Katerra, a construction technology company, recently revealed plans to build an advanced manufacturing factory in California’s Central Valley. The Tracy, Calif., facility will produce building components such as wall panels, floor systems, roof truss assemblies, windows, cabinets, and finishes.

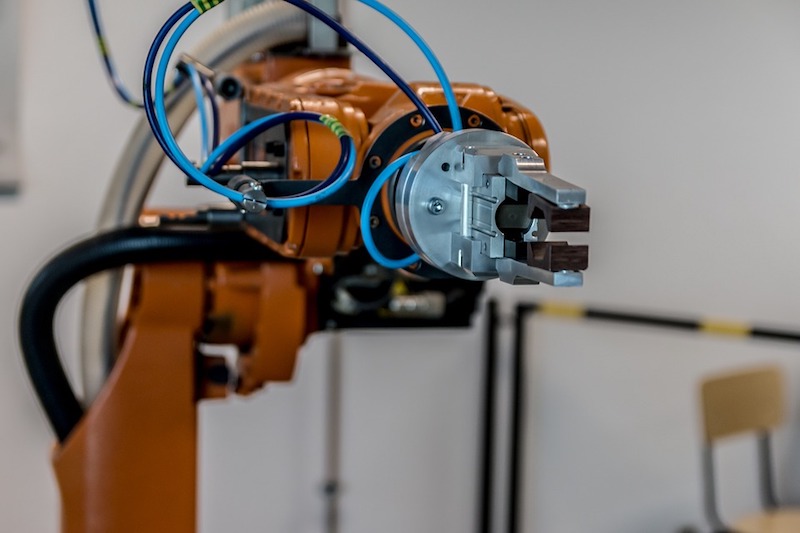

The 577,000-sf, factory will complement Katerra’s existing California operations, including its headquarters in Menlo Park and office in San Francisco. The new facility will differ from Katerra’s first, located in Phoenix, Ariz., by including significantly more automation, including fully automated wood frame wall production lines, automated floor lines, automated cabinet and finish areas, automated roof truss lines, an automated window line, and a light gauge steel production line.

See Also: Katerra, a tech-driven GC, plots ambitious expansion

The new facility will be located near rail, shipping ports, and freeways and create more than 500 jobs for the area. Production is slated to begin in 2019. Katerra is also in the process of building a mass timber manufacturing facility in Spokane, Wash., that will produce cross-laminated timber wall panels and floor systems when it becomes operational in 2019.

Related Stories

| Aug 11, 2010

AIA course: MEP Technologies For Eco-Effective Buildings

Sustainable building trends are gaining steam, even in the current economic downturn. More than five billion square feet of commercial space has either been certified by the U.S. Green Building Council under its Leadership in Energy and Environmental Design program or is registered with LEED. It is projected that the green building market's dollar value could more than double by 2013, to as muc...

| Aug 11, 2010

Integrated Project Delivery builds a brave, new BIM world

Three-dimensional information, such as that provided by building information modeling, allows all members of the Building Team to visualize the many components of a project and how they work together. BIM and other 3D tools convey the idea and intent of the designer to the entire Building Team and lay the groundwork for integrated project delivery.

| Aug 11, 2010

Great Solutions: Technology

19. Hybrid Geothermal Technology The team at Stantec saved $800,000 in construction costs by embedding geothermal piping into the structural piles at the WestJet office complex in Calgary, Alb., rather than drilling boreholes adjacent to the building site, which is the standard approach. Regular geothermal installation would have required about 200 boreholes, each about four-inches in diameter ...