In its prefabrication factory in Appleton, Wis., The Boldt Company, a national general contractor, is manufacturing modules for STAAT Mod, a prefab modular solution designed by HGA for assembling field hospitals capable of providing airborne infection isolation rooms.

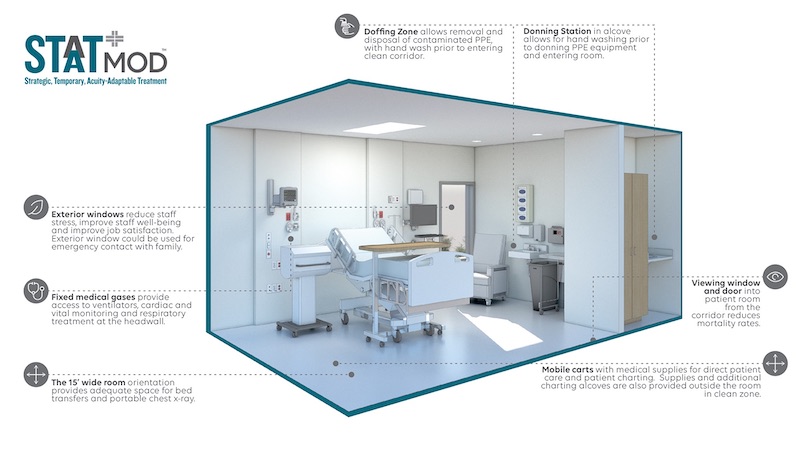

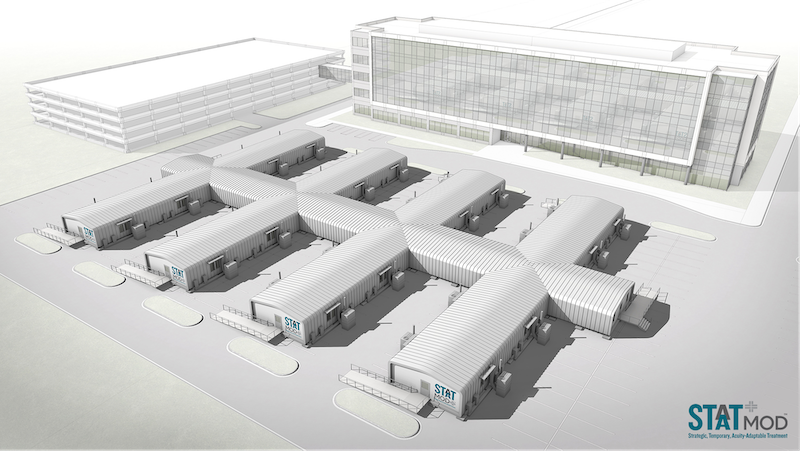

STAAT is an acronym for Strategic Temporary Acuity-Adaptable Treatment. The isolation rooms are designed with enough clearance for safe bed transfers, and can accommodate equipment and a reclining chair. The system, which is expandable, includes flexible support spaces, three-bay negative pressure units, an intake module, equipment room and staff work area, clean utility and medication/nourishment spaces, staff lounges and private work areas, and the electrical/mechanical infrastructure needed for operations.

Boldt currently has seven modules in various stages of production for an unnamed customer on the East Coast. (It declined to make public that customer’s name because the contract hadn’t been finalized at presstime.)

The building team on this project includes the mechanical contractor Tweet/Garot, the electrical engineer Faith Technologies, and the medical equipment planning firm IMEG. Information about STAAT Mod, and an animated video of how this system comes together, can be viewed and downloaded here.

Kurt Spiering, a healthcare market sector leader for HGA, notes that modularization has been A factor in the healthcare arena for the past six to eight years, partly because of the industry’s construction labor shortages. “It’s been in our blood for a while.” The challenge in developing STAAT Mod, he explains, was “maintaining the quality of care using different materials, and building something within three weeks.”

Boldt started exploring prefabrication for a 274-bed acute care hospital it built—in partnership with Herrero Builders— a few years ago for Sutter Health in San Francisco. The hospital sits on a one-block lot that had virtually no drop-off area available for materials. For that project, Boldt put up a temporary factory on Treasure Island, where it produced components like water closets and drinking fountain stations.

It then had a client in Chicago, Advocate Aurora Health, for which it produced a proof-of-concept modular master plan for healthcare clinics, medical office buildings, and ambulatory facilities. “We built the prototype in our Appleton factory, and drove it around the country” to test its durability, says Dave Kievet, Boldt’s COO.

STAAT Mod is designed and engineered to be expandable to meet the community's needs.

Then, he says, “the coronavirus hit.” Boldt began contacting some of its long-standing design and building partners to figure out how to develop a modular system with negative pressurization. In that endeavor, Boldt consulted with Theda Care and Froedtert Hospital in Wisconsin.

The Boldt Company is one of the industry’s leading proponents of Integrated Lean Project Delivery to control costs, increase the speed of construction, and drive out waste. Kievet says that ILPD allowed the building team to design and develop STAAT Mod “very quickly.”

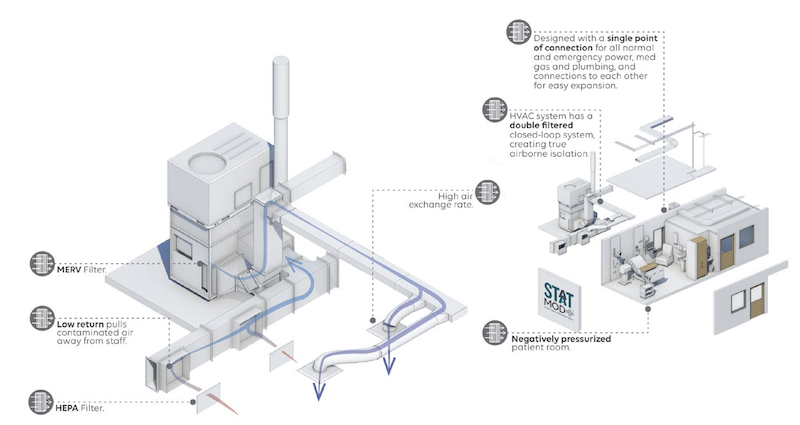

Spiering says that choices were made around two priorities: staff and patient safety, and getting good clinical outcomes. Jeff Harris, HGA’s director of engineering, adds that the building team took a “kit of parts” approach, which included choosing to use a standard 3- to 4-ton rooftop air handling unit that could service a couple of rooms that are designed with oversized ducts. The rooms that are negative pressurized draw air through HEPA filters.

Now that the U.S. Army Corps of Engineers is supervising the conversion of spaces like convention centers to alternate patient care facilities, HGA and Boldt views the states, which are coordinating these conversion efforts, as the primary buyers for STAAT Mod. Since it made public information about STAAT Mod, Boldt has had conversations with at least 20 potential customers, says Stacy Robben, the firm’s Vice President of Business Development.

Kievet estimates that once an order is placed, Boldt can get the first module up and operational within 14 to 17 days, and complete an entire order within 20 to 28 days. “The target is to get the completion down to 14 days,” he says. The price of the system will vary by the number of modules used. HGA|Boldt’s pricing sheet states that a two-room airborne isolation room would cost $335,000. A three-bed open bay negative pressure modular $317,000. So a two-tier system with 32 isolation rooms and all the other bells and whistles would run about $8.3 million.

This illustration shows the system's air handling and filtration mechanics.

Boldt sees three different practical applications for STAAT Mod: as supplemental interior isolation rooms within an existing system of care; as a modular system that’s connected to an existing hospital’s infrastructure, built (theoretically) on that facility’s parking lot; and as a self-sufficient temporary hospital with infrastructure.

STAAT Mod could be used to treat a hospital’s most severe cases, freeing up hospital and clinic beds for procedures like elective surgeries, which is where many healthcare systems derive a substantial portion of their revenues. Kievet says it’s conceivable that modules could be disassembled and reassembled as needed, or built on foundations for more permanent use.

Boldt has formed alliances with several other prefabrication firms in different parts of the country, including Southland Industries, to expand its capacity to provide STAAT Mod systems across the U.S. Boldt has 14 offices in the U.S., and healthcare is one of nine industry sectors it serves.

Related Stories

| Mar 25, 2020

Designing public health laboratories to safeguard researchers during pandemics

As laboratory designers, we want to shed light on a subset of our population critical to protecting us from, and preventing the spread of, severe outbreaks: public health researchers.

Market Data | Mar 23, 2020

Coronavirus will reshape UAE construction

The impact of the virus has been felt in the UAE, where precautionary measures have been implemented to combat the spread of the virus through social distancing.

Coronavirus | Mar 21, 2020

Perkins and Will’s CEO sees a light at the end of COVID-19 tunnel

Phil Harrison says the virus outbreak could make more clients see the connection between design and wellbeing.

Coronavirus | Mar 21, 2020

Construction business and union leaders call on government officials to include construction as an 'essential service' during shutdowns

The chief executive officer of the Associated General Contractors of America, Stephen E. Sandherr, and the President of North America’s Building Trades Unions, Sean McGarvey, issued the following joint statement urging Government Officials to Exempt Construction Work from Regional, State and Local Work Shutdowns.

Coronavirus | Mar 21, 2020

Associated General Contractors launches eight-part webinar series around COVID-19

The programming, which begins Monday, will offer advice on how businesses might need to adjust during the virus.

Coronavirus | Mar 20, 2020

BD+C research: The AEC industry braces for tough sledding in the coming months amid COVID-19 outbreak

A new BD+C poll of U.S. architecture, engineering, and construction firms finds that companies are anticipating project postponements and delays.

Coronavirus | Mar 20, 2020

Pandemic has halted or delayed projects for 28% of contractors

Coronavirus-caused slowdown contrasts with January figures showing a majority of metro areas added construction jobs; Officials note New infrastructure funding and paid family leave fixes are needed.

Coronavirus | Mar 20, 2020

AIA implores Congress to provide relief to business owners and employees

The American Institute of Architects (AIA) 2020 President Jane Frederick, FAIA, and EVP/Chief Executive Officer Robert Ivy, FAIA, are urging Congress to address the critical needs of business owners and employees during the COVID-19 pandemic.

Coronavirus | Mar 20, 2020

Extending care capacity as COVID-19 grows

Coronavirus threatens to overwhelm the U.S. healthcare system. LEO A DALY’s health practice leader offers some innovative ideas for expanding access.

Coronavirus | Mar 19, 2020

Positive vibes: Let's take a look at the brighter side of these crazy times

Perhaps now is a good time to take a page from Monty Python's book and look on the bright side of life. So let's push aside the doom and gloom for a bit and bring a little positivity to these strange times we all currently find ourselves in.