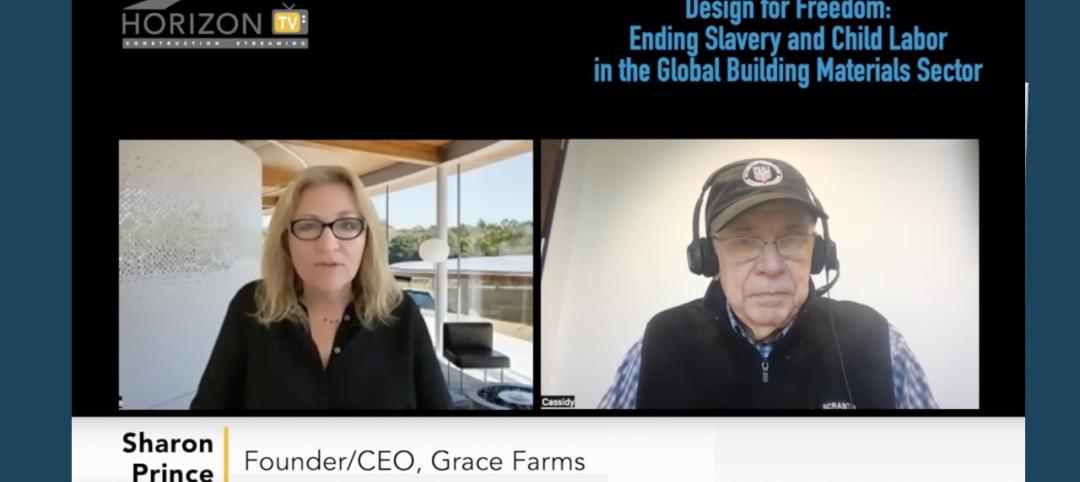

Design for Freedom: Ending slavery and child labor in the global building materials sector

Sharon Prince, Founder and CEO of Grace Farms and Design for Freedom, discusses DFF's report on slavery and enforced child labor in building products and materials.

Wood | Nov 1, 2022

A European manufacturer says its engineered wood products can store carbon for decades

Metsä Wood, a Finland-based manufacturer of engineered wood products, says its sustainable, material-efficient products can store carbon for decades, helping to combat climate change.

| Sep 23, 2022

High projected demand for new housing prompts debate on best climate-friendly materials

The number of people living in cities could increase to 80% of the total population by 2100. That could require more new construction between now and 2050 than all the construction done since the start of the industrial revolution.

Mass Timber | Aug 30, 2022

Mass timber construction in 2022: From fringe to mainstream

Two Timberlab executives discuss the market for mass timber construction and their company's marketing and manufacturing strategies. Sam Dicke, Business Development Manager, and Erica Spiritos, Director of Preconstruction, Timberlab, speak with BD+C's John Caulfield.

Building Materials | Aug 3, 2022

Shawmut CEO Les Hiscoe on coping with a shaky supply chain in construction

BD+C's John Caulfield interviews Les Hiscoe, CEO of Shawmut Design and Construction, about how his firm keeps projects on schedule and budget in the face of shortages, delays, and price volatility.