Having little experience with the ARRIS.tile product, the architect for this project was educated on the Arriscraft line by Brickstone Inc. (which represents the stone company in Colorado, Utah, Wyoming and Idaho). Jason Evans, Construction & Marketing Manager at Scott P. Evans, says, ”After spending some time with the local product rep, we saw the value in incorporating ARRIS.tile into our job. The color options were great, working with a thin material was advantageous for our specific job, and the quality, durability and warranty sold us on the product. On the appropriate project we would definitely use ARRIS.tile again. We’ve already recommended it to other architects searching for this type of product.”

ProGUARDTM- An exciting, continuous insulation solution for thin adhered masonry industry

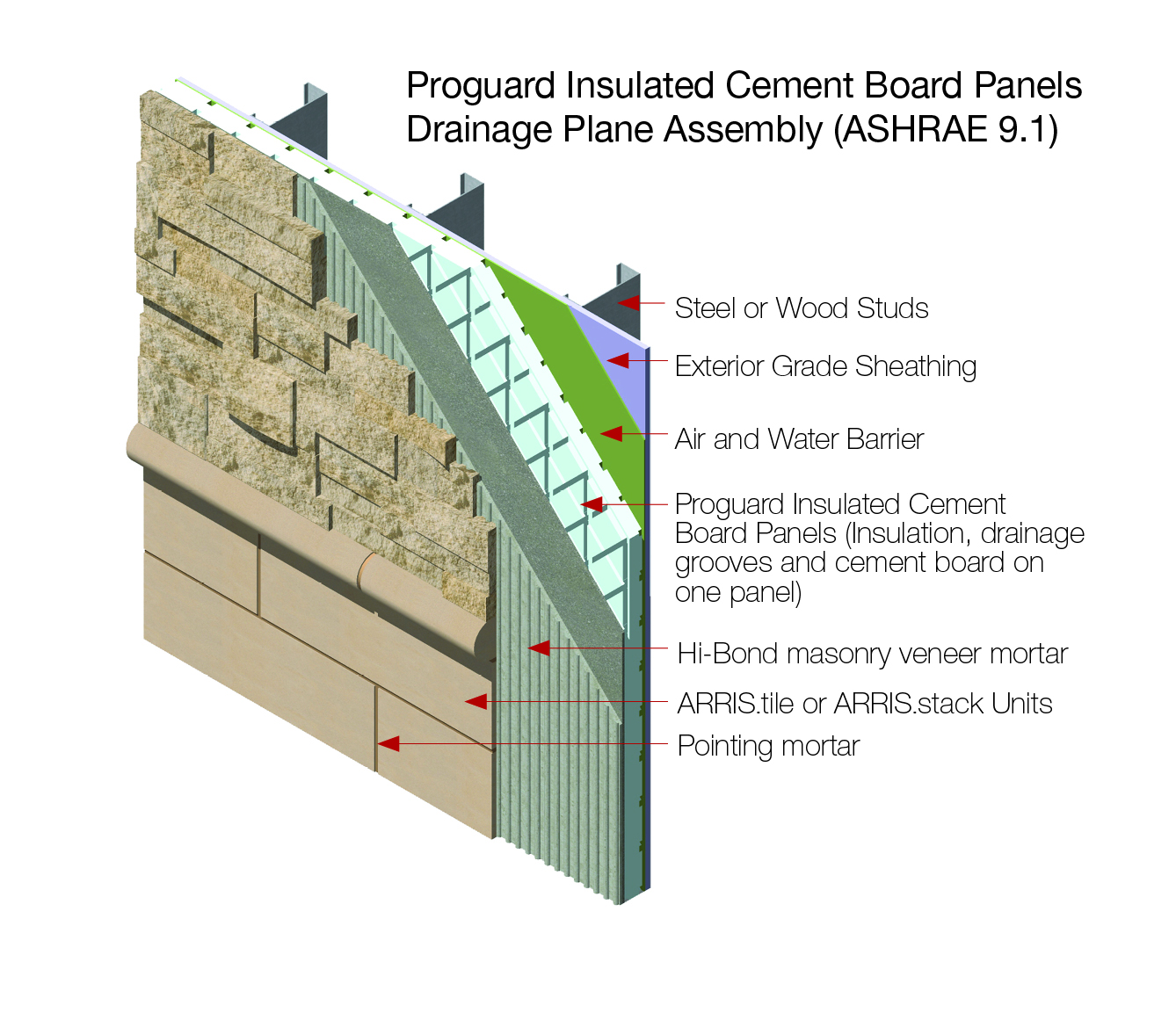

While naturally-made ARRIS.tile was used for the stunning cladding material, the wall system itself was revolutionary for the thin-adhered veneer market. In addition to using the Laticrete Masonry Veneer Installation System (MVIS) to adhere the units and waterproof the assembly, the designers also chose to use the ProGUARDTM insulated cement board panels as well. These panels are constructed by laminating ¼” thick cement board panels to EPS insulation. The EPS insulation can be provided as thin as 1-1/2” up to 6” in thickness with increments of increasing thickness of 1/8” (i.e. 1-1/2”, 1-5/8”, 1-3/4” etc…). Pre-selected and pre-specified screws for the different thicknesses of panels and the different possible substrates complete the ease of specifying and using the panels.

ProGUARDTM allows designers to meet the continuous insulation requirements of the more stringent energy codes introduced over the past few years, such as ASHRAE 90.1 and IECC, which require lower U-values (higher effective R-values) for wall construction.

ProGUARDTM panels also have drainage grooves cut into the front and back of the insulation to achieve drainage planes. These drainage planes allow for wind driven moisture behind the veneer to weep from the system and also allow moisture as the result of condensation (e.g. from vapor flow, air flow, dew points, etc.) to escape the wall system, effectively creating a thin-adhered masonry veneer rainscreen.

ProGUARDTM eliminates the need to install a drainage mat, insulation, and cement board in three separate steps. As a single product, ProGUARDTM collapses all these materials and their benefits into one – providing continuous insulation, drainage planes, and a stable and fully cured substrate to adhere thin-masonry veneers.

Arriscraft continues to lead the industry with high performance, naturally-made stone products and best practices in installation systems.

Project Details:

Project: Carbon County Courthouse & Administration Building

Location: Price, Utah

Architect: Scott P. Evans – Architect & Associates P.C. Contractor: Ascent Construction

Product: ARRIS.tile Café Smooth & Rocked Installed over ProGUARD Insulated Cement Board Panels with Laticrete MVIS materials.

Related Stories

| Jul 8, 2014

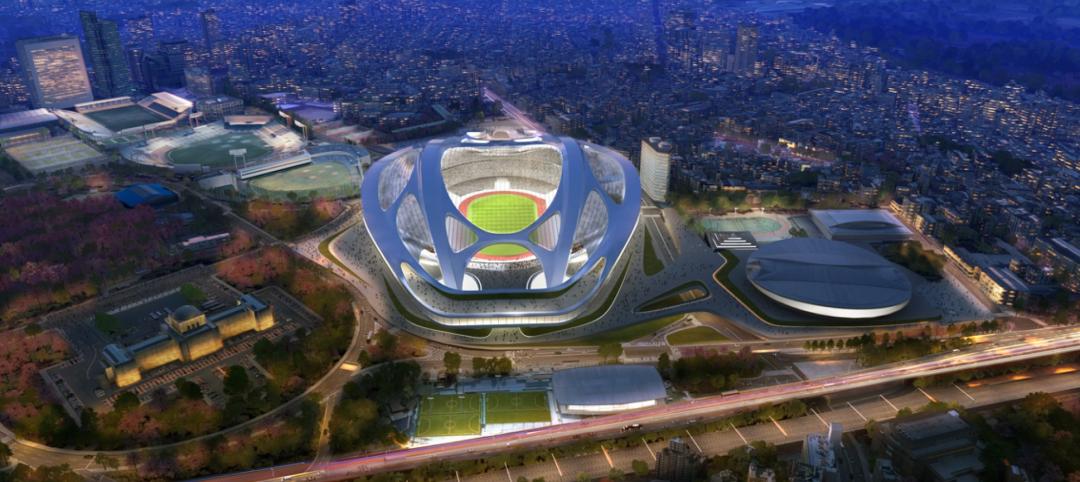

Does Zaha Hadid’s Tokyo Olympic Stadium have a design flaw?

After being criticized for the cost and size of her stadium design for the 2020 Olympics in Tokyo, a Japanese architect points out a major design flaw in the stadium that may endanger the spectators.

| Mar 20, 2014

Common EIFS failures, and how to prevent them

Poor workmanship, impact damage, building movement, and incompatible or unsound substrate are among the major culprits of EIFS problems.

| Mar 4, 2014

How EIFS came to America

Design experts from Hoffmann Architects offer a brief history of exterior insulation and finish systems in the U.S.

| Dec 31, 2013

Top 10 blog posts from 2013

BD+C editors and our contributors posted hundreds of blogs in 2013. Here's a recap of the most popular topics. They include valuable lessons from one of the first BIM-related lawsuits and sage advice from AEC legend Arthur Gensler.

| Sep 26, 2013

Sheep's wool insulation, bio-brick among Cradle to Cradle product innovation finalists

Ten finalists are competing for $250,000 in prizes from the Cradle to Cradle Products Innovation Institute and Make It Right.

| Aug 23, 2013

Demand for commissioning services on the rise: PECI/BCA survey

Demand for the services of commissioning professionals is rising and will continue to rise into the near future, according to a survey by PECI and the Building Commissioning Association (BCA).

| Apr 16, 2013

5 projects that profited from insulated metal panels

From an orchid-shaped visitor center to California’s largest public works project, each of these projects benefited from IMP technology.