Ever since Trim-Tex rolled out their latest corner bead, Fast Edge®, late last year, it’s been called "the next generation of corner bead." Why? It advances drywall corner beads in a number of ways, but most notably, in the time it takes contractors to finish their corners and the amount of mud they'll use. And drywall finishers have taken note: The Fast Edge® family of corner beads is already Trim-Tex’s fastest-selling product line in their 51-year history. It's one thing to make bold claims — to tell you that this dynamic new corner bead is going to help contractors save time and material — and it's another thing to put them to the test. So that's exactly what they did.

The Fast Edge® Time and Material Study

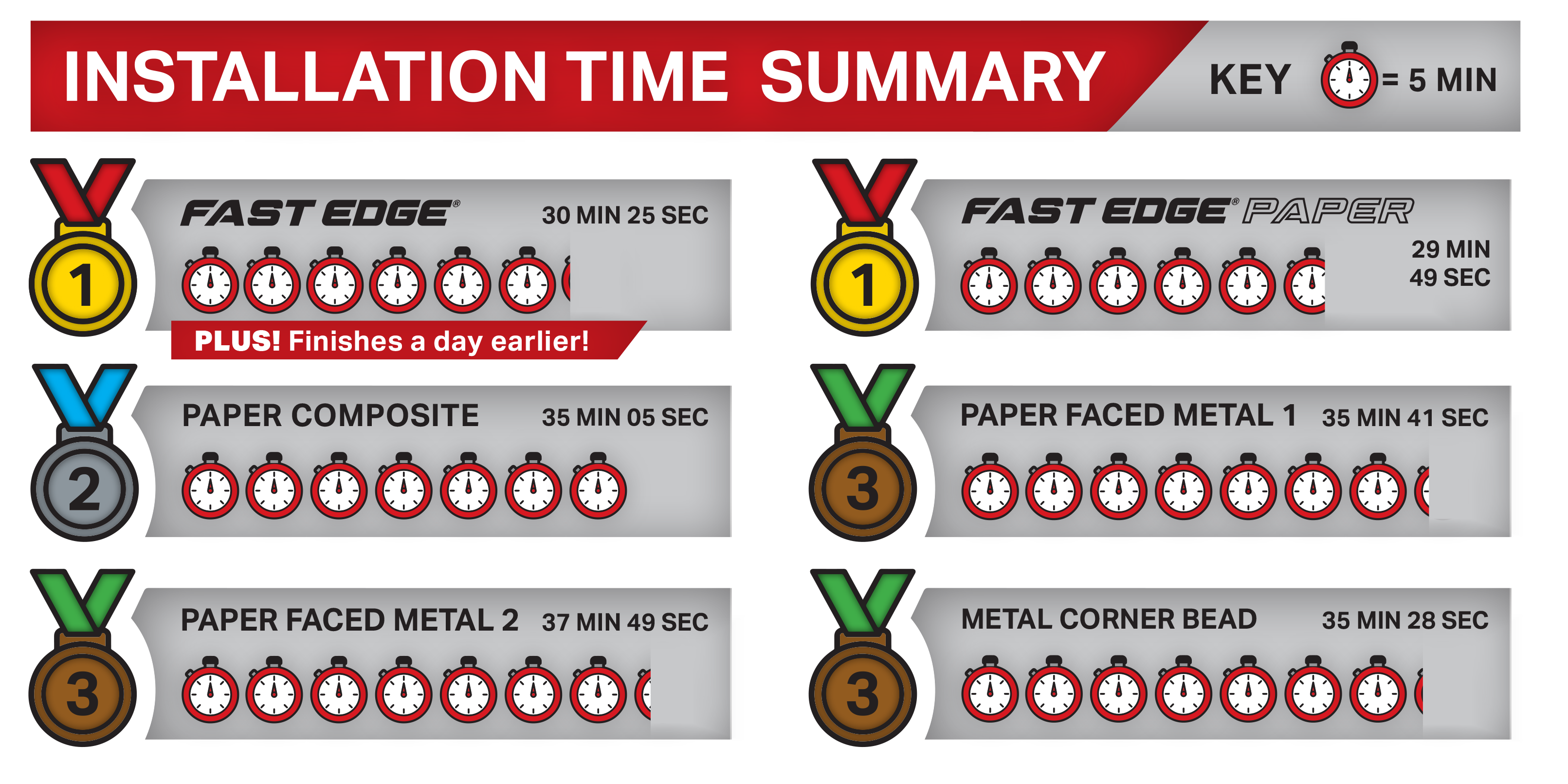

Trim-Tex recently brought two pro finishers to Trim-Tex HQ in Lincolnwood, IL, to put several of the top corner beads in the industry head-to-head against Fast Edge® and Fast Edge® Paper. For the sake of this study, each installed 10 eight-foot beads. After each installation, the clock stopped and elapsed time recorded. Those times, and the weight of the mud they used, were averaged between the two installers — here are the results.

INSTALLATION TIME

Based on the time it actually took to apply, install and finish these corner beads, Fast Edge® Paper and Fast Edge® walk away the winners. Between Fast Edge® and the average of the two brands of paper faced metal corner beads they tested, six minutes and 20 seconds of time savings for 10 pieces may not seem like much — but multiply that by 50, across an entire floor of a commercial building, and you're looking at a time savings of over five hours!

And that's not even counting the entire day that Fast Edge® will save you over its competition; it fully installs within just 24 hours, without ever having to touch quickset or hot mud. Factor in the time it takes to get back to the jobsite the next morning to finish the job, and the labor costs that will add, and Fast Edge® has a clear competitive advantage.

FINAL RESULTS: Fast Edge® is 13% faster on average to install than paper composite, and 17% faster than paper faced metal beads, not even counting the entire day saved to finish each bead.

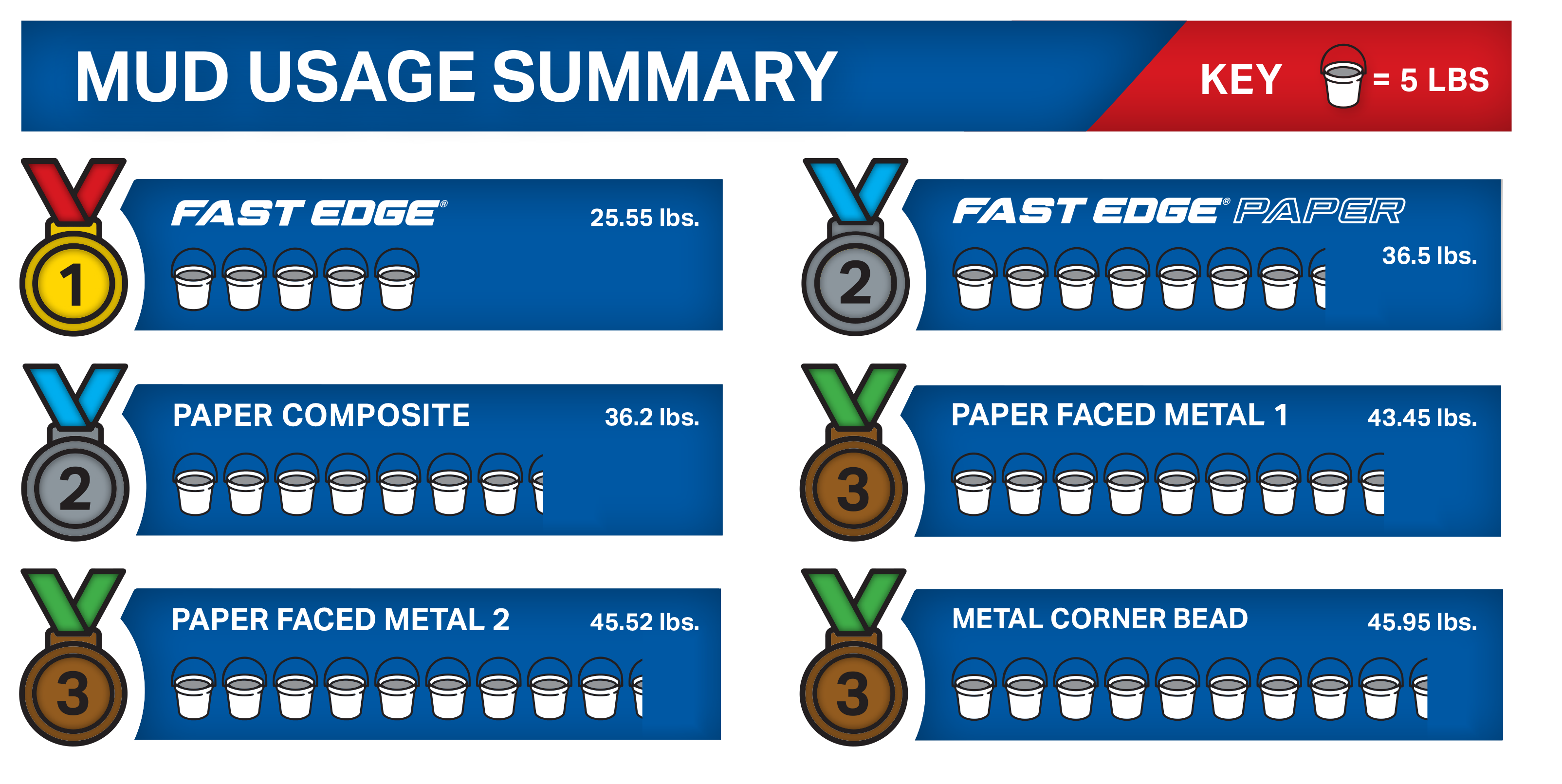

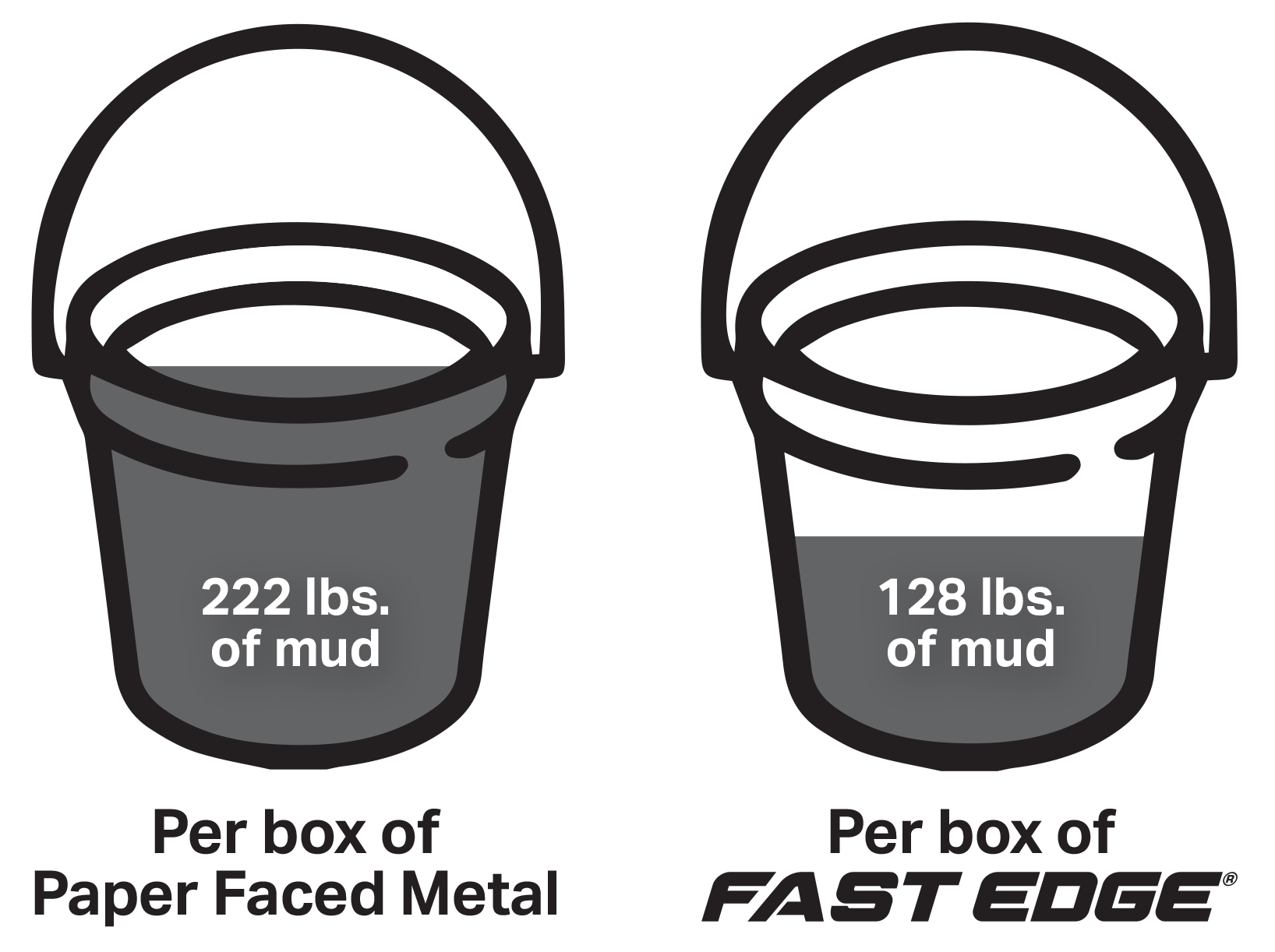

MUD USAGE

When it comes to saving on material, there's really nothing like Fast Edge® out there. For just these 10 eight-foot pieces, it accounts for a savings of 19 pounds of mud over the average of paper faced metal beads. For a full box of Fast Edge® (50 pieces), that savings goes up to 95 pounds. Besides cutting your mud expenses almost in half, that's 95 pounds you're not lugging around, installing and mixing at the jobsite day in and day out, for every box of eight-foot corner beads.

FINAL RESULTS: Fast Edge® uses 30% less mud on average than paper composite, and 43% less mud than paper faced metal beads.

This time and material study set out to prove that Fast Edge® performs better than the competition, and the results speak for themselves.

The savings on both time and material are just the beginning of the advantages Trim-Tex's Fast Edge® family provides. We haven't even touched on how much better these vinyl drywall corner beads perform when you try to damage them, or how our patented Mud Lock Technology creates a stronger bond between the bead and the drywall. To learn more about all of these benefits Fast Edge® provides, as well as those of all the products Trim-Tex has been perfecting over the last 51 years, visit www.Trim-Tex.com.

Related Stories

Sponsored | Voice of the Brand | Jun 5, 2023

Sustainable, Award-winning Design gives New Life to Parkland Hospital

Built in 1954, the Dallas Parkland Hospital had become severely overcrowded and outdated. The largest public healthcare project in the country to be built in one phase, this AIA award-winning, LEED Gold project doubled the size of the old facility. This remarkable design incorporates over 4.5 acres of ALPOLIC MCM.

Sponsored | Voice of the Brand | Mar 31, 2023

Considerations When Specifying in Extreme Weather Zones

Why Choose an IMP in an Extreme Weather Zone?

Sponsored | Voice of the Brand | Jul 29, 2022

River City: A New Gateway for the City of Toronto Clad in ALPOLIC MCM

Versatile and sustainable, ALPOLIC® MCM helped redefine the cityscape in an area of Toronto most in need of urban redevelopment. A project 15 years in the making, the abandoned industrialized zone by the West Don Lands has been transformed into something inspirational.

Sponsored | Voice of the Brand | Jun 1, 2022

High-Rise Buildings Stand Out with High-Style Metal Cladding

Metal wall panel systems provide a cost-effective, attractive solution for high-rise buildings.

Sponsored | Voice of the Brand | Jan 27, 2022

A Modern Approach to Labor in the Construction Industry

The COVID-19 pandemic disrupted and reshaped norms in the workforce and the ongoing labor shortage can be felt in every industry. Innovations to go faster, maintain safety, minimize learning curves, and drive down costs are becoming imperatives for companies to stay competitive in the construction industry.

Sponsored | Voice of the Brand | Dec 2, 2021

How Creativity Takes Shapes

Architects charged with developing new buildings are increasingly seeking ways to stretch the limits of their creativity while also delivering on durability and long-term performance when it comes to the building envelope. With a host of engineered building enclosure systems, Sto® serves as a key partner in this endeavor.

Sponsored | Voice of the Brand | Nov 18, 2021

The Beauty is in the Details

Color capabilities with Sherwin-Williams Coil Coatings are nearly limitless. Our line of Fluropon® coil and extrusion metal coating systems let our customers explore new color spaces using a wide array of gloss, effects and print options. With over 50,000 colors offered, we can color match almost any look you dream up.

Sponsored | Voice of the Brand | Sep 2, 2021

Protect Your Walls and Sloped Roofs with a Smarter Sheathing System

Integrated Continuous Insulation’s Role in the Ever-Changing Construction Landscape