When most people think of radiant heat or hydronic snowmelt, the usual applications are warm floors, heated sidewalks and snow-free driveways. Viega Radiant Design Services in Nashua, NH, has designed and quoted thousands of projects like those, but occasionally they receive requests for assistance with out-of-the-box projects.

The Big Bear Area Regional Wastewater Agency (BBARWA) in Big Bear, CA, contacted Viega Radiant Design Services with a project that needed an innovative solution. A byproduct of the water treatment process is sludge, composed of 25% solids and 75% water. Since the sludge must be hauled by truck to an off-site disposal area, BBARWA needed a way to reduce the water content and weight of the sludge, making it less expensive to haul. BBARWA tried several different methods to dry the sludge with only marginal success, so they decided to devise a new system that would be more effective, more efficient and would reduce the odor complaints.

Viega Radiant Design Services worked on the specifics of the slab heating system design, focusing on what would be required to generate enough heat from the slab to meet the sludge-drying objectives. Viega design engineers used finite element analysis (FEA) to determine the optimum tubing size, spacing and install-depth in the slab based on the water temperature supplied from the diesel generator’s exhaust. Due to the shape and size of the 315- by 60-foot heated slab, it was clear that this project was an excellent application for Viega’s revolutionary Viega Climate Mat® system.

Since the facility produces its own electricity using three natural gas generators, the water flowing through the slab would be heated with a heat exchanger in one of the generator’s exhaust, making it an efficient co-generation system. Within the first year alone, the new system saved approximately $200,000 in transportation and fuel costs.

Viega Climate Mat® system

The contractors were impressed with the speed and ease of installation of the Viega Climate Mat and appreciated the support provided by Viega throughout the entire process, from design to installation.

“Anything you said you could do, you did it,” said Plant Manager Fred Uhler. “They were topnotch guys from the sales staff, to the design support. They were excited about the project. It’s great to work with people like that.”

Once the covered drying bed building was completed, the system went into operation in June 2014. Within a few months, it became clear that this unique application of radiant heating was a resounding success. In 2015, Uhler reported that the system was performing beyond expectations and even better in the low-humidity winter months.

“This system is self-operational, and I’ve had zero maintenance issues with it from Viega’s side of things,” Uhler said. “It couldn’t be any better.”

Additionally, the project received the California Water Association Desert Mountain Award for Innovation.

While conventional radiant heating and snow melting projects are everyday business for the Viega team, projects like the Big Bear Area Regional Wastewater Agency covered drying bed are prime examples of how Viega can design and deliver innovative solutions that improve lives, reduce energy usage and help protect the environment.

For more information on Viega system solutions, visit Viega.us.

Viega

800.976.9819

insidesales@viega.us

www.viega.us

Related Stories

Industrial Facilities | Sep 3, 2015

DATA CENTER SECTOR GIANTS: Fluor, Gensler, Holder Construction among top data center AEC firms

BD+C's rankings of the nation's largest data center sector design and construction firms, as reported in the 2015 Giants 300 Report

Industrial Facilities | Aug 18, 2015

BIG crowdfunds steam ring prototype for Amager Bakke power plant project

The unusual power plant/ski slope project in Copenhagen will feature a smokestack that will release a ring-shaped puff for every ton of CO2 emitted.

Industrial Facilities | Aug 3, 2015

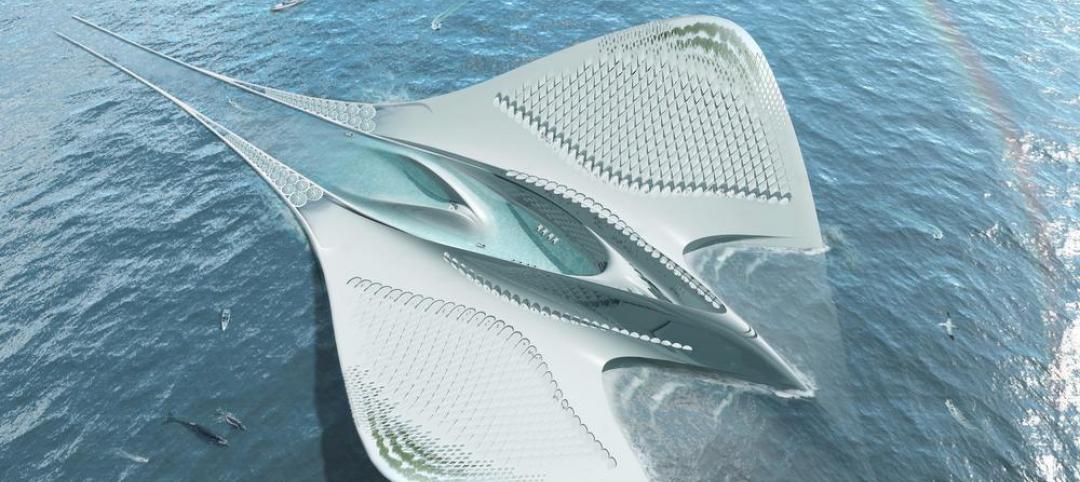

Architect Jacques Rougerie envisions floating city to function as roving laboratory

The manta ray-shaped vessel will be completely self-sustaining, run on marine energy, and produce no waste.

Contractors | Jul 29, 2015

Consensus Construction Forecast: Double-digit growth expected for commercial sector in 2015, 2016

Despite the adverse weather conditions that curtailed design and construction activity in the first quarter of the year, the overall construction market has performed extremely well to date, according to AIA's latest Consensus Construction Forecast.

University Buildings | Jul 21, 2015

Maker spaces: Designing places to test, break, and rebuild

Gensler's Kenneth Fisher and Keller Roughton highlight recent maker space projects at MIT and the University of Nebraska that provide just the right mix of equipment, tools, spaces, and disciplines to spark innovation.

Architects | Jul 20, 2015

New York design competition looks to shed the sidewalk shed

New York, which has nearly 200 total miles of sidewalk sheds, is seeking a concept that is practical but that also looks good.

Industrial Facilities | Jul 14, 2015

Tesla may seek to double size of Gigafactory in Nevada

Tesla Motors purchased an additional 1,200 acres next to the Gigafactory and is looking to buy an additional 350 acres.

Industrial Facilities | Jul 10, 2015

Multi-million dollar vertical farm project breaks ground in Newark, N.J.

The vertical farm by commercial grower AeroFarms will be the world’s largest indoor vertical farm.

Green | Jul 7, 2015

Philips sheds new light on growing fresh food indoors

A research center in The Netherlands is testing the latest techniques in urban farming.

Industrial Facilities | Jun 26, 2015

Google to convert an Alabama coal-burning plant to a data center running on clean energy

The $600 million conversion project will be Google's 14th data center globally, but the first it has committed to in eight years.