A recent survey of AEC firms and real estate owners and developers found a strong majority that had deployed off-site construction in the previous 12 months and planned to utilize it to a greater extent going forward.

The Off-Site Construction Council of the National Institute of Building Sciences in Washington, D.C. conducted its 2018 Off-Site Construction Industry Survey as a follow-up to a 2014 survey to gauge the industry’s interest in off-site construction, which it defines as the planning, design, fabrication, and assembly of building elements at a location other than their final point of assembly onsite.

Ryan Smith of Washington State University and Kambaja Tarr of the University of Utah conducted and compiled the latest survey for NIBS.

“With the ongoing shortage of skilled craft workers (which exceeded two million in 2017), prefabrication in a controlled, off-site environment may become a necessity for many U.S. contractors attempting to remain competitive with a lower-skilled workforce,” the survey states. But as with any new process or technology innovation, and despite growing demand, ”uncertainties accompany the utilization of off-site construction.”

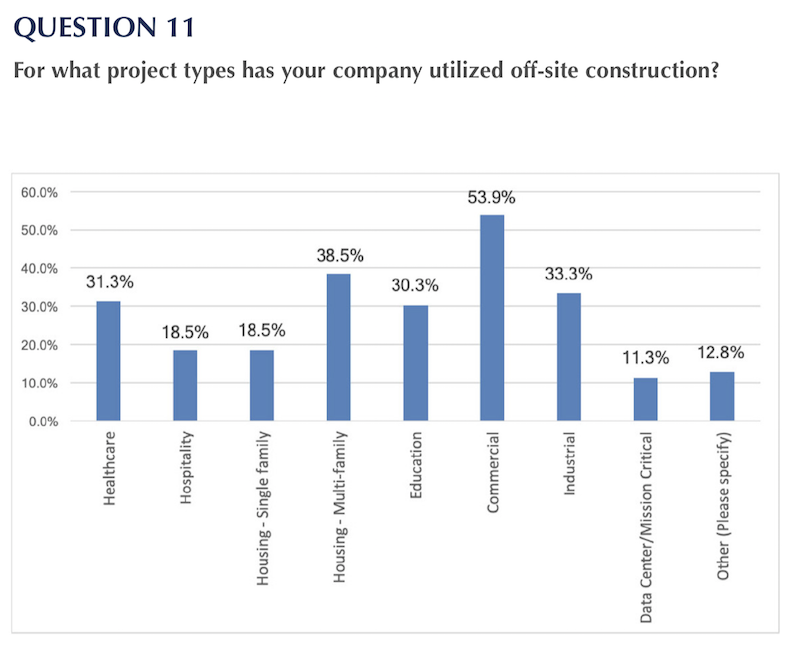

The commercial, multifamily and healthcare sectors are where off-site construction has been finding its greatest demand. Image: NIBS

A total of 205 participants responded to the 2018 Off-Site Construction Industry survey, versus 312 respondents to the 2014 poll. The participating companies provide a variety of different services, including construction management/general contracting (24.75% in 2018; 46.7% in 2014), engineering (21.72% and 38.3%), trade contracting (2.53% and 27.3%), architecture (87.88% and 15%), and owners/developers (10.1% and 8.3%).

Nearly nine of 10 respondents to the 2018 survey (87.72%) had used off-site fabricated components to some degree over the previous 12 months, and more than eight in 10 (81.63%) expected to engage off-site construction more often or the same amount in the following 12 months. (Both percentages were down slightly from the 2014 survey.)

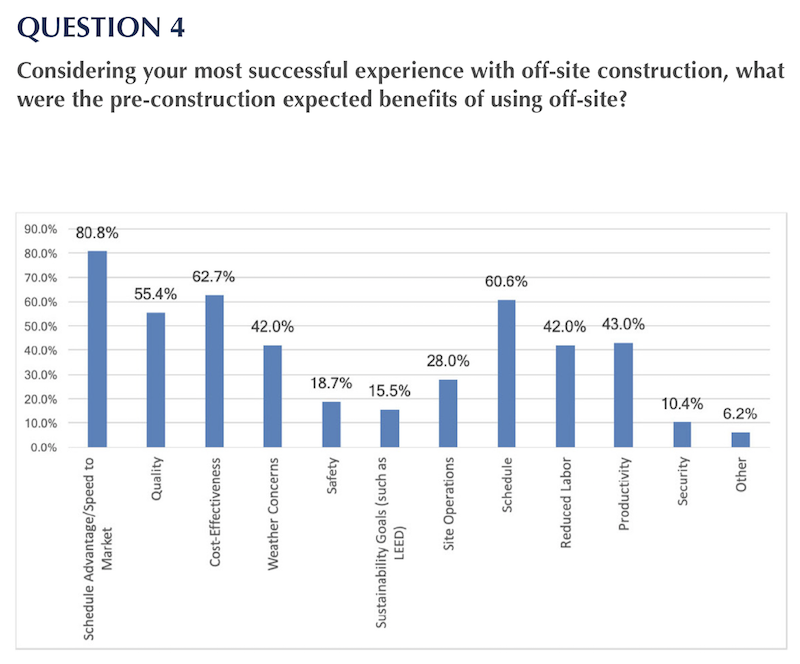

The primary benefit identified in both surveys is a reduced overall project schedule, specifically the duration of the construction phase.

For more than three fifths of respondents (63.22%) designers, architects and engineers were the primary decision makers about when off-site construction is implemented, followed by construction managers or general contractors (47.67%), clients (41.97%), and others, primarily subcontractors (21.24%).

Keeping projects on schedule is where companies that deploy off-site construction have been seeing the greatest benefit. Image: NIBS

Interestingly, however, respondents stated that the most significant barrier to off-site construction is the culture of design and construction in general. Comments indicated that late design changes, lack of collaboration and an adversarial climate for project delivery leads to difficulties in realizing the benefits of off-site construction.

The survey notes that the building component fabrication industry is still maturing and needs more time to integrate effectively with site-built work. In addition, contractors are still learning how to manage off-site products for assembly on-site.

Transportation is another significant barrier: specifically, how far away a factory is located from the construction site.

Respondents in both surveys qualitatively noted that some projects, particularly those with long spans, may not be suited for the use of pre-fabricated elements, and that each project has unique requirements that must be met through an appropriate technical solution.

Related Stories

Higher Education | Oct 24, 2022

Wellesley College science complex modernizes facility while preserving architectural heritage

A recently completed expansion and renovation of Wellesley College’s science complex yielded a modernized structure for 21st century STEM education while preserving important historical features.

Mixed-Use | Oct 20, 2022

ROI on resilient multifamily construction can be as high as 72%

A new study that measured the economic value of using FORTIFIED Multifamily, a voluntary beyond-code construction and re-roofing method developed by the Insurance Institute for Business & Home Safety (IBHS), found the return can be as high as 72%.

40 Under 40 | Oct 19, 2022

Meet the 40 Under 40 class of 2022

Each year, the editors of Building Design+Construction honor 40 architects engineers, contractors, and real estate developers as BD+C 40 Under 40 awards winners. These AEC professionals are recognized for their career achievements, passion for the AEC profession, involvement with AEC industry organizations, and service to their communities.

Designers | Oct 19, 2022

Architecture Billings Index moderates but remains healthy

For the twentieth consecutive month architecture firms reported increasing demand for design services in September, according to a new report today from The American Institute of Architects (AIA).

Building Team | Oct 18, 2022

Brasfield & Gorrie chairman’s home vandalized by anti-development activists

Activists vandalized the home and vehicles of Miller Gorrie, chairman of Birmingham-based Brasfield & Gorrie, in protest of a planned $90 million, 85-acre police, fire and public safety training center in Atlanta.

Mixed-Use | Oct 18, 2022

Mixed-use San Diego tower inspired by coastal experience and luxury travel

The new 525 Olive mixed use San Diego tower was inspired by the coastal experience and luxury travel.

University Buildings | Oct 18, 2022

A carbon-neutral-ready university campus opens in Hong Kong

In early September, the Hong Kong University of Science and Technology (HKUST) officially opened its new, KPF-designed campus in Nansha, Guangzhou (GZ).

Codes and Standards | Oct 17, 2022

Ambitious state EV adoption goals put pressure on multifamily owners to provide chargers

California’s recently announced ban on the sale of new gas-powered vehicles starting in 2035—and New York’s recent decision to follow suit—are putting pressure on multifamily property owners to install charging stations for tenants.

Justice Facilities | Oct 17, 2022

San Antonio’s new courthouse aims to provide safety and security while also welcoming the public

The San Antonio Federal Courthouse, which opened earlier this year, replaces a courthouse that had been constructed as a pavilion for the 1968 World’s Fair.

Market Data | Oct 14, 2022

ABC’s Construction Backlog Indicator Jumps in September; Contractor Confidence Remains Steady

Associated Builders and Contractors reports today that its Construction Backlog Indicator increased to 9.0 months in September, according to an ABC member survey conducted Sept. 20 to Oct. 5.