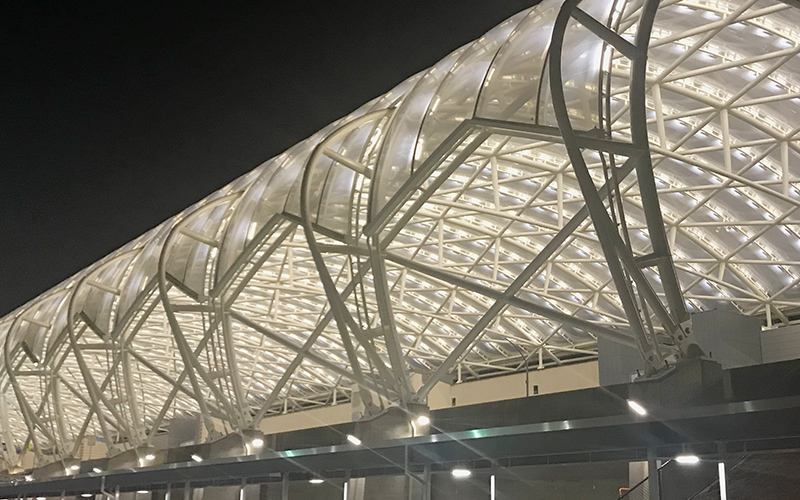

Hartsfield-Jackson Atlanta International, the world’s busiest airport, is in the midst of a $6 billion, 20-year expansion and modernization program. A major part of that program is an overhaul of the Central Passenger Terminal Complex (CPTC), which serves as the airport’s entrance and exit for all domestic traffic. As part of the CPTC updates, Atlanta commissioned architecture firm HOK to design a massive pair of canopies to stretch over curbside pickup and dropoff areas, protecting passengers from the elements and giving the airport a pair of iconic architectural pieces.

The Challenge

Building anything at the busiest airport in the world is bound to involve logistical challenges, but planners had a truly ambitious goal in mind for this project: Build two soaring canopies — 864 feet long, 72 feet tall and 194 feet wide, arching over eight lanes of traffic each — without disrupting airport operations or the 275,000 passengers who pass through daily. To accomplish this feat, designers had to figure out how to construct and install intricate steel diagrid lattices without closing traffic lanes or blocking airport entrances with construction work. Further, the new structures would have to be largely supported by existing construction, as installing extensive new supports or pilings would cause too much disruption to airport operations. That meant no new columns at the terminal curb and a limited ability to reinforce existing supports.

Modeling Minimizes Disruption

The first step was figuring out exactly how to design the lattice so it could be erected with as little disruption as possible. HOK’s designers used HOK STREAM, a proprietary parametric modeling and optimization tool, to plan the lattice’s structure, making the most of existing supports while minimizing the amount of retrofit work required. Additionally, analytic desktop models, wind tunnel testing and computational fluid dynamics were used to aid design, finding optimal structural load paths and planning for the large temperature variations between Atlanta’s hot summers and cool winters. Using these tools, designers were able to come up with a plan that would minimize required construction time and put two-thirds of the new load onto support piers that could be installed with minimal disruption, with the rest of the load carried by pre-existing columns.

Logistical Heavy Lifting

While every construction project has logistical components, the unique challenges facing the canopy designers meant logistics had to be top of mind from beginning to end. Major work was only possible during limited traffic shutdowns between 10:00 p.m. and 4:00 a.m. every day, so the steel had to be carefully fabricated to be rapidly erected in the available time. To make the best use of the time they had, the team created a 4D schedule that mapped out precisely when and where each piece had to be installed, detailed in a comprehensive 500-page plan. And to make sure that plan went off without a hitch, fabricators started working a full year before construction began, custom-making the components of the lattice’s 38 identical trusses out of more than 3,500 tons of domestic steel.

HSS Solve for Efficiency and Easy Erection

HSS from Atlas Tube helped designers find solutions to their logistical and structural challenges. Using 14", 18" and 20" HSS pipe for the trusses, fabricators were able to bend each section to precise tolerances and cut miters to exact specifications in order to minimize the time and material needed for on-site welding. The high strength-to-weight ratio of HSS helped as well, making it possible to design canopies strong enough to withstand structural and environmental forces with minimal new support.

An Award-winning Effort

Ultimately, all the planning paid off, and the second canopy was completed a month ahead of schedule in October 2019. By using high-efficiency HSS and advanced computer modeling, the team was able to create a pair of iconic landmarks for Atlanta’s gateway to the world without impeding the airport’s efficiency. And the world has taken notice, with the canopies winning several awards, including the American Institute of Steel Construction’s 2020 IDEAS² Award for Sculptures / Art Installations / Non-building Structures and an NCSEA Excellence in Structural Engineering Award in 2019.

Related Stories

Steel Buildings | Mar 9, 2018

New steel and aluminum tariffs will hurt construction firms by raising materials costs; potential trade war will dampen demand, says AGC of America

Independent studies suggest the construction industry could lose nearly 30,000 jobs as a result of administration's new tariffs as many firms will be forced to absorb increased costs.

Sponsored | Steel Buildings | Sep 1, 2017

Long-span steel roof framing provides airport with open spaces; Evokes natural wonders

The facility boasts a new landside Central Terminal and the new 19-gate airside Concourse B, which are connected by an automated people mover.

BD+C University Course | Aug 23, 2017

AIA course: New steel systems add strength and beauty

Advances in R&D are fostering new forms of structural and aesthetic steel.

| Jun 13, 2017

Accelerate Live! talk: A case for Big Data in construction, Graham Cranston, Simpson Gumpertz & Heger

Graham Cranston shares SGH’s efforts to take hold of its project data using mathematical optimization techniques and information-rich interactive visual graphics.

Structural Materials | Apr 3, 2017

Best of structural steel construction: 4WTC, Fulton Center, Pterodactyl win AISC IDEAS2 Awards

The annual awards program, sponsored by the American Institute of Steel Construction, honors the best in structural steel design and construction.

Wood | Jan 13, 2017

Steel and concrete's take on tall wood

The American Institute of Steel Construction contends that the steel industry is a “world leader” in using recycled material and end-of-life recycling, and has made strides to lower greenhouse gas emissions below regulatory requirements.

Steel Buildings | Sep 20, 2016

AIA Course: Steel on the rise in multifamily and taller mixed-use projects

Steel also has certain advantageous traits in terms of economics and sustainability, says Michael E. Liu, AIA, NCARB, Vice President/Principal, The Architectural Team.

Steel Buildings | Sep 15, 2016

New York’s Hudson Yards to feature 16-story staircase sculpture

The installation is designed by British architect Thomas Heatherwick and will be the centerpiece of the $200 million plaza project

Steel Buildings | May 5, 2016

10 building projects win top steel engineering and architecture awards

Held annually by the American Institute of Steel Construction (AISC), the IDEAS2 awards recognize exceptional structural steel projects across the country. The award is the highest honor for building projects by the structural steel industry in the U.S.