Cherokee Nation Entertainment’s 10,000-sq.-ft. Ramona Casino features a unique style that was both challenging and rewarding to create. The curved nature of the building’s exterior required multiple shades and profiles of metal panels, plus clever installation work by the contractor, Abbco Roofing in Broken Arrow, Okla., which was up to the challenge.

Located in Ramona, Okla., the casino was built on a 20-acre site near an existing casino. Selser Schaefer Architects in Tulsa, Okla., developed a phased master plan that enabled consistent casino operations in a temporary facility, while the permanent facility was completed. Because Ramona is where the first commercial oil well was drilled in what would become Oklahoma, the casino’s design is reminiscent of the time period from 1887 to 1906. Two oil derricks at the casino’s main entrance signify the beginning of the petroleum industry.

Selser Schaefer Architects states that the curved building form relates to the fluidity of oil, while breaking down the general rectangular floor plan to create a more appealing look from the nearby highway. Material choices such as copper panel and field stone were selected for Cherokee Nation cultural significance as well as function. The design of the casino and its concert venue incorporates clean lines and straight-forward materials. The interior colors and textures reflect the cultural integrity of the oil boom time period. Slate and copper ceiling elements create an exciting environment that permeates the entire gaming floor.

Abbco Roofing completed the metal panel work for this architecturally unique project, including the installation of wall and soffit panels in a pattern that features multiple shades of red. “The walls, as you can see, were curvilinear, and both concave and convex in style. The reveal detail was the biggest challenge by far,” says Dave Stanley, owner, Abbco Roofing.

“The reveal detail looked like a hat channel recessed in the wall and had to curve with the wall. This could not be roll-formed. We made the reveal in 10-ft. lengths in the shop and then turned the hat up and saw-cut it to enable us to bend it to the wall. The bottom of the hat then showed the saw joints and we covered it with flat metal to conceal the joints,” Stanley explains.

The design process at Selser Schaefer is always collaborative, and the firm works to bring its clients the value of timeless, sustainable architecture that does good things for people, communities and the environment. This project is no exception; everyone came together to develop a project that balances the functional needs and goals with an elegantly designed casino.

The general contractor was RM Builders of Muskogee, Okla. Petersen Aluminum metal panels were manufactured in Petersen’s Tyler, Texas, plant. Abbco has used Petersen Aluminum since 1974. “Trust, loyalty and the ease of the working relationship has to be superior in every fashion, and the support I get from the Tyler, Texas, facility is great,” Stanley says.

The new casino includes the following Petersen Aluminum products: 1,022 sq. ft. of 12-in perforated flush panel in Colonial Red; 20,436 sq. ft. of 12-in. 24-gauge flush panel in custom Bright Red and Copper Penny with stiffening beads; 11,033 sq. ft. of 16-in. 24-gauge horizontal wall panel in Slate Gray; 360 sq. ft. of 36-in. 7.2 panel in 24 gauge Slate Gray; 6,596 sq. ft. of 24-gauge 7/8-in. corrugated in Slate Gray; 13,120 sq. ft. of flat sheet in 24 gauge and custom Bright Red, Copper Penny and Slate Gray.

When the project was completed, Stanley had time to step back and observe what Abbco had accomplished. “It dawned on me how special it was and how proud I was to be involved, and of our crew’s hard work,” he says.

Related Stories

| Jul 18, 2014

Top Contractors [2014 Giants 300 Report]

Turner, Whiting-Turner, Skanska top Building Design+Construction's 2014 ranking of the largest contractors in the United States.

| Jul 18, 2014

Engineering firms look to bolster growth through new services, technology [2014 Giants 300 Report]

Following solid revenue growth in 2013, the majority of U.S.-based engineering and engineering/architecture firms expect more of the same this year, according to BD+C’s 2014 Giants 300 report.

| Jul 18, 2014

Top Engineering/Architecture Firms [2014 Giants 300 Report]

Jacobs, AECOM, Parsons Brinckerhoff top Building Design+Construction's 2014 ranking of the largest engineering/architecture firms in the United States.

| Jul 18, 2014

Top Engineering Firms [2014 Giants 300 Report]

Fluor, Arup, Day & Zimmermann top Building Design+Construction's 2014 ranking of the largest engineering firms in the United States.

| Jul 18, 2014

Top Architecture Firms [2014 Giants 300 Report]

Gensler, Perkins+Will, NBBJ top Building Design+Construction's 2014 ranking of the largest architecture firms in the United States.

| Jul 18, 2014

2014 Giants 300 Report

Building Design+Construction magazine's annual ranking the nation's largest architecture, engineering, and construction firms in the U.S.

| Jul 7, 2014

7 emerging design trends in brick buildings

From wild architectural shapes to unique color blends and pattern arrangements, these projects demonstrate the design possibilities of brick.

| Jul 2, 2014

Emerging trends in commercial flooring

Rectangular tiles, digital graphic applications, the resurgence of terrazzo, and product transparency headline today’s commercial flooring trends.

| Jun 18, 2014

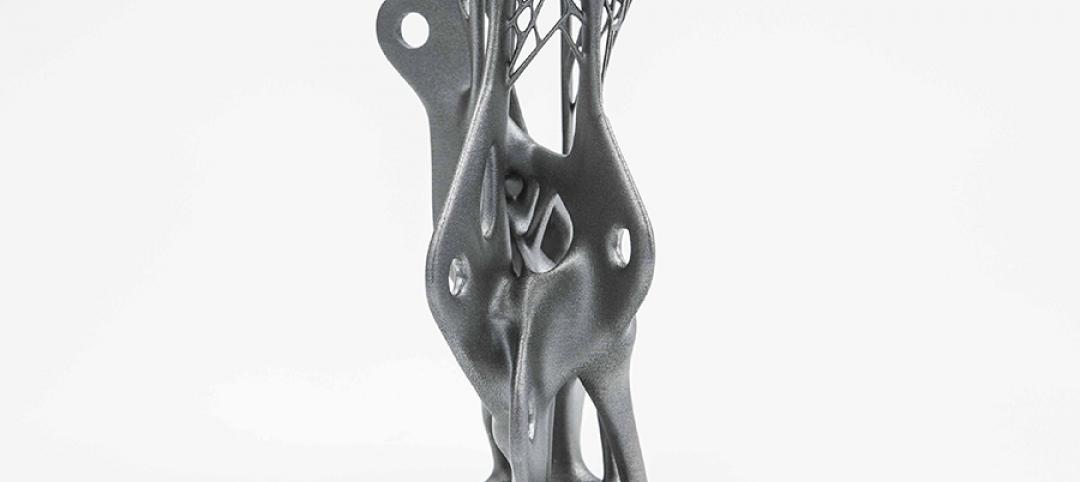

Arup uses 3D printing to fabricate one-of-a-kind structural steel components

The firm's research shows that 3D printing has the potential to reduce costs, cut waste, and slash the carbon footprint of the construction sector.

| Jun 12, 2014

Austrian university develops 'inflatable' concrete dome method

Constructing a concrete dome is a costly process, but this may change soon. A team from the Vienna University of Technology has developed a method that allows concrete domes to form with the use of air and steel cables instead of expensive, timber supporting structures.