Sacramento International Airport’s Central Terminal and Concourse B is the largest public construction capital improvement project undertaken by Sacramento County to date. This $1.04 billion terminal modernization project, called the “Big Build,” is comprised of two individual buildings.

The facility boasts a new landside Central Terminal and the new 19-gate airside Concourse B, which are connected by an automated people mover. The two structures house passenger processing, international arrivals, passenger security checkpoints, in-line baggage screening, and more than 42,000 sq. ft of passenger amenity space. The design was inspired by the area’s rich history and culture. The design team at Corgan Associates in association with Fentress Architects created a world-class airport and a gateway to the Central Valley region while capturing a unique sense of place that represents Sacramento. In addition, the facility was designed with sustainability in mind. The result is a bright and airy space with abundant natural daylight reducing the need for artificial lighting and decreasing internal energy use. The project ultimately achieved LEED Silver certification.

For the terminal’s central spine, at left, field erection was sequenced to utilize the rigidity of the X-girders to minimize movements and the need for extensive temporary bracing. Photo courtesy of Buehler & Buehler Structural Engineers, Inc.

The exposed structural steel roof framing members create a dynamic rhythm of light and shadow, an effect inspired by Sacramento’s tree-lined streets. Wayfinding was integral to the design with unobstructed views across the public spaces, a visual connection to the central circulation spine, and ample outdoor views. The use of architecturally exposed structural steel (AESS) enhances the unique architectural expression and its use, prominent throughout the public areas, and achieved the desired visual quality. Achieving a roof structure reminiscent of a tree canopy for the Central Terminal involved the use of curved tapered steel plate girders spanning 120 feet which dynamically intersect in the middle of the structure.

In the concourse, the tapered steel plate girders span over 90 feet and include complex double curvature geometry to sculpt a roof structure that emulates the rolling hills surrounding Sacramento. Architectural detailing in both buildings included cladding the structural columns with steel plates to enhance structural performance and to provide concealed electrical and plumbing raceways.

For the terminal’s central spine, field erection was sequenced to utilize the rigidity of the X-girders to minimize movements and the need for extensive temporary bracing. Additionally, the joints provided improved thermal expansion characteristics for the concourse which is nearly one quarter of a mile long. Because much of the steel framing was exposed, the design and construction team worked closely to develop details that achieved the architectural vision and were also efficient to fabricate. The fabricators made extensive use of custom jigs and fixtures to position the members in the shop to minimize welding distortion in cruciform columns and AESS curved roof girders.

Field erection was sequenced to utilize the rigidity of the crossing girders in the central spine of the terminal to minimize the need for extensive temporary bracing. A system of temporary columns, guy cables and “king posts” with turnbuckles was utilized for numerous sloping columns and cantilever members to provide temporary support and fine adjustment of elevation and position.

Project team:

Owner

Sacramento County Airport System

Architect

Corgan Associates, Dallas, Texas, in association with

Fentress Architects, Denver, Colo.

Structural Engineer

Buehler & Buehler Structural Engineers, Inc.,

Sacramento, Calif., and

L.A. Fuess Partners (LAFP), Dallas, Texas

Structural Steel Subcontractors

Schuff Steel, Stockton, Calif., and

Herrick Steel, Stockton, Calif.

Contractors

Turner Construction /

Austin Walsh Construction Joint Venture,

Sacramento, Calif.

For more about the American Institute of Steel Construction, visit www.aisc.org.

Related Stories

Steel Buildings | Apr 17, 2021

Speed Core wall system is used for the second time in office building in San Jose

The construction method is expected to knock off three months from the project’s schedule.

Steel Buildings | Jun 17, 2020

America's structural steel industry remains a success story

That structural steel supply chain has remained robust, active, and ready to build tomorrow’s landmark structures.

Steel Buildings | May 26, 2020

Visionary footbridge/elevated park concept wins AISC’s Forge Prize

An innovative cantilevered pedestrian bridge and elevated park concept by Rosannah Harding and Matthew Ostrow of HardingOstrow took top honors.

Steel Buildings | Jan 3, 2020

5 reasons to enter the $20,000 Forge Prize

Calling all emerging architects. Don’t miss out on your chance to enter the $20,000 Forge Prize. Submissions for Stage 1 judging are due January 15.

75 Top Building Products | Dec 16, 2019

Top Structural Products for 2019

Inpro’s Fireline 140 fire barrier and Owens Corning’s Foamglas cellular glass insulation are among the 10 structural products to make Building Design+Construction's 2019 101 Top Products report.

75 Top Building Products | Dec 16, 2019

101 Top Products for 2019

Building Design+Construction readers and editors select their top building products for the past 12 months in the fourth-annual 101 Top Products report.

Architects | Dec 10, 2019

Calling all emerging architects: Enter to win the $20,000 Forge Prize

This annual steel design competition will recognize three Finalists ($10,000 each) and one Grand Prize Winner ($20,000 total) for their novel concepts in steel-based structures. Entries are due Jan. 15, 2020.

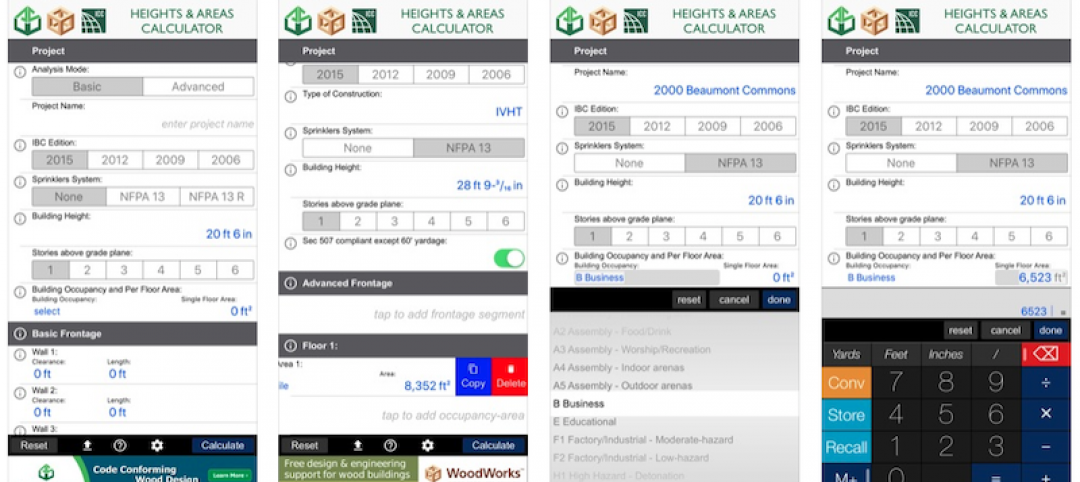

Codes and Standards | Sep 9, 2019

Free app calculates maximum allowable heights and areas for buildings

A free app that calculates the maximum allowable heights and areas for buildings of various occupancy classifications and types of construction has been released.

| Aug 26, 2019

New AISC guide tells how to design with structural steel

New AISC "Designing with Structural Steel - A Guide for Architects"

Steel Buildings | Feb 5, 2019

Thirteen Building Projects Win Top Steel Design Awards

A "baker's dozen" of structural steel projects have earned recognition in the 2019 Innovative Design in Engineering and Architecture with Structural Steel awards program (IDEAS2).