|

|

The use of BIM software helped the Building Team overcome tight site conditions along Chicago’s lakefront during the renovation project. |

To complete the $55 million renovation of the historic John G. Shedd Aquarium in the allotted 17-month schedule, the Building Team had to move fast to renovate and update exhibit and back-of-house maintenance spaces, expand the visitor group holding area, upgrade the mechanical systems, and construct a single-story steel structure on top of the existing oceanarium to accommodate staff office space—all while the facility remained fully operational.

To help coordinate the complex construction schedule and deal with tight working conditions along Chicago's lakefront, the team—led by Walsh Construction and Valerio DeWalt Train—modeled a significant portion of the reconstruction work, including the 24,000-sf office addition, using building information modeling software. Crane location, material staging, steel hoisting and erection schedules, and patron/staff egress pathways were all carefully coordinated using BIM.

Other aspects of the project could not be so carefully anticipated due to unforeseen conditions in the 79-year-old structure. When the aquarium's three-million-gallon tank was drained to make way for a new pool lining, the team discovered that hydrostatic pressure was the only thing holding the acrylic viewing windows in place. To avoid the costly and time-consuming process of hoisting the massive windows out of the pool during the renovation, the team devised a clever structural bracing solution that used brackets installed underwater to hold the windows in place.

The team also had to devise three custom rolling scaffold platforms to permit installation of a new theatrical tension grid and A/V lighting systems to the oceanarium's structural trusses, which span as high as 80 feet over the pools. The special scaffold platforms were designed to cling to and roll along the bottom flanges of the trusses, and to flare out as they moved toward the curtain wall, providing workers safe access to the trusses.

“This was a technically challenging project, with a passionate client and lots of demands,” said Reconstruction Awards judge Matthew H. Johnson, PE, associate principal with Simpson Gumpertz & Heger, Waltham, Mass. —Dave Barista, Managing Editor

Related Stories

Mass Timber | May 3, 2023

Gensler-designed mid-rise will be Houston’s first mass timber commercial office building

A Houston project plans to achieve two firsts: the city’s first mass timber commercial office project, and the state of Texas’s first commercial office building targeting net zero energy operational carbon upon completion next year. Framework @ Block 10 is owned and managed by Hicks Ventures, a Houston-based development company.

AEC Tech | May 1, 2023

Utilizing computer vision, AI technology for visual jobsite tasks

Burns & McDonnell breaks down three ways computer vision can effectively assist workers on the job site, from project progress to safety measures.

Design Innovation Report | Apr 27, 2023

BD+C's 2023 Design Innovation Report

Building Design+Construction’s Design Innovation Report presents projects, spaces, and initiatives—and the AEC professionals behind them—that push the boundaries of building design. This year, we feature four novel projects and one building science innovation.

Building Technology | Apr 24, 2023

Let’s chat about AI: How design and construction firms are using ChatGPT

Tech-savvy AEC firms that already use artificial intelligence to enhance their work view the startling evolution of ChatGPT mostly in a positive light as a potential tool for sharing information and training employees and trade partners. However, the efficacy of ChatGPT is likely to rest on the construction industry’s aggregation of quality data that, until recently, has been underwhelming for getting the greatest bang from AI and machine learning.

Design Innovation Report | Apr 19, 2023

HDR uses artificial intelligence tools to help design a vital health clinic in India

Architects from HDR worked pro bono with iKure, a technology-centric healthcare provider, to build a healthcare clinic in rural India.

3D Printing | Apr 11, 2023

University of Michigan’s DART Laboratory unveils Shell Wall—a concrete wall that’s lightweight and freeform 3D printed

The University of Michigan’s DART Laboratory has unveiled a new product called Shell Wall—which the organization describes as the first lightweight, freeform 3D printed and structurally reinforced concrete wall. The innovative product leverages DART Laboratory’s research and development on the use of 3D-printing technology to build structures that require less concrete.

Contractors | Apr 10, 2023

What makes prefabrication work? Factors every construction project should consider

There are many factors requiring careful consideration when determining whether a project is a good fit for prefabrication. JE Dunn’s Brian Burkett breaks down the most important considerations.

Smart Buildings | Apr 7, 2023

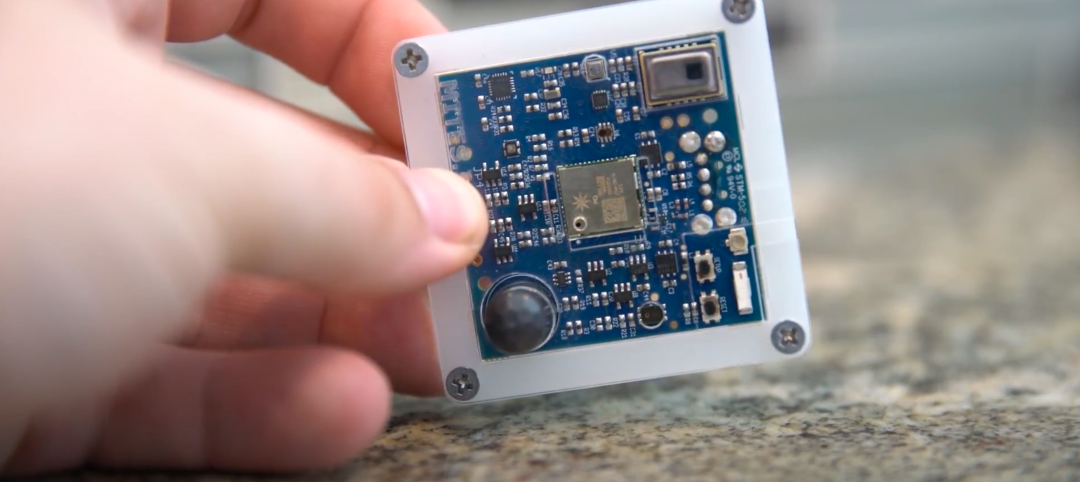

Carnegie Mellon University's research on advanced building sensors provokes heated controversy

A research project to test next-generation building sensors at Carnegie Mellon University provoked intense debate over the privacy implications of widespread deployment of the devices in a new 90,000-sf building. The light-switch-size devices, capable of measuring 12 types of data including motion and sound, were mounted in more than 300 locations throughout the building.

Cladding and Facade Systems | Apr 5, 2023

Façade innovation: University of Stuttgart tests a ‘saturated building skin’ for lessening heat islands

HydroSKIN is a façade made with textiles that stores rainwater and uses it later to cool hot building exteriors. The façade innovation consists of an external, multilayered 3D textile that acts as a water collector and evaporator.

Project + Process Innovation | Mar 22, 2023

Onsite prefabrication for healthcare construction: It's more than a process, it's a partnership

Prefabrication can help project teams navigate an uncertain market. GBBN's Mickey LeRoy, AIA, ACHA, LEED AP, explains the difference between onsite and offsite prefabrication methods for healthcare construction projects.