Over the years, our industry has relied heavily on reducing the center of glass (COG) U-factor as a way of driving down overall fenestration U-factors (thermal transmittance). Strategies have included increasing the performance of low-emissivity (low-e) coatings, using multiple coatings, addition of inert gases, and more recently, moving to triple-pane units. However, the COG U-factor makes up only part of a window’s performance. To achieve the lowest fenestration thermal transmittance and highest condensation resistance, it is necessary to look more broadly at the window as a system, including the edges: The frame and edge of glass (EOG).

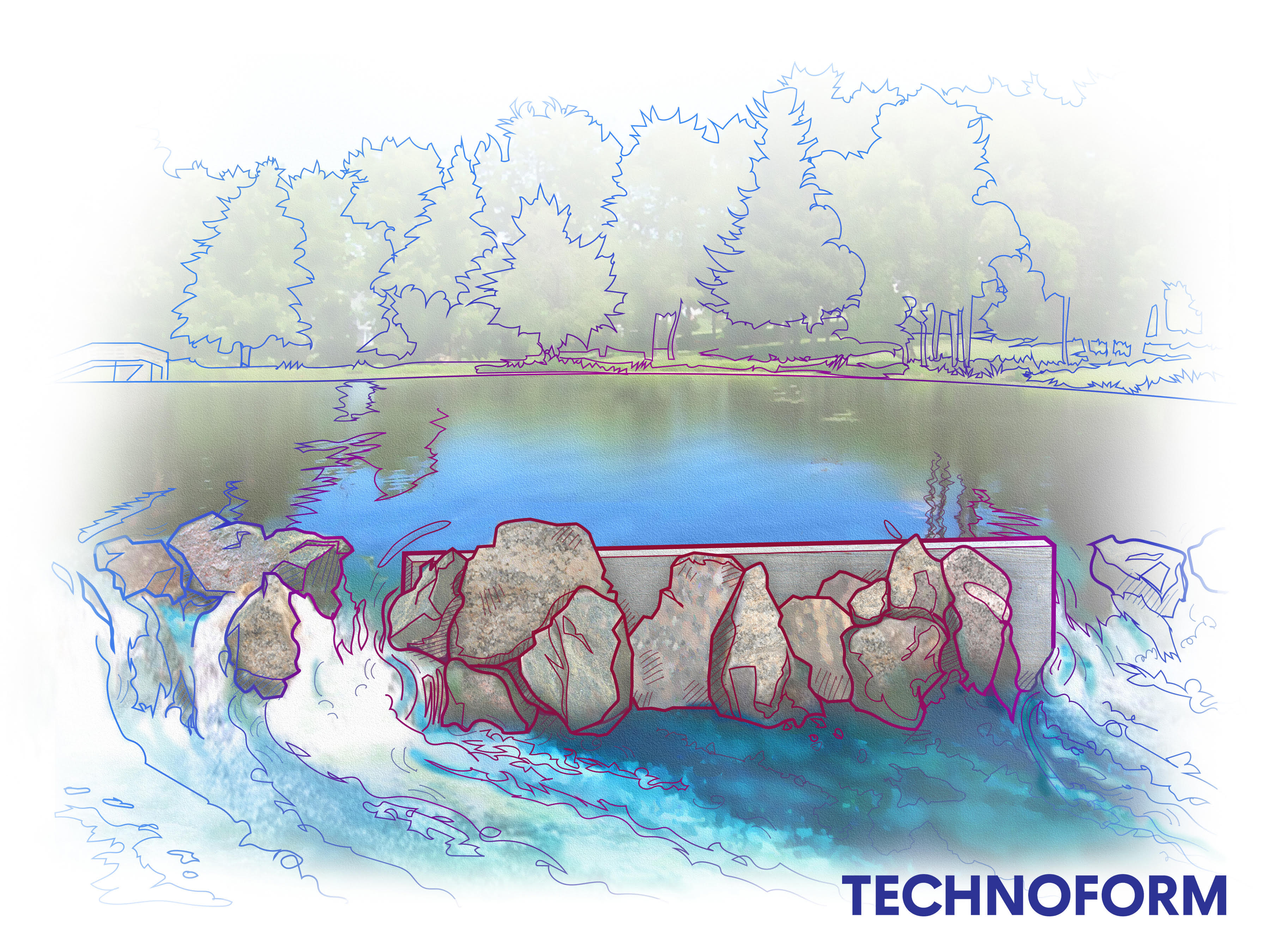

Think of a window as the thermal equivalent of damming a river at its center, yet forgetting to block water flow all the way to its banks.

Think of a window as the thermal equivalent of damming a river at its center, yet forgetting to block water flow all the way to its banks.

Focusing on preventing heat flow through the COG only is the thermal equivalent of damming a river at its center, but not spanning the entire river. In the case of the river, the water just flows around the edges. Likewise, in the case of the window, the energy still flows through it even if the COG conductance is low. It does so by taking the path of least resistance around the edges of the window – through the frame and EOG.

Whole fenestration U-factor as a function of center of glass (COG), edge of (EOG) and frame thermal performance.

Whole fenestration U-factor as a function of center of glass (COG), edge of (EOG) and frame thermal performance.

The graph illustrates how the window U-factor varies with the COG, frame and EOG (spacer) performance, and demonstrates how the specifications of the edges of a window control the overall U-factor performance. The data confirms that when specifying a fenestration system, the first focus should be on improving the performance of the frame (biggest influence) and EOG before specifying the COG package. Spec the edge.

Having a high-performance edge is an enabler for achieving a high-performance window system, and it can provide greater flexibility in glass choice because the highest COG U-factor may not be needed. A top-performing frame can achieve the same performance with a dual-pane glazing as a poorer-performing frame with triple-pane glazing.

Because condensation resistance is also driven by thermal bridging (or lack thereof) at the fenestration edge, improving frame and EOG thermal performance first has a dual benefit of increasing performance on this dimension too. For the example above, the condensation resistance of the non-thermally broken window wall is only 40 compared to 53 for the thermally broken system.

The moral of the story is that when designing windows for thermal and condensation-resistance performance, start with the edge first. Doing so delivers higher performance and more flexibility, reduced complexity and potentially reduced cost for the glazing in-fill. In other words, before getting caught up in the middle, spec the edge. To learn more, visit https://spectheedge.com/

Related Stories

| Apr 14, 2011

How AEC Professionals Choose Windows and Doors

Window and door systems need to perform. Respondents to our annual window and door survey overwhelmingly reported that performance, weather resistance, durability, and quality were key reasons a particular window or door was specified.

| Apr 11, 2011

From Wired Glass to Clear Solutions: Designing with Fire Rated Glass Today

This white paper provides readers with a solid understanding of fire rated glass based on the two types of FRG recognized in the IBC – fire protective and fire resistive glazing. The white paper is intended to give readers the ability to specify the correct, code-approved FRG product for particular applications based on the most up-to-date version of the IBC.

| Mar 22, 2011

Marvin honored by Minnesota Pollution Control Agency

Marvin Windows and Doors has been awarded a Certificate of Commendation by the Minnesota Pollution Control Agency (MPCA). The award honors Marvin for outstanding operation, maintenance and management of its wastewater treatment operations.

| Feb 22, 2011

BHMA proposes new standard for auxiliary locks

The Builders Hardware Manufacturers Association (BHMA) announces the publication of ANSI/BHMA A156.36 - 2010 American National Standard for Auxiliary Locks.

| Feb 10, 2011

7 Things to Know About Impact Glazing and Fire-rated Glass

Back-to-basics answers to seven common questions about impact glazing and fire-rated glass.

| Jan 21, 2011

Music festival’s new home showcases scenic setting

Epstein Joslin Architects, Cambridge, Mass., designed the Shalin Liu Performance Center in Rockport, Mass., to showcase the Rockport Chamber Music Festival, as well at the site’s ocean views.

| Nov 16, 2010

NFRC approves technical procedures for attachment product ratings

The NFRC Board of Directors has approved technical procedures for the development of U-factor, solar heat gain coefficient (SHGC), and visible transmittance (VT) ratings for co-planar interior and exterior attachment products. The new procedures, approved by unanimous voice vote last week at NFRC’s Fall Membership Meeting in San Francisco, will add co-planar attachments such as blinds and shades to the group’s existing portfolio of windows, doors, skylights, curtain walls, and window film.

| Nov 3, 2010

First of three green labs opens at Iowa State University

Designed by ZGF Architects, in association with OPN Architects, the Biorenewable Research Laboratory on the Ames campus of Iowa State University is the first of three projects completed as part of the school’s Biorenewables Complex. The 71,800-sf LEED Gold project is one of three wings that will make up the 210,000-sf complex.

| Nov 3, 2010

Public works complex gets eco-friendly addition

The renovation and expansion of the public works operations facility in Wilmette, Ill., including a 5,000-sf addition that houses administrative and engineering offices, locker rooms, and a lunch room/meeting room, is seeking LEED Gold certification.