Sacramento International Airport’s Central Terminal and Concourse B is the largest public construction capital improvement project undertaken by Sacramento County to date. This $1.04 billion terminal modernization project, called the “Big Build,” is comprised of two individual buildings.

The facility boasts a new landside Central Terminal and the new 19-gate airside Concourse B, which are connected by an automated people mover. The two structures house passenger processing, international arrivals, passenger security checkpoints, in-line baggage screening, and more than 42,000 sq. ft of passenger amenity space. The design was inspired by the area’s rich history and culture. The design team at Corgan Associates in association with Fentress Architects created a world-class airport and a gateway to the Central Valley region while capturing a unique sense of place that represents Sacramento. In addition, the facility was designed with sustainability in mind. The result is a bright and airy space with abundant natural daylight reducing the need for artificial lighting and decreasing internal energy use. The project ultimately achieved LEED Silver certification.

For the terminal’s central spine, at left, field erection was sequenced to utilize the rigidity of the X-girders to minimize movements and the need for extensive temporary bracing. Photo courtesy of Buehler & Buehler Structural Engineers, Inc.

The exposed structural steel roof framing members create a dynamic rhythm of light and shadow, an effect inspired by Sacramento’s tree-lined streets. Wayfinding was integral to the design with unobstructed views across the public spaces, a visual connection to the central circulation spine, and ample outdoor views. The use of architecturally exposed structural steel (AESS) enhances the unique architectural expression and its use, prominent throughout the public areas, and achieved the desired visual quality. Achieving a roof structure reminiscent of a tree canopy for the Central Terminal involved the use of curved tapered steel plate girders spanning 120 feet which dynamically intersect in the middle of the structure.

In the concourse, the tapered steel plate girders span over 90 feet and include complex double curvature geometry to sculpt a roof structure that emulates the rolling hills surrounding Sacramento. Architectural detailing in both buildings included cladding the structural columns with steel plates to enhance structural performance and to provide concealed electrical and plumbing raceways.

For the terminal’s central spine, field erection was sequenced to utilize the rigidity of the X-girders to minimize movements and the need for extensive temporary bracing. Additionally, the joints provided improved thermal expansion characteristics for the concourse which is nearly one quarter of a mile long. Because much of the steel framing was exposed, the design and construction team worked closely to develop details that achieved the architectural vision and were also efficient to fabricate. The fabricators made extensive use of custom jigs and fixtures to position the members in the shop to minimize welding distortion in cruciform columns and AESS curved roof girders.

Field erection was sequenced to utilize the rigidity of the crossing girders in the central spine of the terminal to minimize the need for extensive temporary bracing. A system of temporary columns, guy cables and “king posts” with turnbuckles was utilized for numerous sloping columns and cantilever members to provide temporary support and fine adjustment of elevation and position.

Project team:

Owner

Sacramento County Airport System

Architect

Corgan Associates, Dallas, Texas, in association with

Fentress Architects, Denver, Colo.

Structural Engineer

Buehler & Buehler Structural Engineers, Inc.,

Sacramento, Calif., and

L.A. Fuess Partners (LAFP), Dallas, Texas

Structural Steel Subcontractors

Schuff Steel, Stockton, Calif., and

Herrick Steel, Stockton, Calif.

Contractors

Turner Construction /

Austin Walsh Construction Joint Venture,

Sacramento, Calif.

For more about the American Institute of Steel Construction, visit www.aisc.org.

Related Stories

Sponsored | BD+C University Course | May 10, 2022

Designing smarter places of learning

This course explains the how structural steel building systems are suited to construction of education facilities.

Sponsored | BD+C University Course | Apr 19, 2022

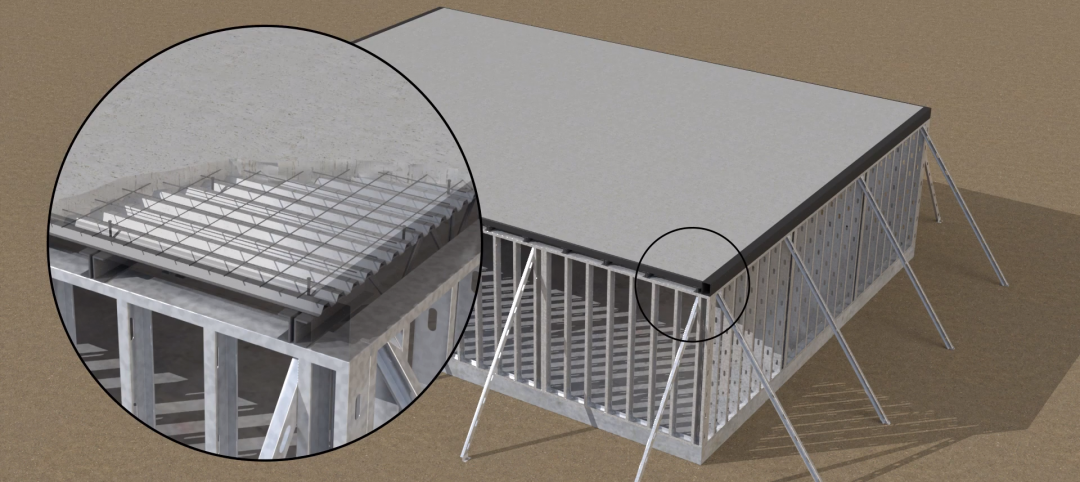

Multi-story building systems and selection criteria

This course outlines the attributes, functions, benefits, limits, and acoustic qualities of composite deck slabs. It reviews the three primary types of composite systems that represent the full range of long-span composite floor systems and examines the criteria for their selection, design, and engineering.

Contractors | Mar 28, 2022

Amid supply chain woes, building teams employ extreme procurement measures

Project teams are looking to eliminate much of the guesswork around product availability and price inflation by employing early bulk-purchasing measures for entire building projects.

Sponsored | BD+C University Course | Jan 30, 2022

Optimized steel deck design

This course provides an overview of structural steel deck design and the ways to improve building performance and to reduce total-project costs.

Sponsored | Steel Buildings | Jan 25, 2022

Structural Game Changer: Winning solution for curved-wall gymnasium design

Sponsored | Steel Buildings | Jan 25, 2022

Multifamily + Hospitality: Benefits of building in long-span composite floor systems

Long-span composite floor systems provide unique advantages in the construction of multi-family and hospitality facilities. This introductory course explains what composite deck is, how it works, what typical composite deck profiles look like and provides guidelines for using composite floor systems. This is a nano unit course.

Sponsored | BD+C University Course | Jan 12, 2022

Total steel project performance

This instructor-led video course discusses actual project scenarios where collaborative steel joist and deck design have reduced total-project costs. In an era when incomplete structural drawings are a growing concern for our industry, the course reveals hidden costs and risks that can be avoided.

Sponsored | BD+C University Course | Oct 15, 2021

7 game-changing trends in structural engineering

Here are seven key areas where innovation in structural engineering is driving evolution.